Troubleshooting – RIDGID 600 User Manual

Page 11

600 Power Drive

Ridge Tool Company

9

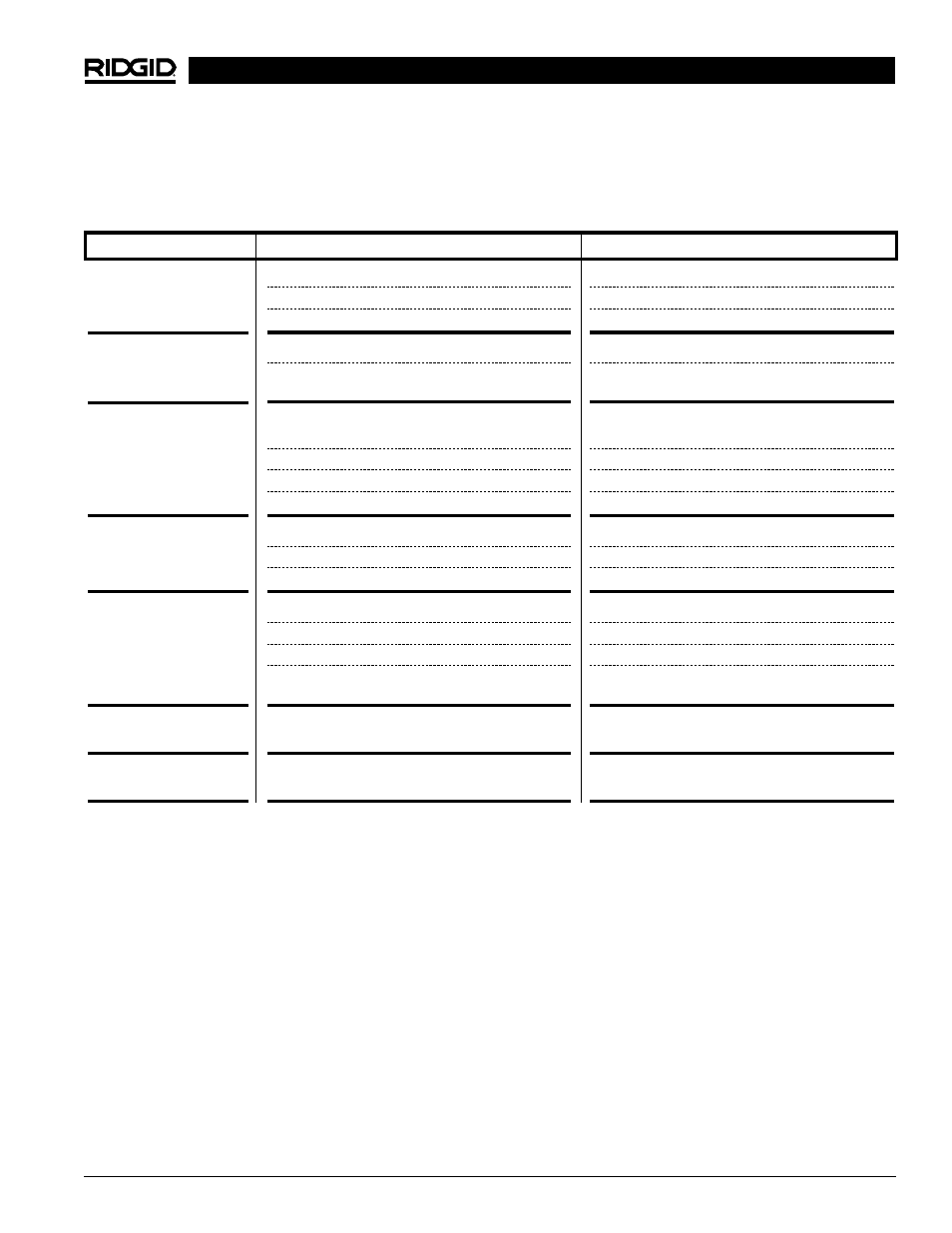

Troubleshooting

WARNING:

Always unplug power cord before servicing Power Drive.

Troubleshooting Table

Power drive unplugged

Fuse blown

Brushes do not touch armature

Overload because of dull dies

Bad quality or insufficient thread cutting oil

Bad contact between brushes and brush holder

Brushes do not touch commutator properly

Brushes of different manufacture

Sharp edge on brush

Dull or broken dies

Machine running in wrong direction

Improperly set dies

Dull dies

Dies not assembled in correct sequence

Low quality pipe

Bad quality or insufficient thread cutting oil

Support arm jaws dirty

Burr has occurred at the spline end of the die head

Plug into power source

Install new fuse

Check brushes, replace if worn

Replace dies

Use RIDGID thread cutting oil in adequate

quantity

Tighten the screws, make sure brush is pressed

firmly onto commutator

Replace worn brushes

Only use original brushes

Break edge

Replace dies

Check setting of the direction switch

Reset dies

Replace dies

Put dies in correct sequence

Make sure only pipe of good quality is used

Use only RIDGID thread cutting oil in adequate

quantity

Clean with wire brush

Eliminate burr with file

PROBLEM

CAUSE

CORRECTION

Motor does not start

Motor cannot be loaded

Sparks forming at motor

Die head does not start

threading

Damaged Thread

Support arm turns while

threading

Die heads cannot be

changed properly