4 tractor ballast and tire settings, Getting on and off the tractor, Operation – Rhinotek 1645 User Manual

Page 52: Opera t ion

OPERATION

1640-1645 01/11

Operation Section 4-8

© 2010 Alamo Group Inc.

OPERA

T

ION

4. Getting On and Off the Tractor

3.4 Tractor Ballast and Tire Settings

To ensure tractor stability when operating a loader,

add wheel ballast, rear wheel weights, or 3-Pt

mounted Ballast Box with weight material. If 3-Pt

hitch ballast box is used, it should be carried as

low as possible at all times to maximize stability.

Effective counterbalance weight at the rear axle is

determined as follows (per ASABE EP562, March

2005)

A mass equivalent to the Lift Capacity to Max

Height (Specification V, refer to specifaction page

in the operationsection) should be placed in the

loader bucket.

Raise Loader until the bucket pivot pin is the same

distance from the ground as the Loader Boom

pivot pin.

On a hard level surface, measure the loads for the front and rear axles. Add these two numbers together to

determine the Gross Vehicle reaction.

Add Wheel Ballast, Wheel Weights, or 3-Pt Mounted Ballast as needed to adjust the reaction at the Rear Axle

to a minimum of 25% of the Gross Vehicle Reaction.

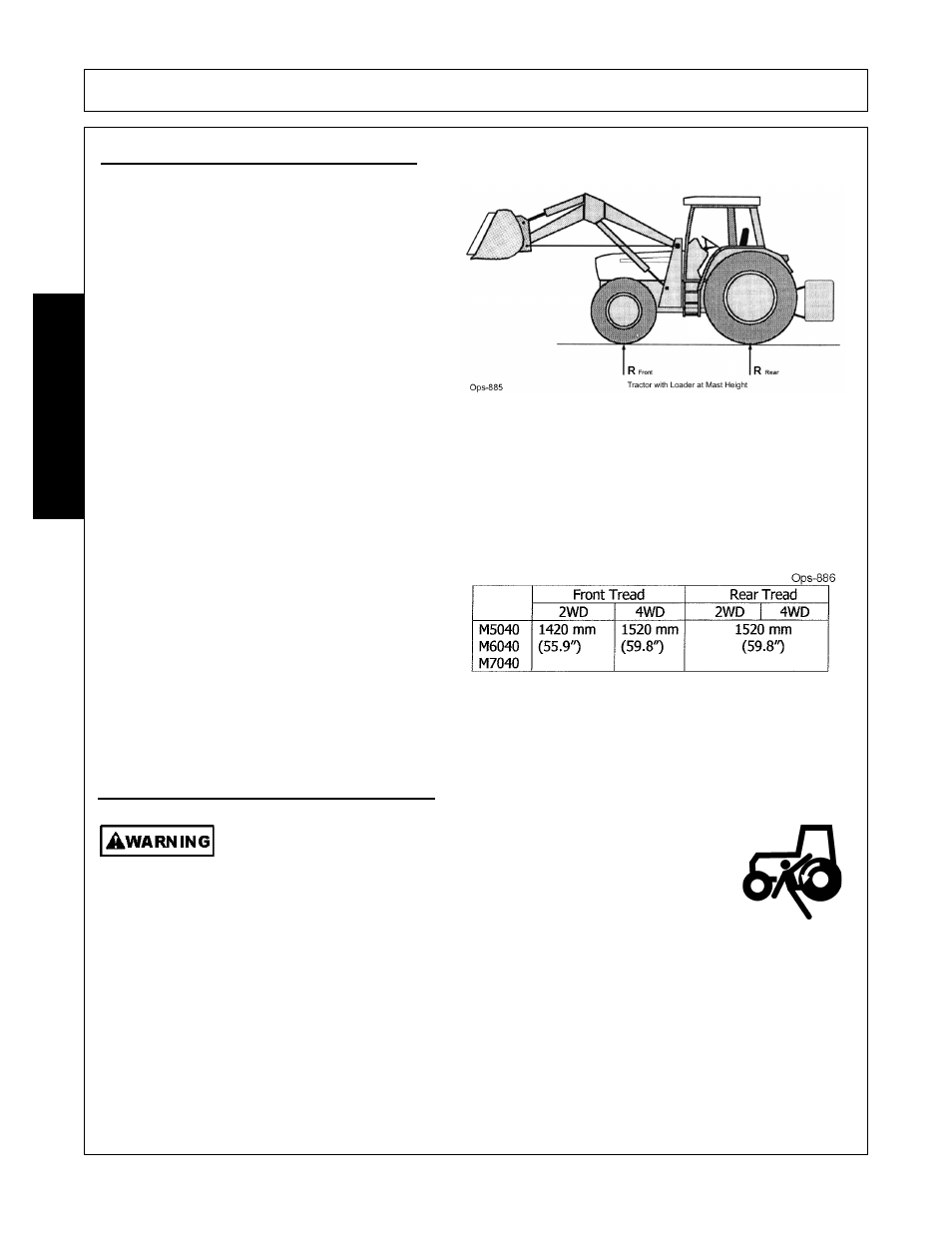

For better stability, adjust tractor wheels to the

manufacturer’s recommendations. See Chart 1

below for recommeded settings for the M5040,

M6040, and M7040 tractors.

OPS-L- 0017

Chart 1. Recommended Tread Settings

Do not mount or dismount the Tractor while the tractor is moving. Mount

the Tractor only when the Tractor and all moving parts are

completelystopped.

(SG-12)

Before getting onto the tractor, the operator must read and completely understand the implement and tractor

operator manuals. If any part of either manual is not completely understood, consult an authorized dealer for

a complete explanation. OPS-L- 0022