Troubleshooting (cont'd), For service or repair, follow these steps in order, First – Thomas & Betts EEDU User Manual

Page 24: Second, Third

Form 421, Page 24

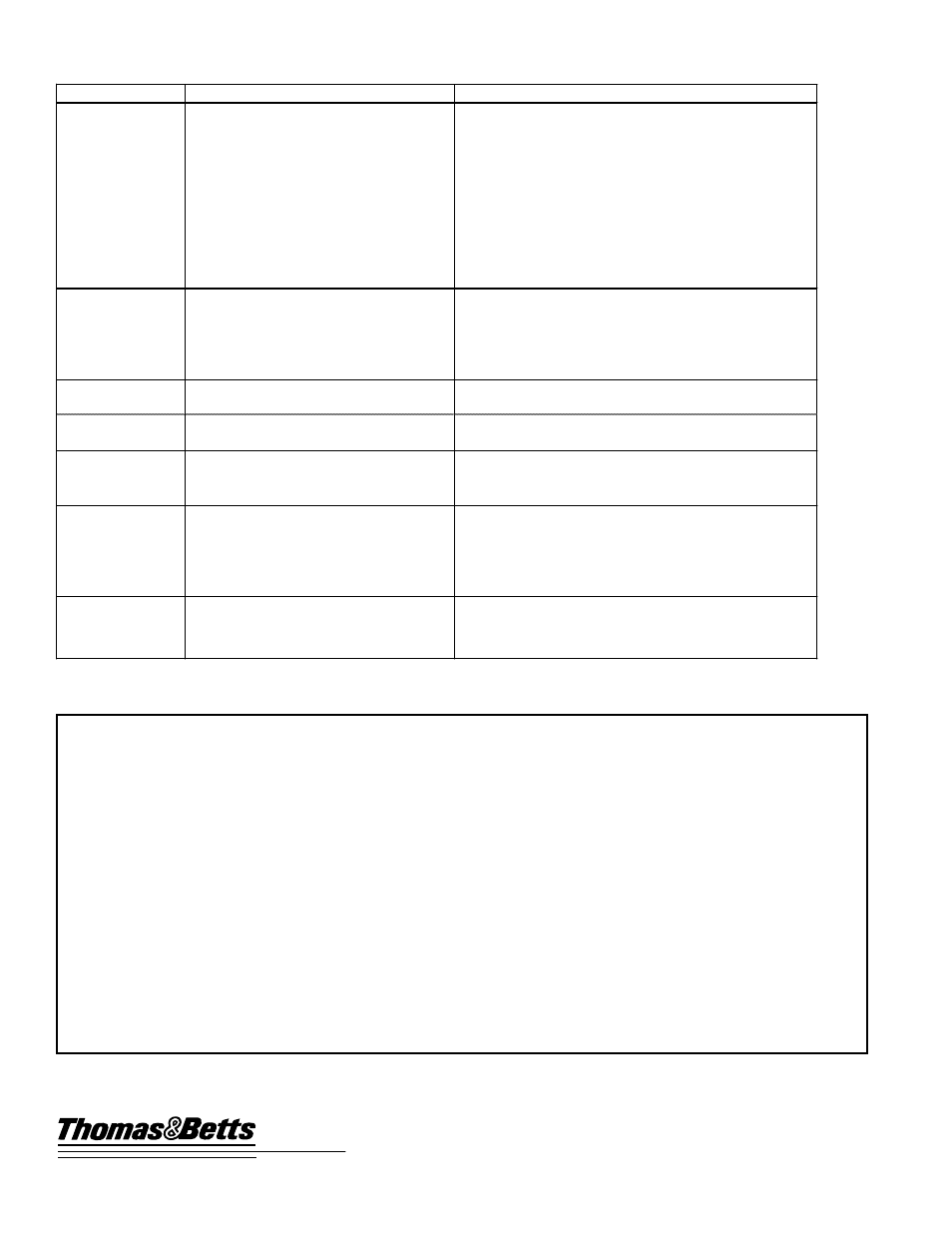

32. Troubleshooting (cont'd)

FIRST:

Contact the installer.

Name

_______________________________________________________________________________________

Address ________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

Phone

________________________________________________________________________________________

SECOND:

Contact the nearest distributor (See telephone Yellow Pages.)

THIRD:

Contact:

REZNOR

®

, Thomas & Betts Corporation

150 McKinley Avenue

Mercer, PA 16137

Phone: (724) 662-4400

Model No. _______________________________________

Unit Serial No. ___________________________________

Date of Installation ________________________________

©2000 Thomas & Betts Corporation, All rights reserved.

Printed in the U.S.A.

MANUFACTURER OF GAS, OIL, ELECTRIC HEATING AND VENTILATING SYSTEMS

Trademark Note: Reznor

®

is registered in the United States and other countries.

3/00 YL Form 421-A.5

FOR SERVICE OR REPAIR, FOLLOW THESE STEPS IN ORDER:

TROUBLE (cont'd)

PROBABLE CAUS E (cont'd)

REMEDY (cont'd)

Pilot lights, main 3. Ignition control does not power main valve. 3.

valve will not open

a) Loose wire connections.

a) Check and tighten all wiring connections.

(cont'd)

b) Flame sensor grounded. (Pilot lights - spark

continues)

b)Be certain flame sensor lead is not grounded or insulation or

ceramic is not cracked. Replace as required.

c) Gas pressure incorrect.

c) Set supply pressure at 5" w.c. to 14" w.c. for natural gas and

11" w.c. to 14" w.c. for propane gas.

d) Cracked ceramic at sensor.

d) Replace sensor.

e) Faulty ignition controller.

e) If all checks indicate no other cause, replace ignition

controller. Do not attempt to repair ignition controller; it has no

field replaceable components.

No heat (Heater

1. Dirty Filters

1. Clean or replace filters.

Operating)

2. Incorrect manifold pressure or orifices.

2. Check manifold pressure (See Paragraph 9).

3. Cycling on limit control.

3.Check air throughput (See Paragraph 15).

4. Improper thermostat location or adjustment. 4. See thermostat manufacturer's instructions.

5. Belt slipping on blower.

5. Adjust belt tension.

Cold air delivered

1. Fan control improperly located or adjusted. 1. Relocate or adjust fan control (See Paragraph 19).

On S tart-up

2. Defective fan control.

2. Replace fan control.

During Operation 3. Blower set for too low temprrature rise.

3. Slow down blower or increase static pressure..

4. Incorrect manifold pressure.

4. Check manifold line pressure (See Paragraph 9).

Motor will not run

1. Circuit open.

1. Check wiring and connections.

2. Fan control inoperative.

2. Replace fan control.

3. Defective motor or capacitor.

3. Replace motor or capacitor.

Motor turns on and 1. Fan control improperly located or adjusted. 1. Relocate or adjust fan control (See Paragraph 19).

off while burner is

2. Defective fan control.

2. Replace fan control.

operating (S ee

"Motor... " below)

3. M otor overload device cycling on and off.

3. Check motor load against motor rating plate. Replace motor

if needed.

4. 3 phase motor rotating in opposite

4. Interchange 2 legs on supply connections.

Blower motor cuts 1. Improper motor pulley and/or adjustment.

1. See instructions on air throughput.

out on overload

2. Improper static pressure in the duct system. 2. Adjust duct system dampers.

3. Low voltage.

3. Check power supply.