Instructions for reversing air flow (cont'd), Suspending or mounting the furnace, Suspending the furnace – Thomas & Betts EEDU User Manual

Page 6: Mounting the furnace

Form 421, Page 6

6. Instructions for Reversing Air

Flow (cont'd)

3. All Models - Relocate the limit control.

a) At the discharge end on the same side of the heat exchanger, mea-

sure down 4-1/2" and in 1-11/16". Using that point as the center,

punch a 2-1/4" diameter hole in the side panel.

NOTE: It may be necessary to move cable connections. Re-insert

screws to plug all holes in the side panel. After the limit control is

installed, the cable connections may be re-attached using field-sup-

plied sheet metal screws.

b) With the limit control on the heat exchanger side of the bracket,

slide the limit control/bracket assembly into the hole. Attach the

bracket with two sheet metal screws.

c) Cover all of the original factory-made limit control holes with a

field-supplied sheet metal plate. Do not leave any open holes in the

side panel or the heat exchanger bottom.

4. The furnace is now ready for installation with the air flow from front

to rear (gas valve side).

7. Suspending or Mounting the

Furnace

Before installing the furnace, check the supporting structure to be used

to verify that it has sufficient load-carrying capacity to support the weight

of the unit.

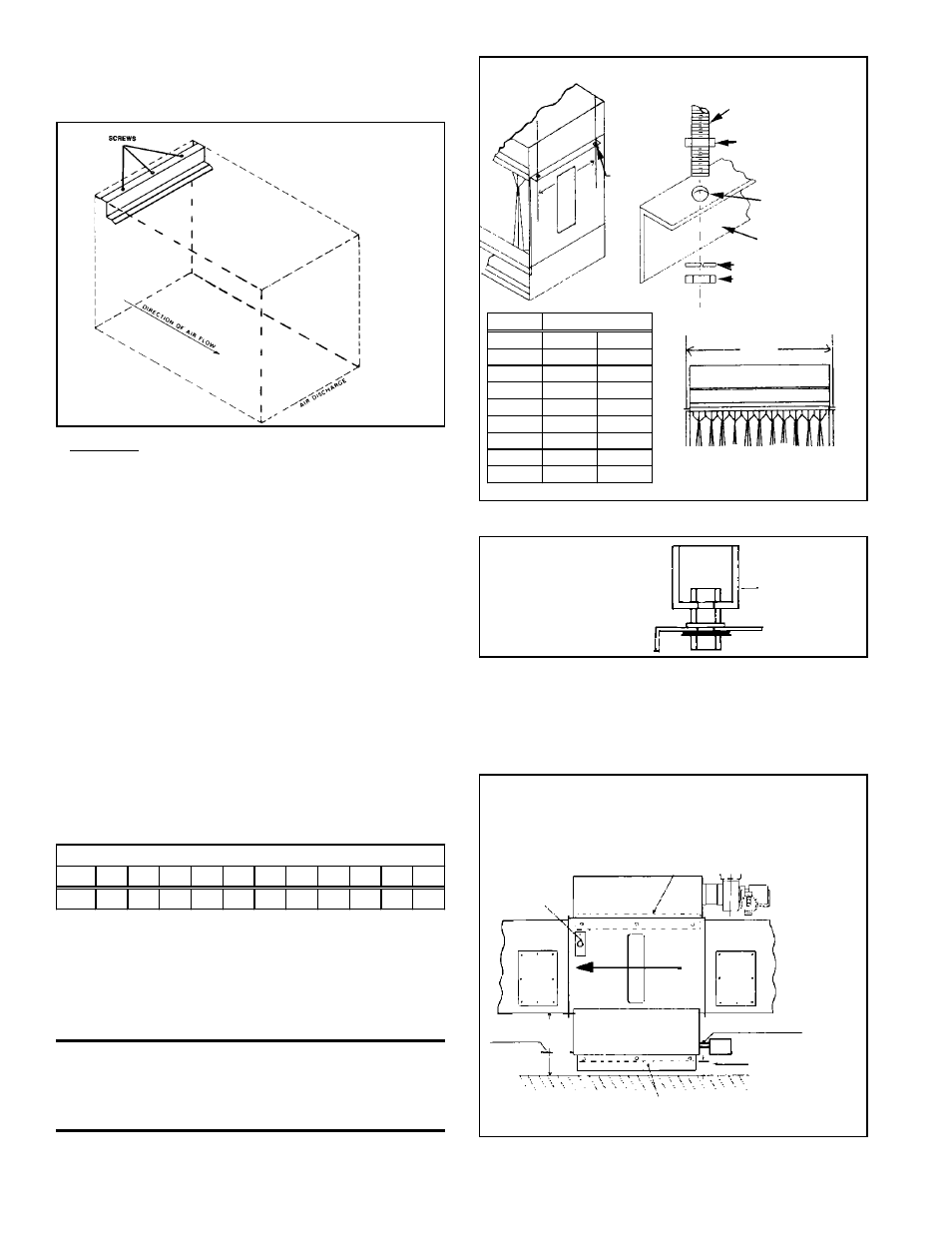

Suspending the Furnace

The furnace is provided with four 15/32" diameter holes to provide

four-point suspension. To suspend the unit, cut lengths of 7/16"-16

threaded rod to provide unit height. See Figure 4A for details. NOTE:

A hanger adapter kit Option CK3 is available to facilitate suspension.

See Figure 4B.

WARNING: Units must be level for proper

operation. Do not place or add additional weight

to the suspended furnace. See Hazard Levels,

page 2.

Figure 4B - Option

CK3 Hanger Kit (P/N

57959) with four

threaded sockets

Mounting the Furnace

Change position of the hanger bracket as shown in Figure 5. When the

furnace is mounted on combustible material, a minimum clearance of

12" is required.

Figure 5 - Base Mounted Furnace

Figure 3C - Model

HEEDU has only a

top rear heat

exchanger baffle.

Net Weight

S ize

75 100 125 140 170 200 225 250 300 350 400

Lbs

104 104 126 128 150 172 194 216 262 306 328

Figure 4A - Suspending a Single Furnace

Size

"A"

75-100

14-5/8"

371mm

125-140

17-3/8"

371mm

170

20-1/8"

371mm

200

22-7/8"

371mm

225

25-5/8"

371mm

250

28-3/8"

371mm

300

33-7/8"

860mm

350

39-3/8"

1000mm

400

44-7/8"

1140mm

16"

15/32"

(12mm)

Diameter

Hole

7/16" Diameter

Threaded Rod

Nut for 7/16" Rod

15/32" (12mm)

Diameter Hole

Hanger

Nut for 7/16" Rod

Split Ring Lockwasher

(406

mm)

A

Centerline of hangers

Free-turning

threaded

socket

(1" pipe)

As shipped location of hanger

support angle

Limit

Control

Access

Panel

Access

Panel

10"

(254

mm)

Combustion

Air Inlet

6" (152mm)

minimum

clearance

6"

Hanger Support Angle

Combustion Air Inlet

Keep clean and maintain 29"

(737mm) clearance for burner

rack service

12" (305mm)

Airflow

Direction