Special information, Caution, Danger – Viking MAG DRIVE 855 User Manual

Page 3

SECTION TSM

685.2

ISSUE

C

PAGE 3 OF 16

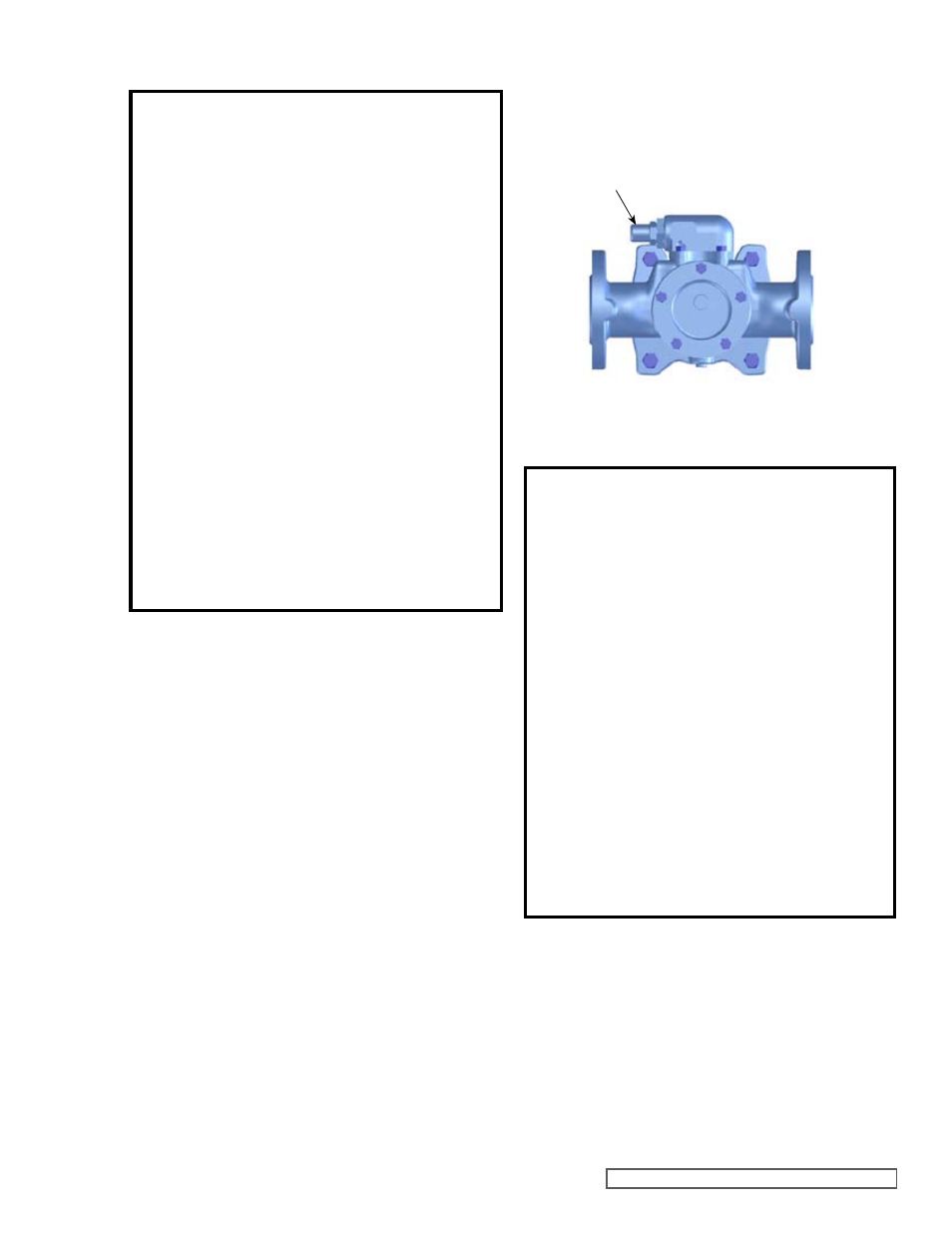

fIGURE 3

RELIEf VALVE POSITION

SPECIAL INfORMATION

ROTATION: Viking Mag Drive® pumps are designed to run

in either direction. See

PUMP ROTATION, page 11.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive displacement pumps and must

be provided with some sort of pressure protection. This

may be a relief valve mounted directly on the pump, an

inline pressure relief valve, a torque limiting device or a

rupture disk. Do not rely on decoupling of magnets for

protection from over pressure; this may result in damage

to the magnets, pump, or other equipment.

2. Relief valves are mounted as standard on the casing of

AS, AK,AL,KE and KKE size pumps.

3. If the pump rotation is to be reversed during operation,

pressure protection must be provided on both sides of

the pump.

4. The relief valve adjusting screw cap must always

point towards the suction side of the pump.

See

figure 3. If the pump rotation is reversed, remove

the pressure relief valve and turn end for end

(see

PUMP ROTATION, page 11 for additional information.

5. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

For additional information on pressure relief valves, refer to

Technical Service Manual TSM000 and Engineering Service

Bulletin ESB-31.

CAUTION !

Rare earth magnets used in couplings have

extremely strong magnetic fields capable of

changing performance or damaging items

such as the following:

Pacemakers

Metal Implants

Watches

Computers & disks

Credit Cards

Completely assembled magnetic couplings

will not affect items listed above – only disas-

sembled components.

There are no known harmful effects of these

magnetic fields on the human body.

RELIEF VALVE ADJUSTING

SCREW CAP

SUCTION

DISCHARGE

DANGER !

Before opening any Viking pump liquid cham-

ber (pumping chamber, reservoir, relief valve

adjusting cap fitting etc.) Be sure:

1. That any pressure in the chamber has been

completely vented through the suction

or discharge lines or other appropriate

openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or made

non- operational so that it cannot be started

while work is being done on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material

safety data sheet (MSDS) for the liquid to be

sure these precautions are understood.

failure to follow above listed precaution-

ary measures may result in serious injury or

death.