TracRac SKU# 00-25850 User Manual

Page 3

6 Contractor Rac Pro

INSTRUCTION MANUAL

TracRac Inc. 994 Jefferson Street, Fall River, MA 02721-4893 • 800-501-1587

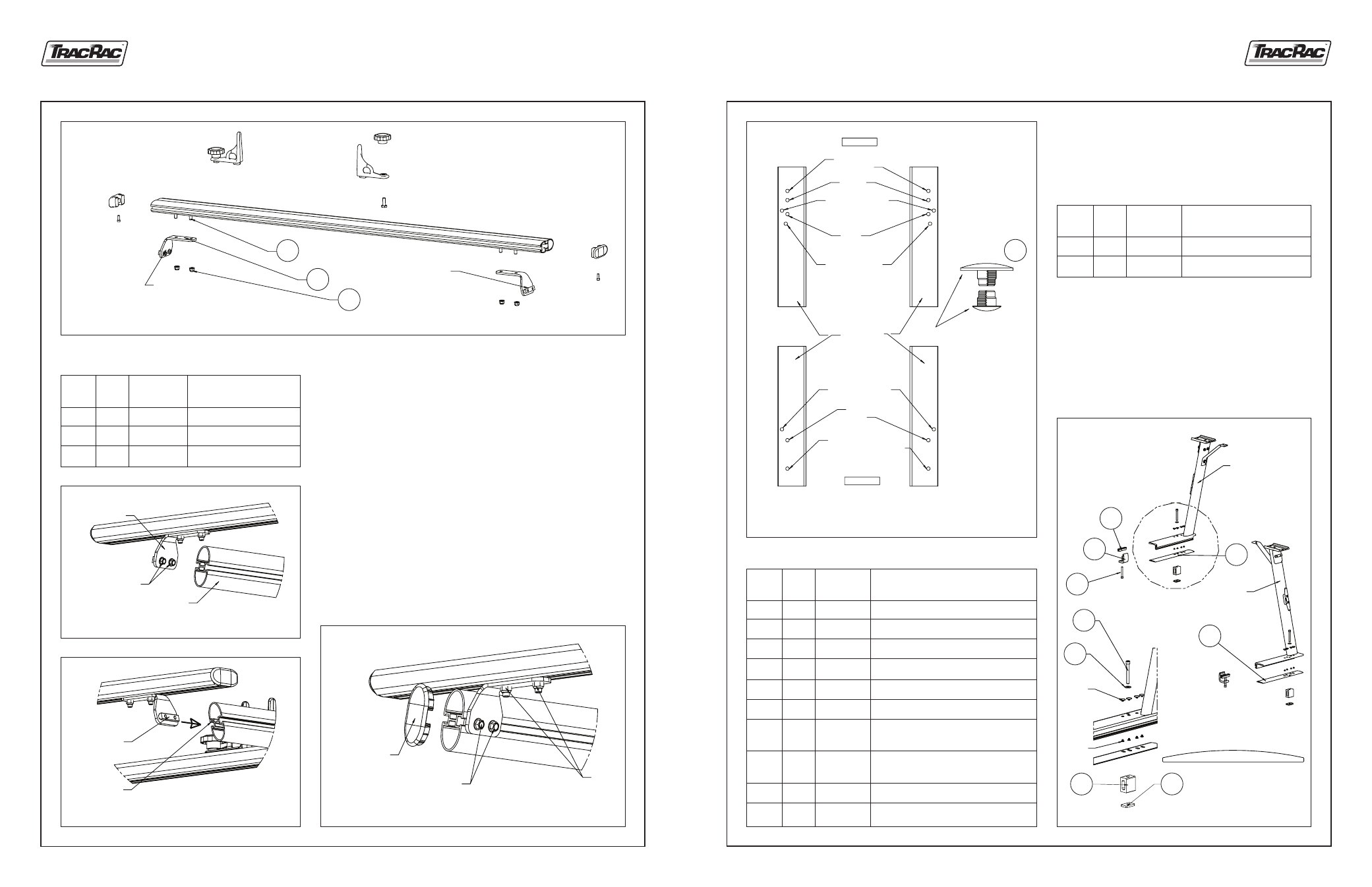

10. Built forward crossbar assembly by following the steps of the

standard crossbar assembly except slide 4 bolts (item 1) into

bottom groove of the crossbar (2 per side). Attach the end caps.

Loosely attach the bracket assemblies to the crossbar using lock

nuts and 15mm socket.

11. Loosen two bolts (13mm socket) on the forward bracket assemblies.

Slide the nut bar into the cantilever groove on each side.

12A. Align the bracket with the end of the front cantilever.

12B. Tighten two bolts using 13mm socket (Torque 90-110 lbs).

12C. Tighten two nuts using 15mm socket (Torque 220-240 lbs) on each side.

12D. Press the end caps into the front and rear cantilevers.

Make sure that all bolts and nuts are tightened up.

Assembly is completed.

Figure 10. Forward Crossbar assembly.

Item

No.

1

2

3

Qty.

4

2

4

Table 6. Forward Crossbar assembly parts

Description

T-Bolt, M10-1.5X25

Bracket, Forward

Lock Nut #10-1.5

Part No.

HD-80218

01-25051

HD-23179

Figure 11A. Crossbar installation. DETAIL A.

Figure 11B. Crossbar installation. DETAIL B.

Figure 12. End cap installation.

BRACKET

ASSMEBLY

1

BRACKET

ASSMEBLY

2

3

FORWARD

BRACKET

ASSMEBLY

TWO BOLTS

FRONT

CANTILEVER

NUT

BAR

CANTILEVER

GROOVE

TWO

BOLTS

TWO

NUTS

END CAP

P/N PI-23326

Contractor Rac Pro

INSTRUCTION MANUAL

3

TracRac Inc. 994 Jefferson Street, Fall River, MA 02721-4893 • 800-501-1587

3. After selecting the correct hole pattern for your truck

(using Figure 3), plug up all other holes using the black

plastic rivets. Large rivet–on the top, small rivet–on

the bottom (Figure 4).

Figure 3. Footprint for base of uprights.

Item

No.

1

2

Qty.

15

15

Table 3. Plastic Rivets

Description

Rivet, Small, Ratchet, Black

Rivet, Large, Ratchet, Black

Part No.

PI-23328

PI-23329

4. Attach rubber block assembly and rubber shim to uprights

using socket head cap bolt, washer, rubber shim, rubber

block and brass square pocket nut, see Figure 4. Complete

all four upright assemblies. Do not attach the L-Rail

clamps (items 1,9 and 10), see Figure 5. NOTE: Match

the hole patterns in the rubber shims to the correct

upright. Flat surface of rubber shim must face down.

Figure 4. Front upright

assembly.

Item

No.

1

2

3

4

5

6

7

8

9

10

Qty.

4

2

2

2

1

1

1

1

2

2

Table 4. Upright Assembly Parts

Description

Bolt Socket Head Cap, 3/8-16x3.00”

3/8 Washer, THIN

Rubber Block

Sq Pocket Nut, Brass

Rubber Shim, Front LH

Rubber Shim, Front RH

Rubber Shim, Rear LH

(Not Shown)

Rubber Shim, Rear RH

(Not Shown)

Clamp, L-Rail

U-Channel 3” Long

Part No.

HD-11011

HD-80078

RX-11031

01-2100N

FX-23269

FX-23270

FX-23271

FX-23272

01-23222

01-22911

FRONT

DODGE

FORD F150

CHEVY

TOYOTA TUNDRA

RH

GMC

FORD F250/350

UPRIGHT BASE

(VERTICAL OVAL TUBE

NOT SHOWN)

TOYOTA TUNDRA

DODGE

FORD F150/250/350

CHEVY

GMC

RH

REAR

LH

LH

SNAP IN THEM TOGETHER

UPRIGHT BASE BETWEEN

THEM NOT SHOWN

10

2

FRONT

UPRIGHT

LH

FRONT

UPRIGHT

RH

RUBBER SHIM

FLAT FACES DOWN

SMALL

RIVET

LARGE

RIVET

5

6

9

1

2

1

3

4