14 error, maintenance and warranty – Rinnai Q175SN User Manual

Page 14

Operating instructions Rinnai Q-Series

14

Error, maintenance and warranty

If a fault is detected the boiler will be blocked.

This will be reflected, by an alternate display of

Good, with an

E

of Error or a

BL of Blocking and

a number code.

You can try to reset the boiler by pressing the

Reset key once. If the problem remains please

contact your installer and inform them about

the fault and give them the number code.

If you discover any leaks from the boiler

contact your installer.

We advise you to obtain a service contract

with your installer for regular maintance and

adjustment to keep your boiler safe and in

good condition.

The casing of the boiler consists of metal

and plastic parts which can be cleaned with a

normal non abrasive cleaning agent.

Periodic cleaning of the condensate collection and

disposal system must be carried out.

Before putting the boiler into operation after

periodic cleaning fill the condensate trap with

1.27 cups / 300 ml of water.

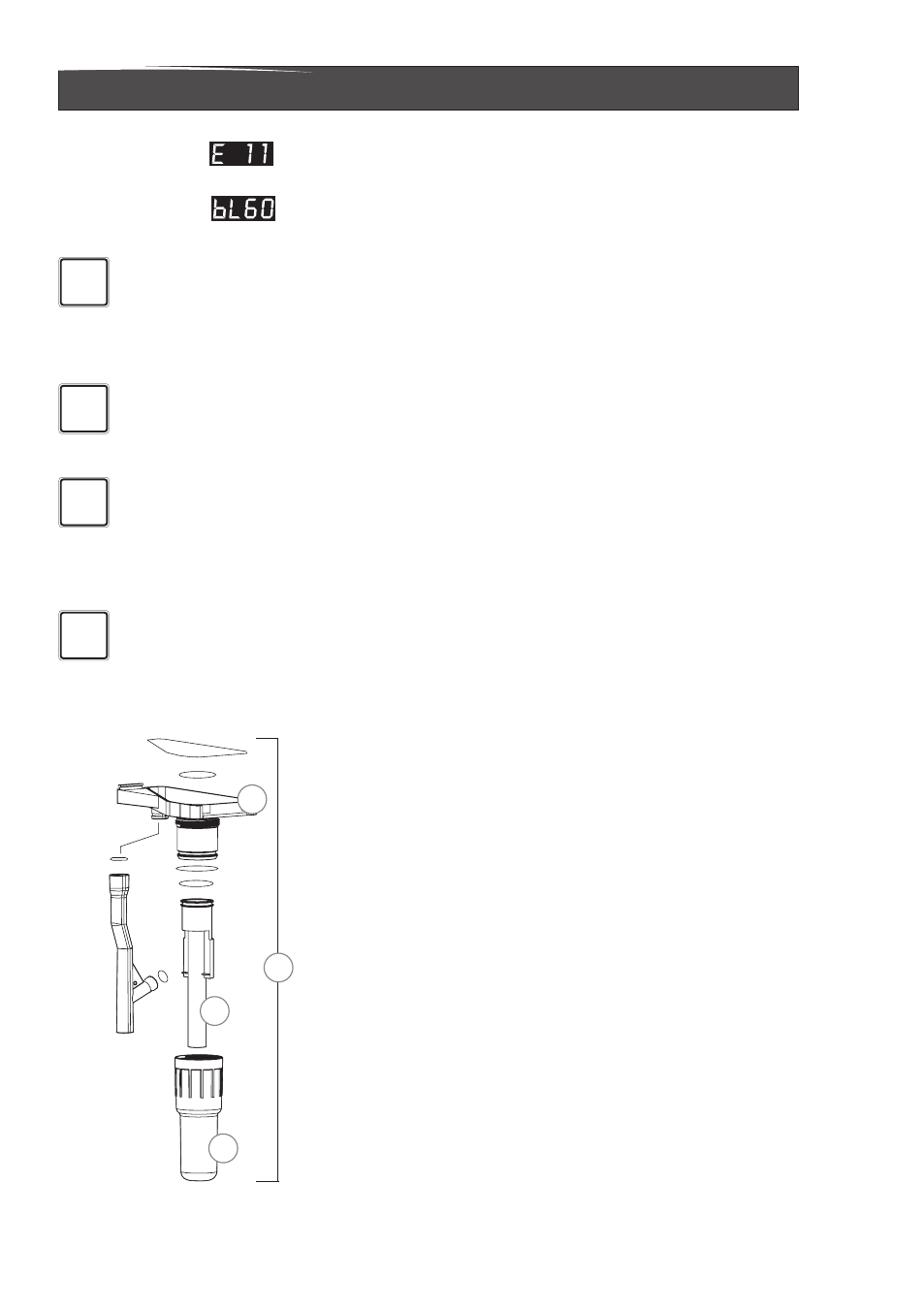

Step 1: Condensate trap

- First remove the condensation cup (7); Check

this for impurities. If there are no impurities it

is not necessary to clean the condensate cup

- Grease the O-rings again with acid free O-ring

grease to make fitting easier;

- If there is a leak at the condensation cup (7) or

tray (9) the complete condensate trap unit (10)

has to be replaced by # 809000054;

Step 2:

Refitting is done in reverse order.

Note that all gaskets seal completely.

NOTICE

i

NOTICE

i

NOTICE

i

NOTICE

i

7

8

9

10