Adjusting end clearance, Pressure relief valve instructions, Danger – Viking MAG DRIVE 855 User Manual

Page 13

SECTION TSM

685.2

ISSUE

C

PAGE 13 OF 16

ADJUSTING END CLEARANCE

Table 7-A provides standard operating end clearance

for this pump. Use either of the following procedures to

properly adjust the end clearance when replacing shims or

reassembling the pump.

fIGURE 21

PRESSURE RELIEf VALVE INSTRUCTIONS

Before opening any Viking pump liquid cham-

ber (pumping chamber, reservoir, relief valve

adjusting cap fitting etc.) Be sure:

1. That any pressure in chamber has been

completely vented through suction or

discharge lines or other appropriate openings

or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or made

non- operational so that it cannot be started

while work is being done on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material

safety data sheet (msds) for the liquid to be

sure these precautions are understood.

failure to follow above listed precaution-

ary measures may result in serious injury or

death.

DANGER !

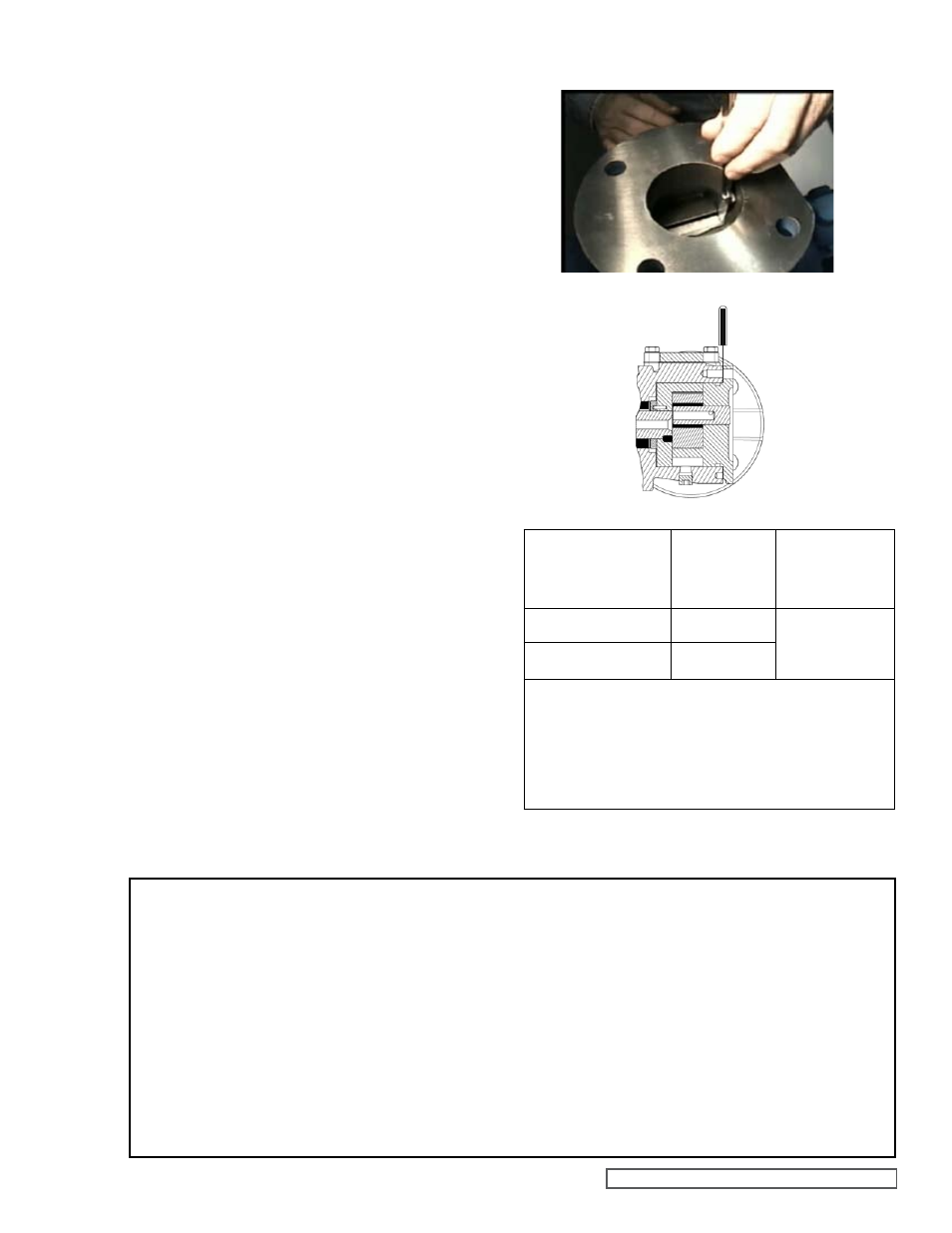

fIGURE 20

PROCEDURE A

After the rotor has been installed and the locknut has been

positioned and retained, insert a feeler gage of the proper

end clearance thickness into the port at the root (base) of

two rotor teeth

(See figure 20). For convenience, remove

the head O-ring and install one 0.007” shim onto the head.

With the idler on the idler pin, place the head into the pump

casing. With the capscrews tight, the feeler gage should fit

snugly between the idler and the rotor face; otherwise shims

should be added or reduced in thickness until the proper

clearance is attained.

PROCEDURE B

If the pump is in line and ports are not accessible, remove

the head and shims. Put the head back on (without shims)

and measure the gap as shown

(See figure 21). After

determining the gap between the head and casing, select

a combination of shims equal to the measured gap plus

the desired end clearance

(See figure 21). Remove head,

install shims then install head. Tighten the head capscrews

and check the pump clearance by making sure the pump

turns freely by hand. Since the pump shaft is concealed, it

is best to work up to the proper end clearance because it is

difficult to determine when there is too much end clearance

with this approach.

Head

end

Coupling

end

NORMAL

1

END

CLEARANCE

(inch)

SET Of HEAD

SHIMS INCLUDES

AS, AK, AL 855

0.005

(1) .007

(1) .005

(2) .002

(2) .001

KE, KKE 855

0.005

1

End Clearances are adequate for viscosities up to 2500 SSU /

540 cSt (SAE 40 lube oil at room temperature). Higher viscosities

require additional clearances. As a general rule the end clearance

is doubled for higher viscosities. For specific recommendations for

end clearance for viscosity or for operating temperatures above

225 °F (107 °C), check with your Viking representative or consult

the factory.

TABLE 7-A