Adjustments – RBH Sound RBH 180 User Manual

Page 22

20

– English

ADJUSTMENTS

tension bracket idler.

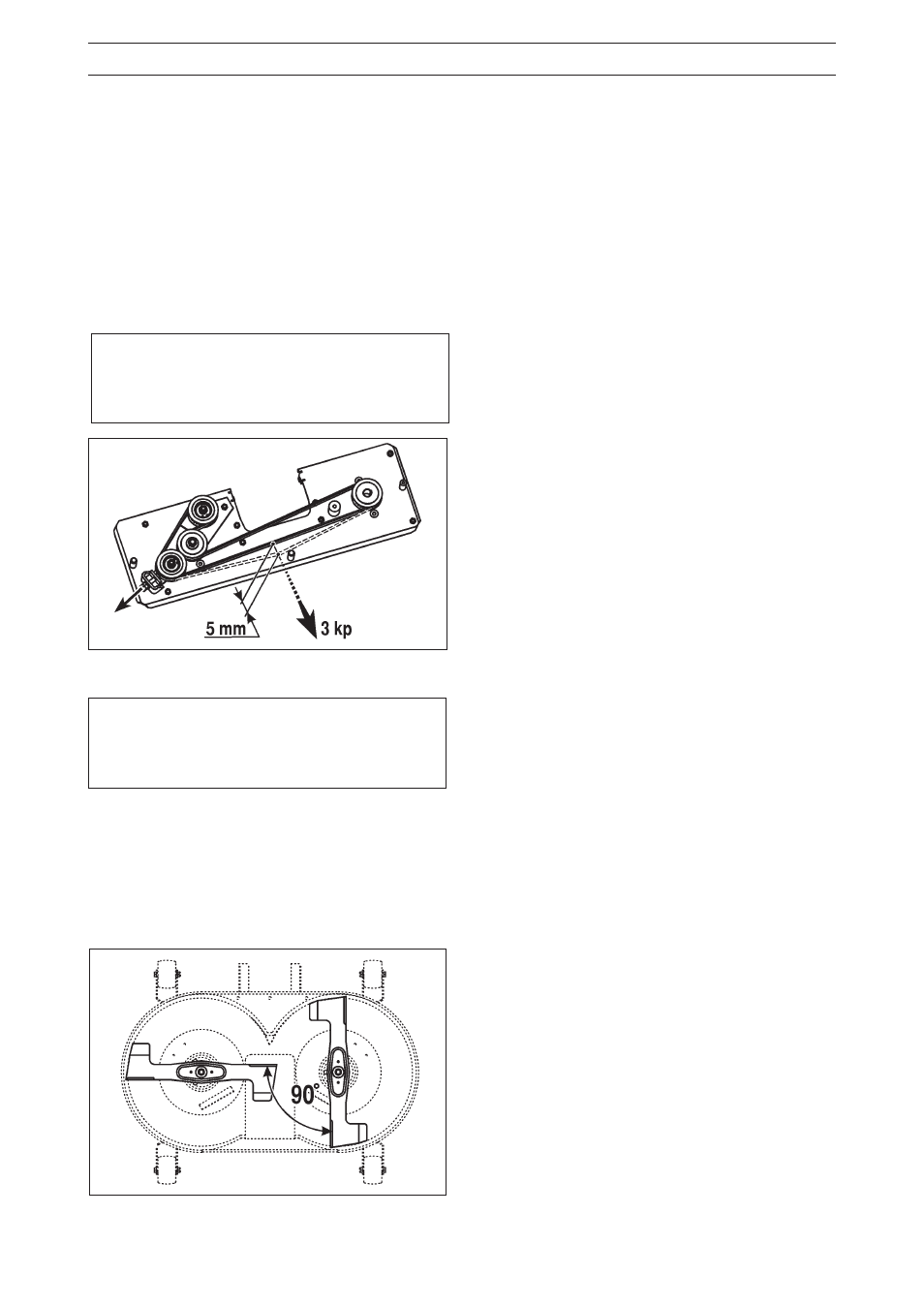

5. Adjust nut M10 until the specified tension at cog belt

is reached. (See Fig 33)

6

Re-tighten the two hex nuts on the cog idler pulley

and the belt is now adjusted correctly.

7. To re-install the cutting pan - reverse the procedure.

Note: It is possible but not desirable to adjust the cog

belt tension without removing the cutting pan assembly

form the tractor. In this case follow step 2 through 8

from the above procedures.

DANGER

This cog belt must be properly adjusted. If not, the

blades can contact and the belt will be destroyed and

the cutting system will be damaged.

Fig. 33

DANGER

On impact with any hard objects, the blade shear bolts

will break and the cog belt will be damaged!

The cog belt must be inspected.

Be careful!

The two blades must be positioned 90 degrees to each

other.

Replacement:

Use always genuine parts.

Fig. 34

TORQUE SPECIFICATIONS

Cutting system:

Mower cog belt

See Fig 33

Blade bolt LH

50 Nm

Blade bolt RH

50 Nm

Housing bolts M8x30

32 Nm

Self locking nut M12

(Pulley)

65 Nm

Hexagon socket screw

M8x20 (Idler arm)

25 Nm

Steering tooth gear fasteners:

Screw M8x30

15 Nm

Lock nut M12

80 Nm

Engine-transmission drive:

Exhaust screws

16 Nm

Crank shaft bolt

108 Nm

Screw M10x55

(Idler pulley-front)

25 Nm