Product instruction sheet, Troubleshooting chart – Omega FCLTX-100 User Manual

Page 5

PRODUCT INSTRUCTION SHEET

10.1 GENERAL MAINTENANCE. Service the sensor regularly

(weekly is suggested)

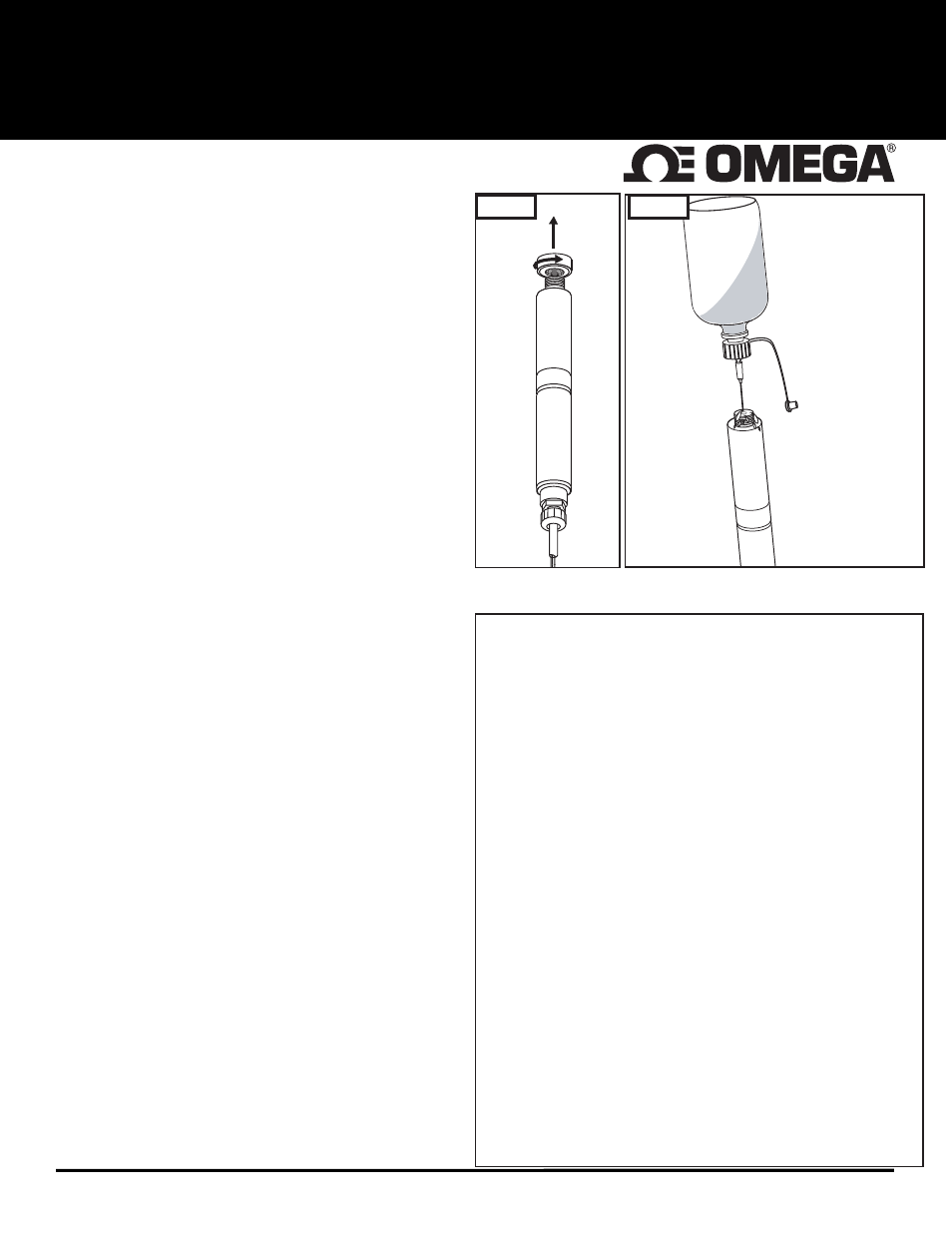

10.2 MEMBRANE CAP REPLACEMENT. If membrane replace-

ment is required, a new cap with preinstalled membrane must

be used. Order FCLA-2016 replacement membrane cap and

FCLA-2015 refill solution. To change membrane cap (do the

following over a sink or washbasin):

a) turn sensor upside down with cap facing upward

b) rotate cap counter-clockwise to remove (see FIG 10).

c) fill sensor body with electrolyte using needle and bottle of

refill solution (see FIG. 11)

d) install a new membrane cap by threading cap onto sensor

rotating cap clockwise (opposite of FIG 10)

10.3 MEMBRANE CAP/SENSOR CLEANING. Rinse cap with

water only. If cap does not clean, replace with new one.

SECTION 10.0

SENSOR MAINTENANCE/RECONDITIONING

SECTION 11.0

SENSOR TROUBLESHOOTING

11.1 CALIBRATION PROBLEMS

a) Sensor output

HIGHER than DPD test

1) Run in time too short

2) Membrane cap damaged

3) Interference from water

contaminants (see Specifications,

"Cross Sensitivity")

4) Cable short circuit or damage

5) pH value less than pH 5.5

b) Sensor output

LOWER than DPD test

1) Run in time too short

2) Deposits on Membrane cap

3) Flow rate too low

4) Air bubbles on membrane

5) Surfactants in water

6) pH value more than pH 8.0

7) No electrolyte in membrane cap

c) Sensor ouput is 4mA (zero ppm)

1) Run in time too short

2) Only bound chlorine present

3) Chlorine content below detection

limit

4) Sensor not wired correctly (See

SECTION 6.0 of this manual)

5)

Defective

sensor

d) Sensor output

UNSTABLE

1) Air bubbles on membrane

2)

Membrane

damage

3)

Non-sensor

problem

Symptom

Possible Cause

Solution/Remedy

The sensor

1) Run in time too short

1) See Sec 5.0 -CONDITIONING

cannot be

2) Membrane cap damaged

2) Replace cap - See Sec 8.0

calibrated-

3) Interference from contaminants

3) See SPECIFICATIONS

ouput is

4) DPD chemicals bad

4) Use new DPD kit

HIGHER than

5) pH value < pH 5.5

5) Increase pH (5.5-8.0)

DPD Test

See SPECIFICATIONS

6)Temperatue increased since cal

6) Match calibration temp.

The sensor

1) Run in time too short

1) See Sec 7.0 -CONDITIONING

cannot be

2) Deposits on membrane cap

2) Remove deposits or replace

calibrated-

cap if cleaning ineffective.

output is

3) Flow rate too low

3) increase fl ow - See

LOWER than

SPECIFICATIONS

DPD Test

4) Air bubbles on membrane

4) Remove and re-install sen

sor to remove bubbles.

5) Surfactants in water

5) Remove surfactants and

replace cap

6) pH > pH 8.0

6) Lower pH (5.5-8.0)

See SPECIFICATIONS

7) No electrolyte in cap

7) Add new electrolyte, run in

sensor and re-calibrate

8) Temperature decreased since cal 8) Increase temp to match cal

9) Organic chlorination agents

9) Use chlorinating agents

present in water

per DIN 19643

Sensor output

1) Only bound chlorine present

1) Check for Chloramine with

is 4mA (0 ppm)

NO FREE CHLORINE

appropriate DPD test.

Replace water/ Rechlorinate.

2) Run in time too short

2) See Sec 7.0 -CONDITIONING

3) Chlorine content below limit

3) Add chlorine and repeat

calibration

4) No electrolyte in cap

4) Refi ll electrolyte

5) Sensor electrical connection

5) See SECTION 6.0

wrong

Unstable output

1) Air bubbles on sensor membrane 1) Tap to remove bubbles

from sensor

2) Membrane damaged

2) Replace membrane, run in

sensor and recalibrate.

3) Non-sensor problem

3) check PLC or I/O device

TROUBLESHOOTING CHART

FIG. 10

INJECT UNTIL SOLUTION

LEAKS OUT OF FILL HOLE

FIG. 11

Parts covered by this product instruction sheet include: FCLTX-100 Series

M4679/0708 page 5 of 6