3) configure module via command line interface, 2) install standalone module and connect cables – Omnitron Systems Technology iConverter 2GXM User Manual

Page 2

NOTE: If mounting with a safety ground attachment, use the safety ground

screw at the rear of the unit.

b. Insert the SFP Fiber transceivers into the Port 1 and Port 2 SFP receptacles on the

2GXM.

NOTE: The release latch of the SFP Fiber transceiver must be in the closed

position before insertion.

c. Connect an appropriate multimode or single-mode fiber cable to the SFP fiber

ports of the installed module. It is important to ensure that the transmit (TX) is

attached to the receive side of the device at the other end and the receive (RX) is

attached to the transmit side. Single-fiber (SF) media converter models operate in

pairs. The TX wavelength must match the RX wavelength at the other end and the

RX wavelength must match the TX wavelength at the other end

NOTE: In order to support Remote OAM Management Mode, Port 1 of the

2GXM must be connected to the Port 1 on the 2GXM or link partner.

3) CONFIGURE MODULE VIA COMMAND LINE INTERFACE

To access the Command Line Interface (CLI), connect the 2GXM RS-232 Console

Port to the COM port of a computer equipped with terminal emulation software such

as HyperTerminal. The Console Port (DCE) is a mini DIN-6 female connector which

can be changed to a DB-9 connector with the included adapter. The 2GXM Console

Port is a standard asynchronous serial interface.

Start HyperTerminal and select the correct COM Port in the HyperTerminal “Connect

To:” window. Set the serial port to the following:

Bits Per Second

57,600

Stop Bits

1

Data Bits

8

Parity

NONE

Hardware Flow Control

NONE

Once connected, press <ENTER> to bring up a command line prompt on the attached

PC. A new 2GXM module does not have a password, and will skip the Password

Entry screen and go straight to the Management Options screen. If a password has

been set, the Password Entry screen will be displayed. Type the password and press

<ENTER>, the 2GXM will respond with the Management Options screen:

NOTE: The fiber optic ports operate in Full-Duplex mode in both Auto and Manual

negotiation modes.

SW3, SW4, SW5 - RESERVED

These DIP-switches are for factory use only and must always remain in the DOWN

position (factory default).

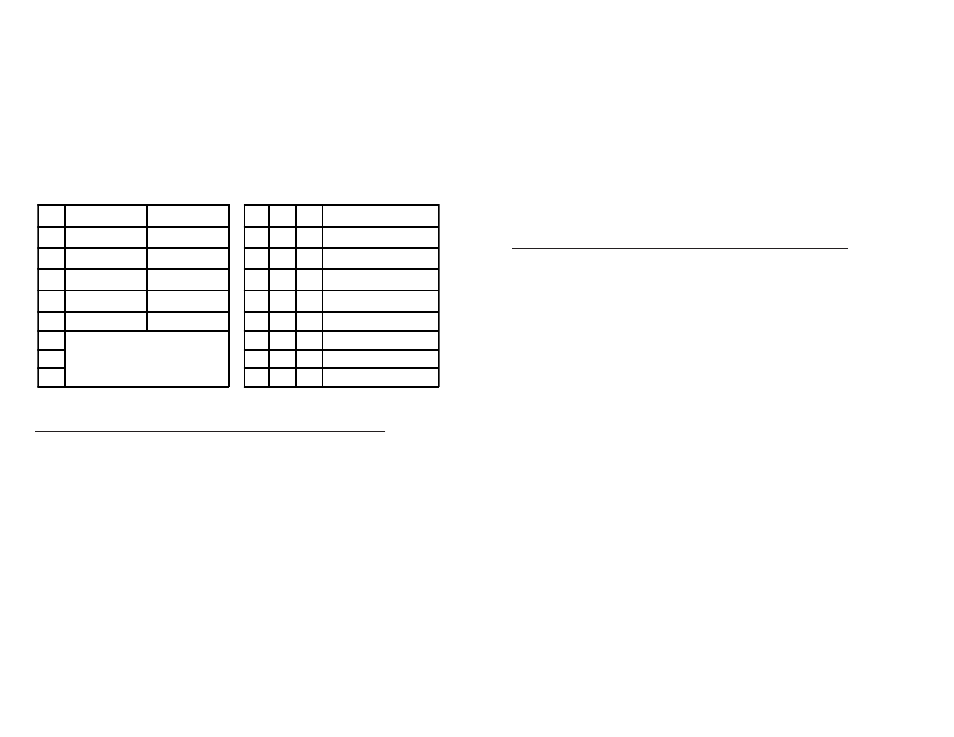

SW6, SW7, SW8 - LINK MODES

These three DIP-switches configure the link mode settings. The following table details

possible Link Mode DIP-switch configurations. For detailed information on the operation

of the different Link Modes, download the application note “

iConverter

Link Modes”

available on Omnitron’s web page:

http://www.omnitron-systems.com/downloads.php

Switch

Down

(Factory Default)

Up

SW6

SW7

SW8

Link Mode Selection

SW1 AN:

Fiber Port 1 Auto

Man:

Fiber Port 1 Manual

Down Down Down Link Segment (LS)

(Factory Default)

SW2 AN:

Fiber Port 2 Auto

Man:

Fiber Port 2 Manual

Up

Down Down Link Propagate (LP)

SW3

Reserved

Reserved

Down

Up

Down Remote Fault Detect + Link

Segment (RFD + LS)

SW4

Reserved

Reserved

Up

Up

Down Remote Fault Detect + Link

Propagate (RFD + LP)

SW5 Reserved

Reserved

Down Down

Up

Symmetrical Fault Detect (SFD)

SW6

See Link Mode Selection

Up

Down

Up

Illegal Setting

SW7

Down

Up

Up

Illegal Setting

SW8

Up

Up

Up

Illegal Setting

Figure B: DIP-Switches

2) INSTALL STANDALONE MODULE AND CONNECT CABLES

a. The 2GXM Network Interface Device (NID) is available in tabletop and wall-mounting

models. For wall-mounting, attach the NID to a wall, backboard or other flat surfaces.

For tabletop installations, place the unit on a flat level surface. Attach the rubber

feet to the bottom of the NID to prevent the unit from sliding. Make sure the unit is

placed in a safe, dry and secure location.

To power the unit using the AC/DC adapter, connect the AC/DC adapter to the AC

outlet. Then connect the barrel plug at the end of the wire on the AC/DC adapter to

the 2.5mm DC barrel connector (center-positive) on the chassis. Confirm that the

unit has powered up properly by checking the power status LED located on the

front of the unit.

To power the unit using a DC power source, prepare a power cable using a two-

conductor insulated wire (not supplied) with a 14 AWG gauge minimum. Cut the

power cable to the length required. Strip approximately 3/8 of an inch of insulation

from the power cable wires. Connect the power cables to the standalone unit by

fastening the stripped ends to the DC power connector.

Connect the power wires to the DC power source. The Power LED should indicate

the presence of power.

WARNING: Note the wire colors used in making the positive and negative

connections. Use the same color assignment for the connection at the DC

power source.