Controls, Jobsite connections, Supply and motor lead wiring and connections – Trane CVGF User Manual

Page 13: Shipment and assembly

1 3

CTV-PRC001-GB

Jobsite

Connections

Supply and Motor Lead

Wiring and Connections

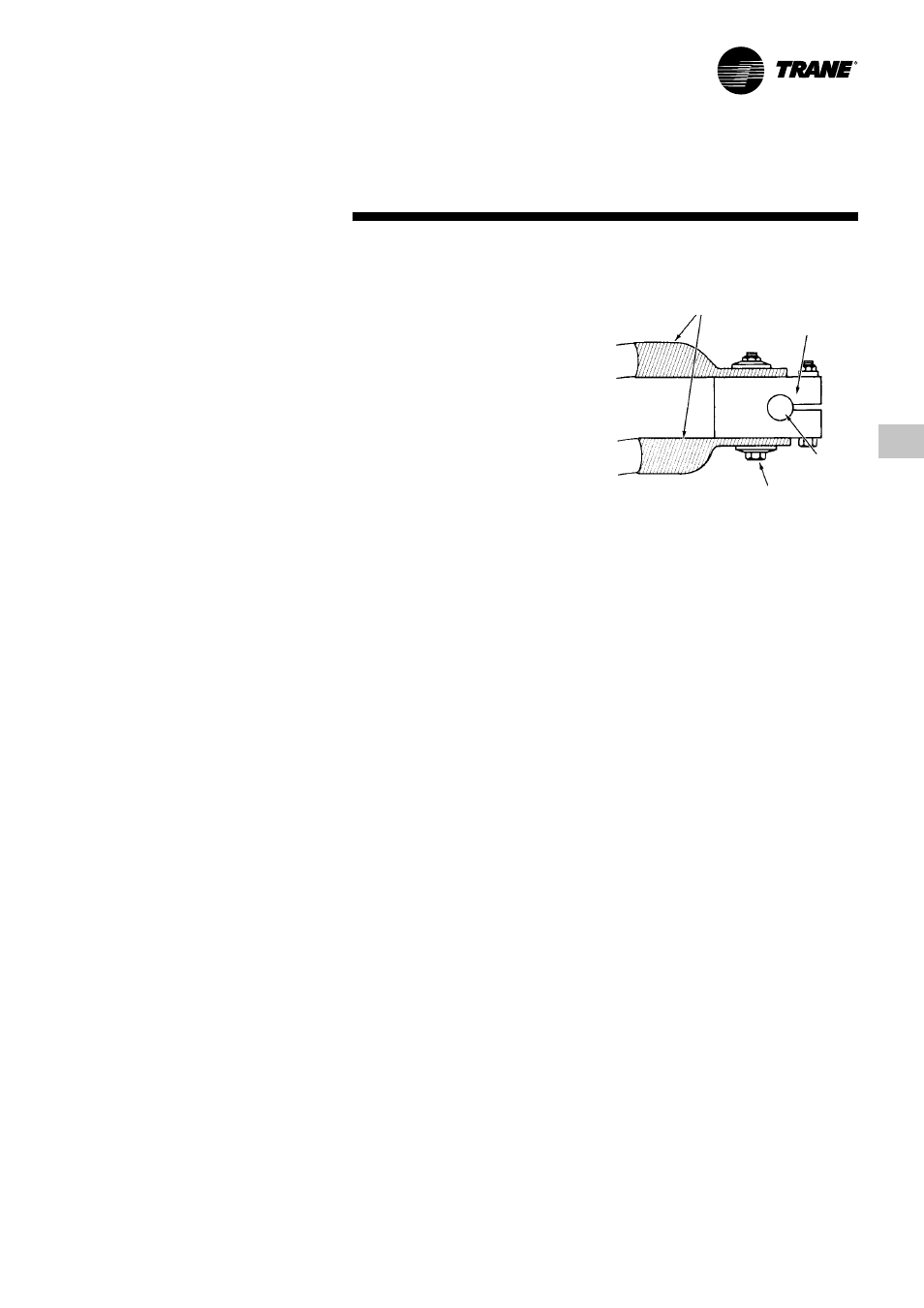

Copper conductors only should be

connected to the compressor motor

due to the possibility of galvanic

corrosion as a result of moisture if

aluminum conductors are used.

Copper conductors are recommended

for supply leads in the starter panel.

Suggested starter panel line and load

side lug sizes (when lugs are provided)

are noted in the starter submittals.

These submitted lug sizes should be

carefully reviewed for compatibility

with conductor sizes specified by the

electrical engineer or contractor. If they

are not compatible, the electrical

engineer or contractor should specify

the required lug sizes for the particular

application. Ground lugs are provided

in the motor terminal box and starter

panel. The motor terminals are

supplied with connection pads which

will accommodate bus bars or

standard terminal lugs (crimp type

recommended). Terminal lugs are field-

supplied. These connection pads

provide additional surface area to

minimize improper electrical

connections. Also, a

3

/

8

-inch bolt is

provided on all connection pads for

mounting the lugs. Figure J-1 illustrates

the connection between the motor

connection pads and the terminal lugs.

Figure J-1 — Electric Connections

Shipment and Assembly

All style hermetic centrifugal units ship

as a factory assembled, factory tested

package, ready to rig into place on

factory supplied isolation pads.

Terminal Lugs (Field-Supplied)

Connection Pad

3/8” Bolt

Motor

Terminal

Stud