Troubleshooting guide – Omega 3200ST User Manual

Page 23

M-4271/0707, pg. 23 of 26

H.

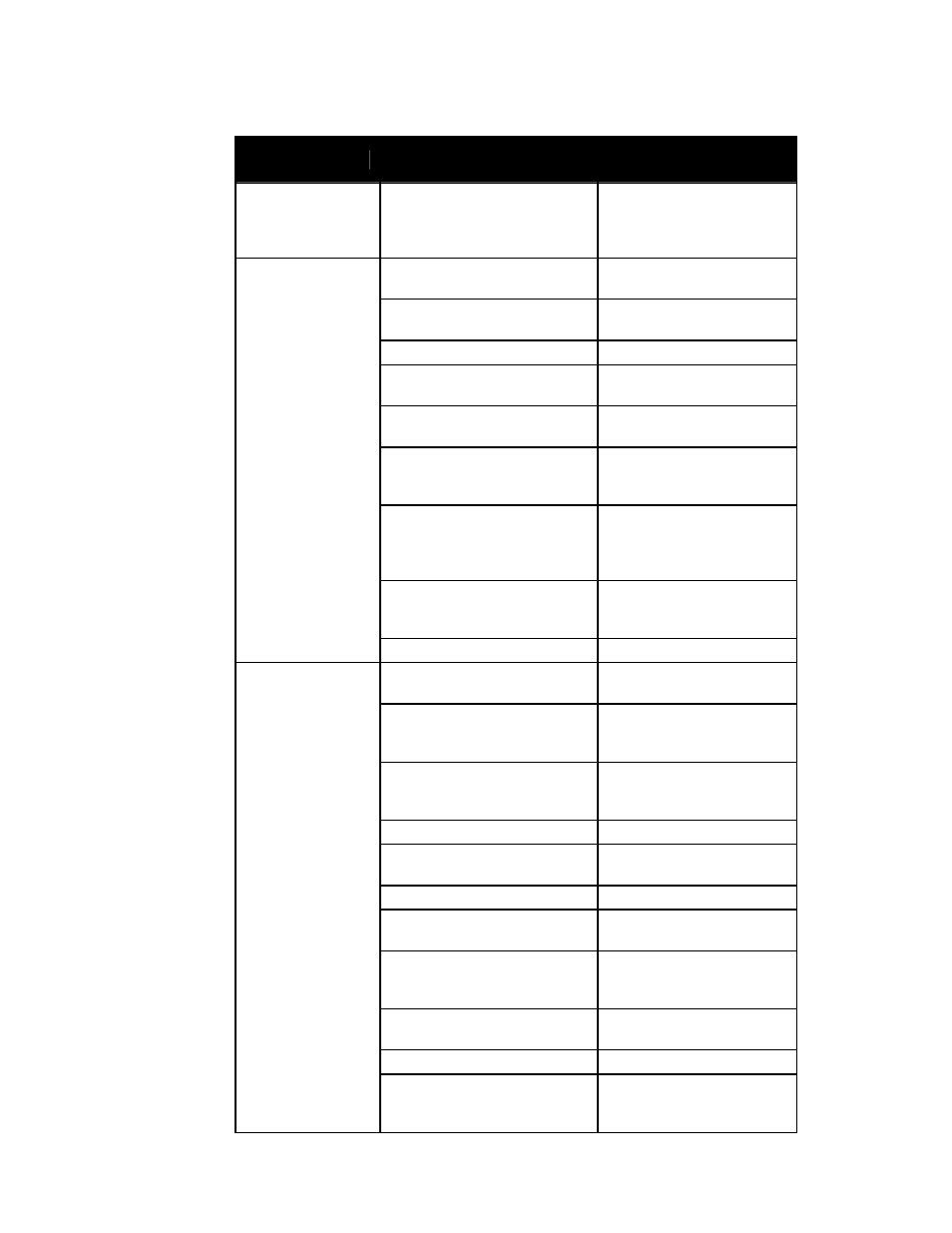

Troubleshooting Guide

Symptom

Possible Cause

Method of Correction

Clicking noise from

controller

Unit in error mode

Check there is sufficient

pressure and that the flow

path is not restricted or

blocked

Unit wired incorrectly

Check wiring is according to

Section B5

Loose connection

Check all connectors and

wiring

Damaged connector pins

Contact Omega Engineering

Blocked flow path

Check flow path for

obstructions.

Piping leak before sensor

Check all piping and

connections.

Insufficient power

Check the power supply

output and increase if

necessary

Output load resistance too low

Ensure the voltmeter or

data acquisition system or

display has an impedance of

greater than of 2.5kohm

Flow too low for the unit

Ensure that the flow being

measured is within the

capabilities of the unit

No response

Unit damaged or faulty

Contact Omega Engineering

Particles in flow path

Add filtration before the

sensor.

Flow path obscured

Remove any debris or

blockage in the flow path

eg. PTFE tape.

Unit calibrated for a different

gas

Check calibration certificate

and apply a “K” Factor to

readings if necessary.

Gas composition is variable

Contact Omega Engineering

Fittings have been changed

Replace the factory installed

fittings

Moisture in gas

Ensure gas is clean and dry

Insufficient warm-up period

Allow the unit to warm-up

for at least 5 minutes.

Zero drift

Verify the zero and adjust

as necessary as explained in

Section C

The gain potentiometer has

been adjusted

Contact Omega Engineering

Unit needs recalibration

Contact Omega Engineering

Inaccurate control

Flow too high for the unit

Ensure that the flow being

measured is within the

capabilities of the unit