Application considerations, Features and benefits, Two-stage compressor widens the application range – Trane CVGF User Manual

Page 9

9

CTV-PRC001-GB

Two-Stage Compressor

Widens the Application

Range

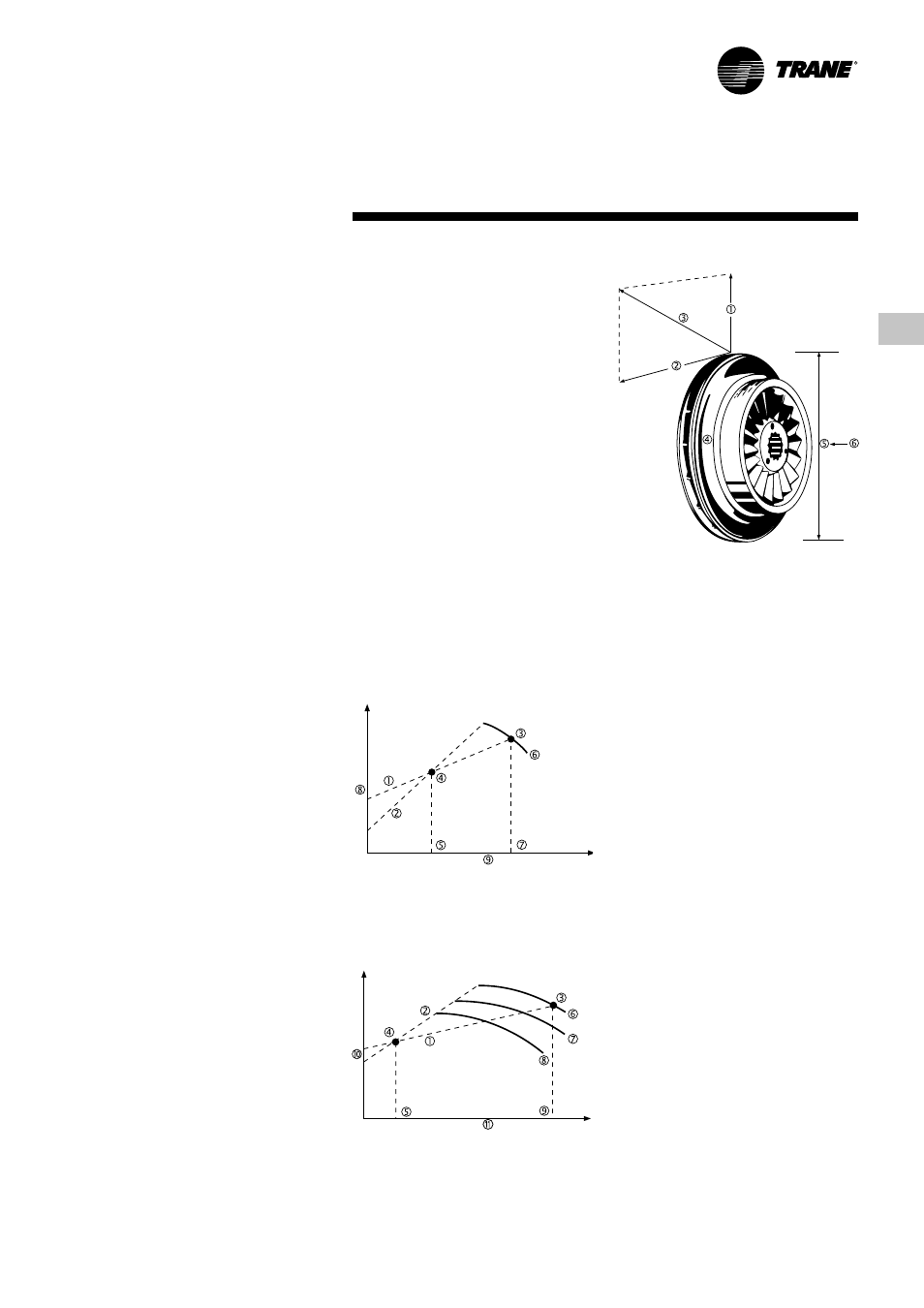

Why Centrifugal Compressors Surge

Centrifugal compressors produce their

pressure differential (head) by

converting the kinetic energy of the gas

leaving the impeller into static

pressure. The velocity of this gas is the

result of two components:

• The radial velocity component V

r

,

which is directly proportional to the

refrigerant gas flow Q.

• The tangential velocity component V

t

,

which is a function of both impeller

diameter D and the rotational speed

rpm.

The length of the resultant vector V is

proportional to the kinetic energy

available for conversion to static

pressure in the volute. Consequently,

for a given compressor, V

t

is fixed and

V

r

varies with the cooling load. With the

chiller unloading, the pressure

differential between evaporator and

condenser decreases. The compressor

matches the new load and the lower

“head” by closing the inlet guide

vanes.

This reduces the gas flow it draws in

and modifies its direction. Component

Vr decreases accordingly, the vector

diagram shifts and at some point, the

balance of forces breaks down.

As pressurized gas rushes backwards

through the impeller, the pressure in

the gas passages falls, allowing the

compressor to restore the balance of

forces. If the process repeats itself, the

compressor is said to surge.

1 - V

r

= f (Q)

2 - V

t

= f (D, RPM)

3 - V = Resultant

4 - RPM

5 - D

6 - Q

Two-Stage Compressors Surge Less

and Later

To produce the same head as a single-

stage compressor, two-stage machines

use two small diameter impellers.

Component V

t

is the same as on each

stage, though V

r

is the same as on a

single-stage compressor. This results in

a better balance of forces at low loads

and produces a machine with a wider

unloading capability.

In Trane centrifugal chillers, gas

prerotation vanes ahead of the

compression stage improve impeller

aerodynamic efficiency, resulting in

smoother unloading and reducing

power consumption.

The curves show that two-stage

compressors surge less and later than

single-stage machines. Intersection

point B, when the load line meets the

surge area, corresponds to a higher

part load for the single-stage

compressor than would be the case

with a two-stage compressor. Two

stage machines, therefore, have a

wider range of applications.

Typical single-stage compressor

performance curve

1 - Load Line

2 - Surge Line

3 - A

4 - B

5 - 40%

6 - 90° Vanes

7 - 100%

8 - Compressor Head

9 - Refrigerant Gas Flow

Typical two-stage compressor

performance curve

1 - Load Line

2 - Surge Line

3 - A

4 - B

5 - 20%

6 - 90°

7 - 80°

8 - 70° Vanes

9 - 100%

10 - Compressor Head

11 - Refrigerant Gas Flow

Features and

Benefits