Operation, 2 boom unit pre-operation inspection and service – Tiger RBF-14C User Manual

Page 61

Operation Section 4-11

OPERATION

RBF-14C 07/04

© 2004 Alamo Group Inc.

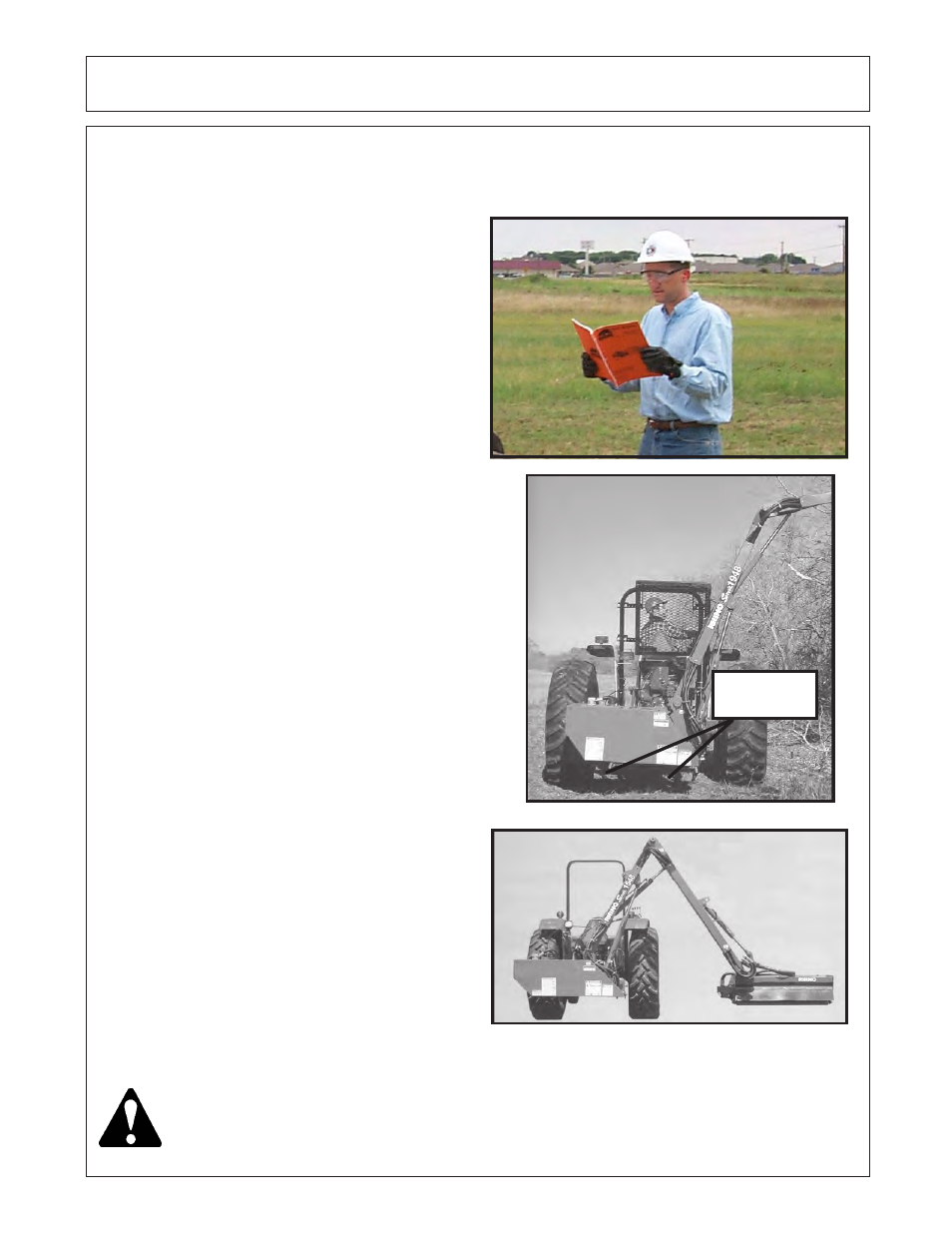

6.2 Boom Unit Pre-Operation Inspection and Service

Inspect and service the boom arm and head prior to operation. Damaged and/or broken parts should be repaired

and/or replaced immediately. To ensure the unit is ready for operation, conduct the following:

¾ Ensure that the Manual Canister is secured to the

Boom unit with the Operator’s Manual inside.

¾ Ensure all decals are in place and legible. Replace

missing, worn, and non-legible decals.

NOTE: The mower Operator’s Manual and affixed

Decals contain important instructions on the safe and

proper use of the mower. Maintain these important

safety features on the mower in good condition to ensure

the information is available to the operator at all times.

BOOM ARM ASSEMBLY

¾ Inspect condition of each arm section weldment

¾ Ensure all pins are in place.

¾ Ensure all bolts and screws are properly installed.

¾ Check condition of teflon bushings at boom pivot

points.

¾ Ensure each hydraulic cylinder is installed and

retained correctly. Ensure the proper size pins

are used to retain the cylinders in place and are

secured properly.

¾ Ensure that all joints are lubricated. See

Maintenance Section for Lubrication Chart.

FRAME ASSEMBLY

¾ Inspect condition of mounting frame weldment.

¾ Inspect condition of King Post frame.

¾ Ensure all bolts and screws are in position and are

properly torqued.

¾ Ensure all pins are in place and fastened with

screws.

¾ Ensure frame is properly mounted to tractor and

hardware is properly installed and tightened.

WARNING!

Never attempt to lubricate, adjust, or remove material from the Implement while it is in motion

or while tractor engine is running. Make sure the tractor engine is off before working on the

Implement.

(SG-20)

Frame

Weldment