Assembly – Orion SKYQUEST XX12 User Manual

Page 7

7

2. assembly

Now that you have unpacked the boxes and familiarized

yourself with all the parts in front of you, it’s time to begin

assembly.

assembly of the Dobsonian Base

Refer to Figure 5 during base assembly. The base need only

be assembled once, unless you disassemble it for long-term

storage. The assembly process takes about an hour and

requires, in addition to the supplied tools, a Phillips screw-

driver, and two adjustable crescent wrenches. (You can sub-

stitute a 10mm crescent wrench for one of the adjustable

crescent wrenches, or use a pair of pliers.) When tightening

screws, tighten them until firm, but be careful not to strip the

holes by over-tightening. If you use an electric screwdriver, do

final tightening with a standard screwdriver to avoid stripping.

1. With a Phillips screwdriver, screw the feet (Q) into the

underside of the ground baseplate (A) using the feet wood

screws provided. Insert the screws through the feet and

thread them into the predrilled starter holes.

2. Connect the side braces (N) to the side panels (C)

using three of the base assembly screws for each panel.

Connect each brace to the surface of the panel with the

SkyQuest IntelliScope label on it. The screws go through

the holes in the panels and thread into the starter holes in

the side braces. Use the 4mm hex key to firmly tighten the

screws.

3. Connect the front brace (B) to the two side panels (C)

with six of the base assembly screws. The screws go

through the holes in the side panels and thread into the

starter holes in the front brace. The side panels should

be oriented so the side braces are facing outward. The

front brace should be oriented so that the surface with the

metal insert (Figure 4) faces inwards. Do not completely

tighten the screws yet.

4. Connect the assembled structure to the top baseplate (D)

with the remaining eight base assembly screws in the pre-

drilled holes. The side of the top baseplate with the Ebony

Star laminate bearing surface ring should be facing down-

wards.

5. Firmly tighten the six base assembly screws installed in

step 2.

6. The azimuth encoder board (E) attaches to the under-

side of the top baseplate (D). The azimuth encoder board

can be found in the box with the optical tube. Between

the azimuth encoder board and top baseplate goes two

thick spacer washers (P) and one thin spacer washer (O).

These washers are critical in providing the proper spac-

ing for the assembled azimuth encoder. The two thick azi-

muth encoder spacer washers are included with the base,

but the thin azimuth encoder spacer washer is included

with the IntelliScope Object Locator kit. Insert an encod-

er wood screw through the slotted hole in the azimuth

encoder board so that the head of the screw is on the side

of the encoder board without the modular connector. Now,

place the two thick and one thin azimuth encoder spacer

washers on the screw (Figure 6).

C

M

B

L

K

D

F

E

A

J

H

N

N

R

O

Q

Q

I

P

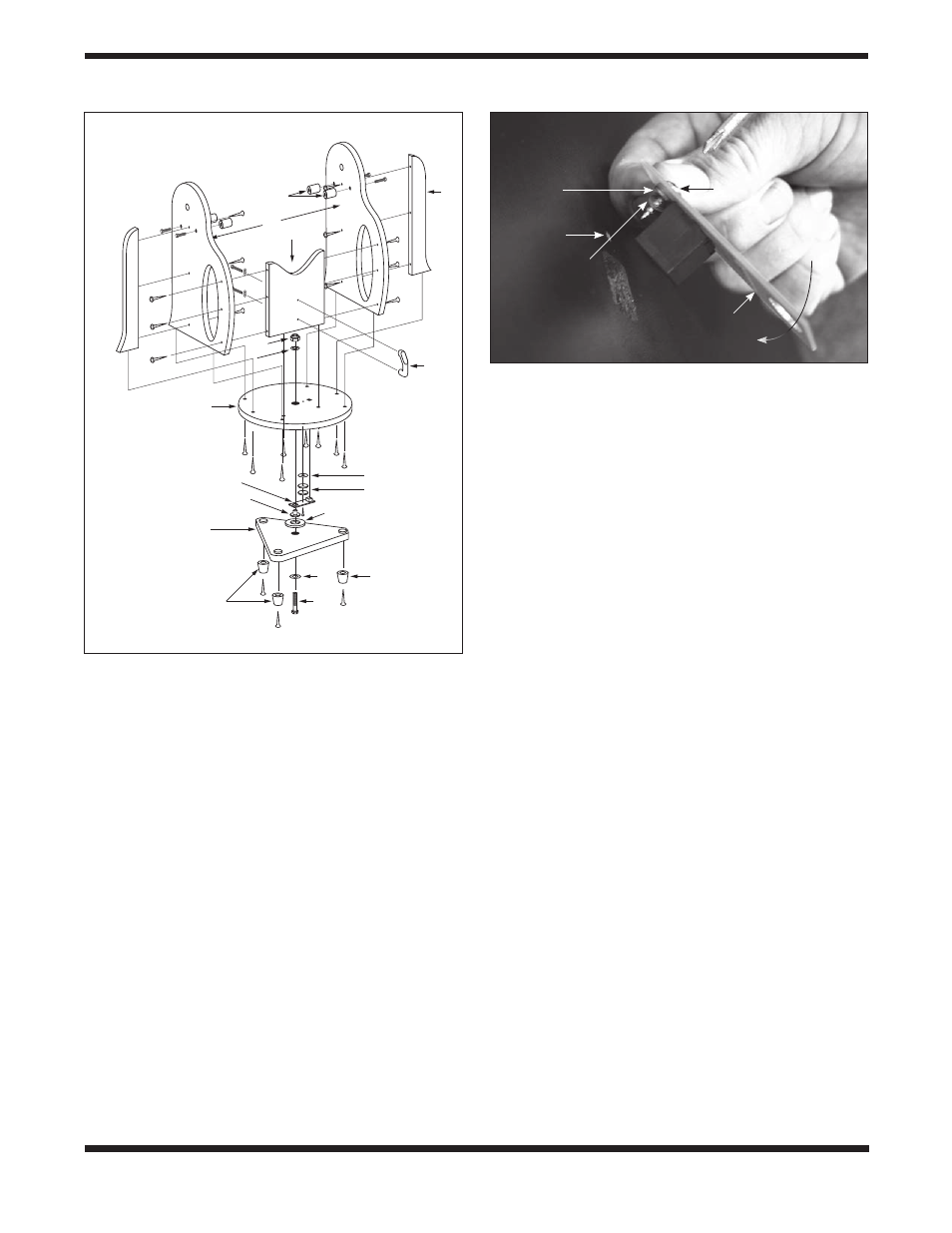

Figure 5.

Exploded view of the Dobsonian base.

Figure 6.

To install the azimuth encoder board, insert an encoder

board mounting screw through the slotted hole in the board. Then,

add two thick and one thin encoder spacing washers onto the

screw. Now, insert the modular connector on the encoder board into

the square hole in the the top baseplate, and thread the screw into

the pilot hole using a Phillips head screwdriver.

Azimuth encoder

spacer washers,

thick (2x)

Pilot hole

Azimuth encoder

spacer washer,

thin

Encoder

wood

screw

Azimuth

encoder

board

Top

baseplate