Toshiba MMU-AP0121MH User Manual

Page 86

86

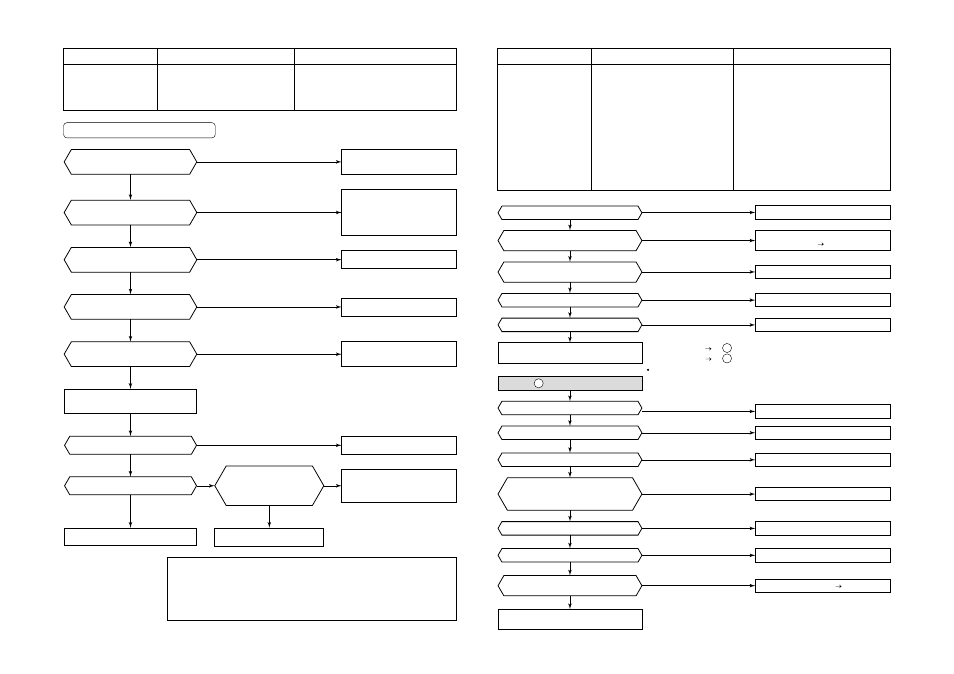

Check code name

[P19]

Check code name

4-way valve operation error

Cause of operation

1. 4-way valve error

2. TS1 sensor/TE1 sensor error

3. Pd sensor/Ps sensor error

4. TE sensor/TL sensor misconnection

Auxiliary code : Detected outdoor unit No.

Replace sensor.

Replace sensor.

Does not discharge

refrigerant gas bypass to

suction side through

4-way valve?

*

1

Check 4-way valve.

If an error did not occur

in test operation,

restart the operation.

Does 4-way valve operate?

Is the flow selector unit normal?

4-way valve error

Is 4-way valve coil

connector connected?

Are TS1, TE1, Pd, Ps sensor

connectors connected?

Are characteristics of resistance value

of TS1 and TE1 sensors normal?

Are output voltage characteristics

of Pd and Ps sensors normal?

Are connection and installation

of TE1 and TL sensors correct?

Reset the power supply and

start heating test operation.

Correct connector connection.

(4-way valve coil: CN317)

Correct connection

and installation.

*

1 Check TS and TE temperature of the outdoor unit which compressors is operated.

(I/F) SW01=[1], SW02=[6], SW03=[2]

®

TS sensor temperature

SW01=[1], SW02=[7], SW03=[2]

®

TE sensor temperature

≤

20˚C except summer season (Outside temp 20˚C or lower)

TS sensor: Normal if TS

≤

40˚C except summer season (Outside temp 20˚C or lower)

Correct connector connection.

TS1 sensor: CN504

TE1 sensor: CN505

Pd sensor: CN501

Ps sensor: CN500

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Replace the FS unit.

NO

NO

YES

Check code name

[P20]

Check code name

High-pressure protective operation

Cause of operation

1. Pd sensor error

2. Service valve closed.

3. Indoor/outdoor fan error

4. Indoor/outdoor PMV clogging

5. Indoor/outdoor heat exchanger clogging

6. SV2 circuit error

7. SV4 circuit error

8. SV5 circuit error

9. Outdoor I/F P.C. board error

10. Operation error of check valve of main

discharge pipe

11. Refrigerant overcharge

Reset power supply, and start a test

operation corresponded to the season.

Open service valves fully.

Check parts.

Failure

Replace

1. Pressure by pressure gauge (Check joint)

2. Pressure display on 7-segment display

3. Output voltage of I/F P.C. board

If 1 and 2, 3 are different, an error of pressure sensor is considered.

If 2 and 3 are different, check I/F P.C. board.

Is there a cause to interfere operation

of heat exchanger of outdoor unit?

1. Heat exchanger clogging

2. Air short circuit

Refrigerant overcharge, clogging,

pipe breakage, abnormal overload condition

(Connector connection, fan IPDU, fan motor, wiring)

YES

YES

YES

YES

Normal

Normal

Normal

YES

NO

NO

YES

YES

YES

YES

NO

NO

Correct piping.

Correct faulty parts.

Correct faulty parts.

(Connector connection wiring, coil mounting, valve clogging, etc)

NO

Correct faulty position.

(Coil error, clogging, disconnection of cable, etc.)

NO

Repair SV2 circuit.

(Coil error, clogging, disconnection of cable, etc.)

NO

Repair SV4 circuit.

NO

Repair check valve.

Replace

Abnormal

Replace defective parts.

Abnormal

Repair the flow selector unit.

Eliminate the interfered causes.

Abnormal

NO

All cooling operation

To B

All heating operation

To C

Is SV2 circuit normal?

Is SV4 circuit normal?

Is outdoor PMV1, 2 normal?

Is there no fan crack or coming-off?

B All cooling operation

Are service valves fully opened?

Check operation of PMV3 SV12.

Is the flow selector unit normal?

Does check valve of main

discharge pipe normally operate?

Does cooling outdoor fan normally operate?

Are characteristics of

high-pressure sensor normal?

Check mispiping of discharge gas/

suction gas main pipes.