Section 4: service troubleshooting diagnostics, 01 introduction, 02 periodic inspection & procedures – Thermal Dynamics (a Thermadyne Company) Merlin 3000 User Manual

Page 19: Section 4, Service troubleshooting diagnostics

Manual 0-2533

15

SERVICE TROUBLESHOOTING

SECTION 4:

SERVICE

TROUBLESHOOTING

DIAGNOSTICS

4.01 Introduction

This Section provides service diagnostics for the Merlin

3000 Power Supply, allowing the Technician to islolate

any faulty Subassemblies. Refer to Section 5, Repairs &

Replacement Procedures, for parts replacement instruc-

tions.

Under no circumstances are field repairs to be attempted

on Printed Circuit Boards or other Subassemblies of this

unit. Evidence of unauthorized repairs will void the fac-

tory warranty.

NOTE

The troubleshooting contained in this manual is

for the Merlin 3000 Power Supply only. Trouble-

shooting other parts of the system is covered in the

separate manuals for that product.

4.02 Periodic Inspection &

Procedures

NOTE

Refer to Appendix XV for a recommended mainte-

nance schedule for water cooled plasma cutting

systems.

This subsection describes inspection procedures which

should be performed at periodic intervals as required.

A. Fan Motor and Pump Lubrication

The fan motor and pump in the power supply should

be oiled twice per year or once for each 100 hours of

operation. To oil the motor, remove one side panel

and add two or three drops of 20 SAE oil to the front

and rear oil holes on the motor.

NOTE

Some units may utilize a sealed motor design which

does not require lubrication.

B. Routine Maintenance

The only other routine maintenance required for the

power supply is a thorough cleaning and inspection,

with the frequency depending on the usage and the

operating environment.

To clean the unit, first make sure that the power is

disconnected. Remove the side panels and blow out

any accumulated dirt and dust with compressed air

especially from the radiator. The unit should also be

wiped clean. If necessary, solvents that are recom-

mended for cleaning electrical apparatus may be used.

While the side panels are off, inspect the wiring in the

unit. Look for any frayed wires or loose connections

that should be corrected.

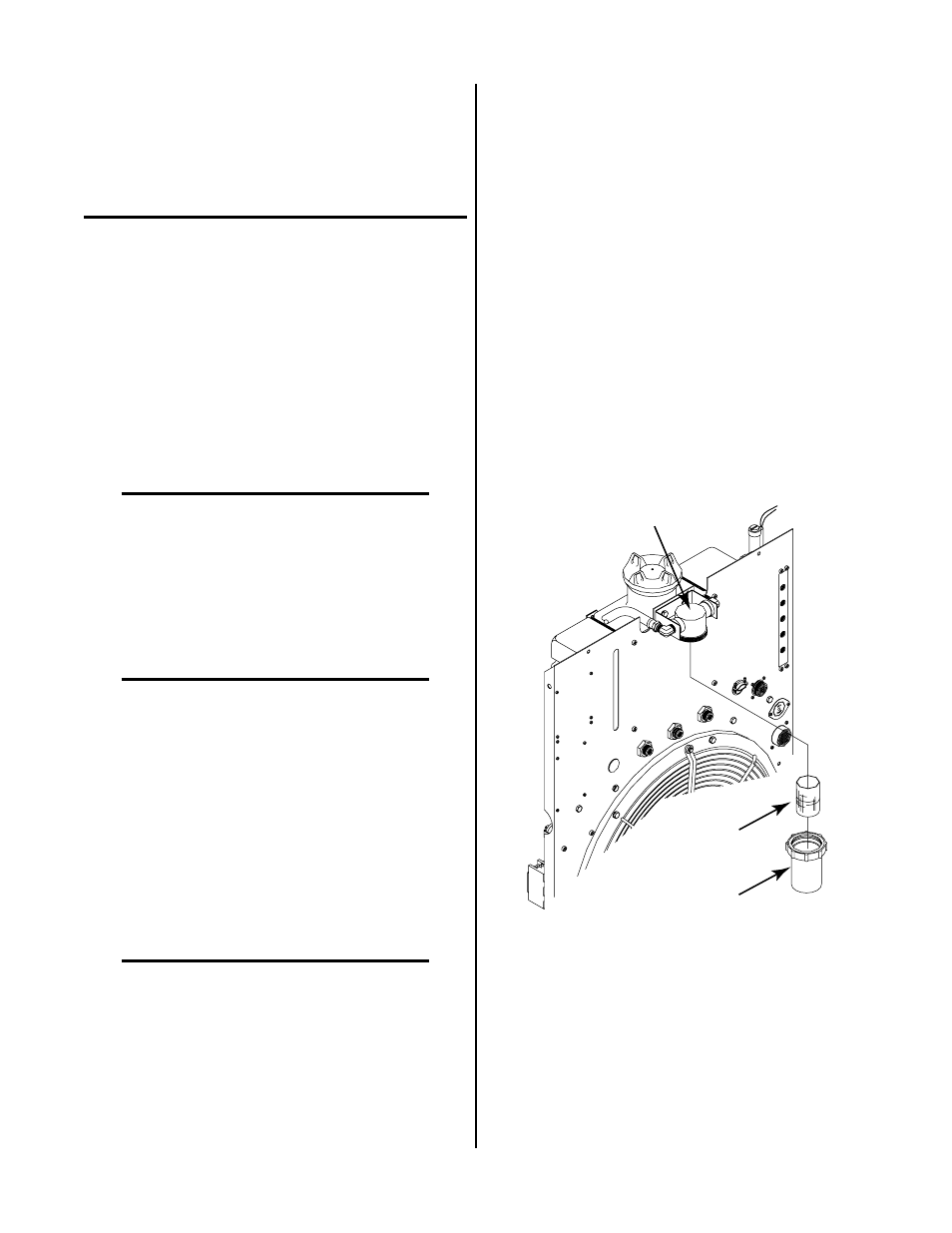

C. Coolant Filter Assembly (Rear Panel)

The rear panel filter screen should be cleaned peri-

odically. Remove the filter screen by unscrewing the

filter holder from the Coolant Filter Assembly. Clean

the filter screen by rinsing with hot soapy water. Re-

move soap residue by rinsing with clean hot water.

Be sure that all the soap has been removed and the

screen is dry of water before re-installing in the Cool-

ant Filter Assembly.

Coolant Filter Assembly

Filter Screen

Filter Holder

A-01018

Figure 4-1 Coolant Filter Assembly (Rear Panel)

D. Internal Filter Assembly

The internal filter screen should be cleaned periodi-

cally. To gain access to the Internal Filter Assembly

remove the Left Side Panel (viewed from the front of

unit) of the Power Supply. Remove the filter screen

by unscrewing the filter holder from the Internal Fil-

ter Assembly. Clean the filter screen by rinsing with