Appendix i: input wiring requirements – Thermal Dynamics (a Thermadyne Company) Merlin 3000 User Manual

Page 71

Manual 0-2533

67

APPENDIX

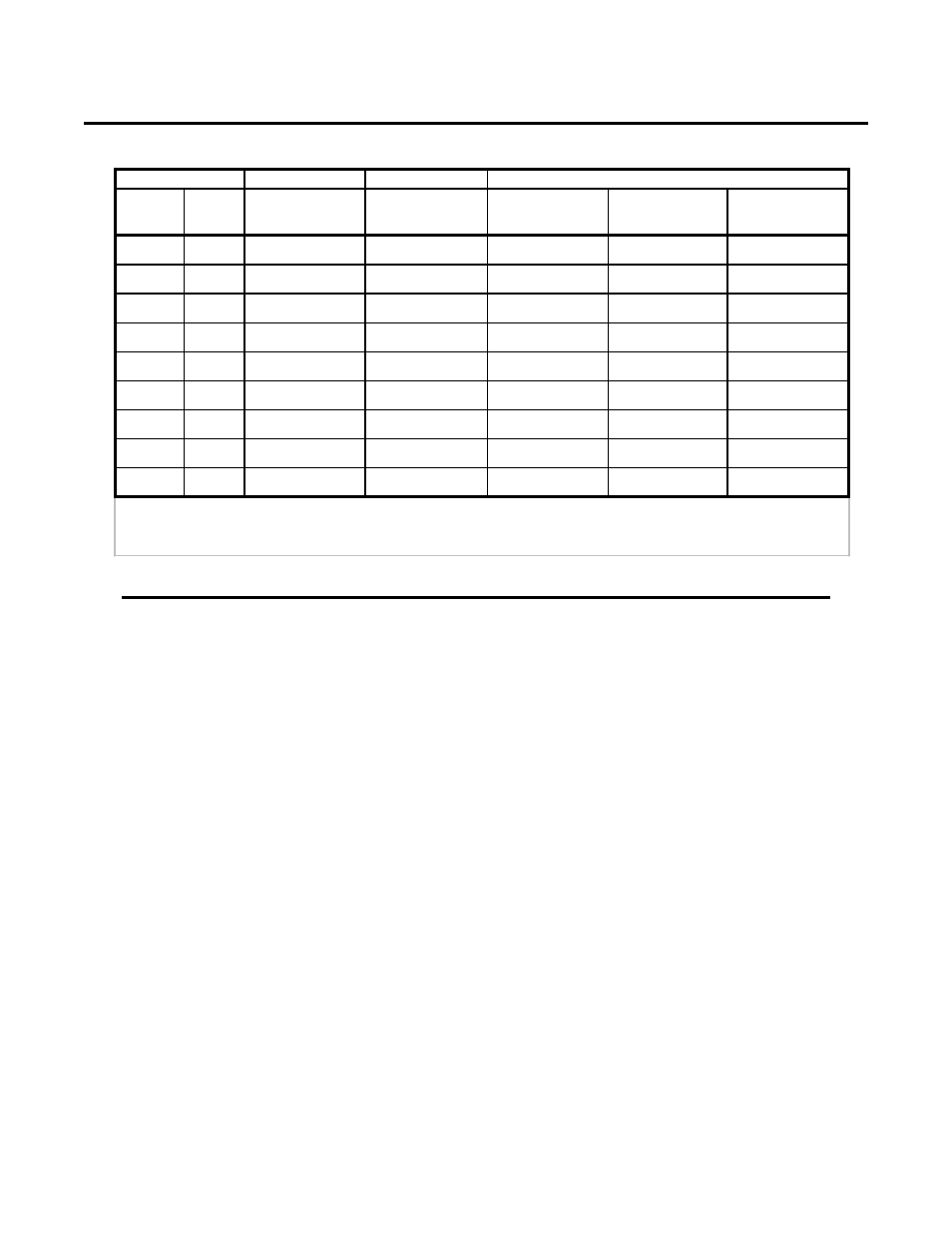

APPENDIX I: INPUT WIRING REQUIREMENTS

In p u t

P o w er In p u t

C u r r en t

S u g g e st ed S iz es ( S ee N o te s)

V o lta g e

F r e q .

3- P h

3- P h

F u se ( A m p s)

W ir e (A W G )

W ir e (C an ad a)

( V o lt s)

( H z )

( kV A )

( A m p s )

3- P h

3- P h

3- P h

200

50/60

34

98

110

A W G 2

2

208

50/60

34

95

110

A W G 2

2

220

50/60

34

89

100

A W G 2

2

230

50/60

34

85

100

A W G 4

2

380

50/60

34

51

60

A W G 6

6

415

50/60

34

47

60

A W G 8

6

460

50/60

34

42

50

A W G 8

6

506

50/60

34

40

45

A W G 8

6

575

50/60

34

34

40

A W G 8

6

Li n e V o l tages w i th S ugges ted C i r c ui t P r otec ti on an d W i r e S i z es

B as ed on N ati ona l E l ec tr i c C ode and C ana di an E l ec tr i c al C ode

NOTES

Refer to Local and National Codes or local authority having jurisdiction for proper wiring requirements.

Cable size is de-rated based on the Duty Cycle of the equipment.

The suggested sizes are based on flexible power cable with power plug installations. For hard-wired installations

refer to local or national codes.

Cable conductor temperature used is 167° F (75° C).

An energy limiting fuse UL Class RK-1 (examples: BUSS LPS/LPN-RK or Gould-Shawmut AZK-A6K) should be

used to minimize damage to Plasma Cutting, Welding or power distribution equipment.

NEVER

use replaceable element fuses like UL Class H, or "one-time" fuses like UL Class K5.