Adjustments – RBH Sound RBH 180 User Manual

Page 21

English –

19

ADJUSTMENTS

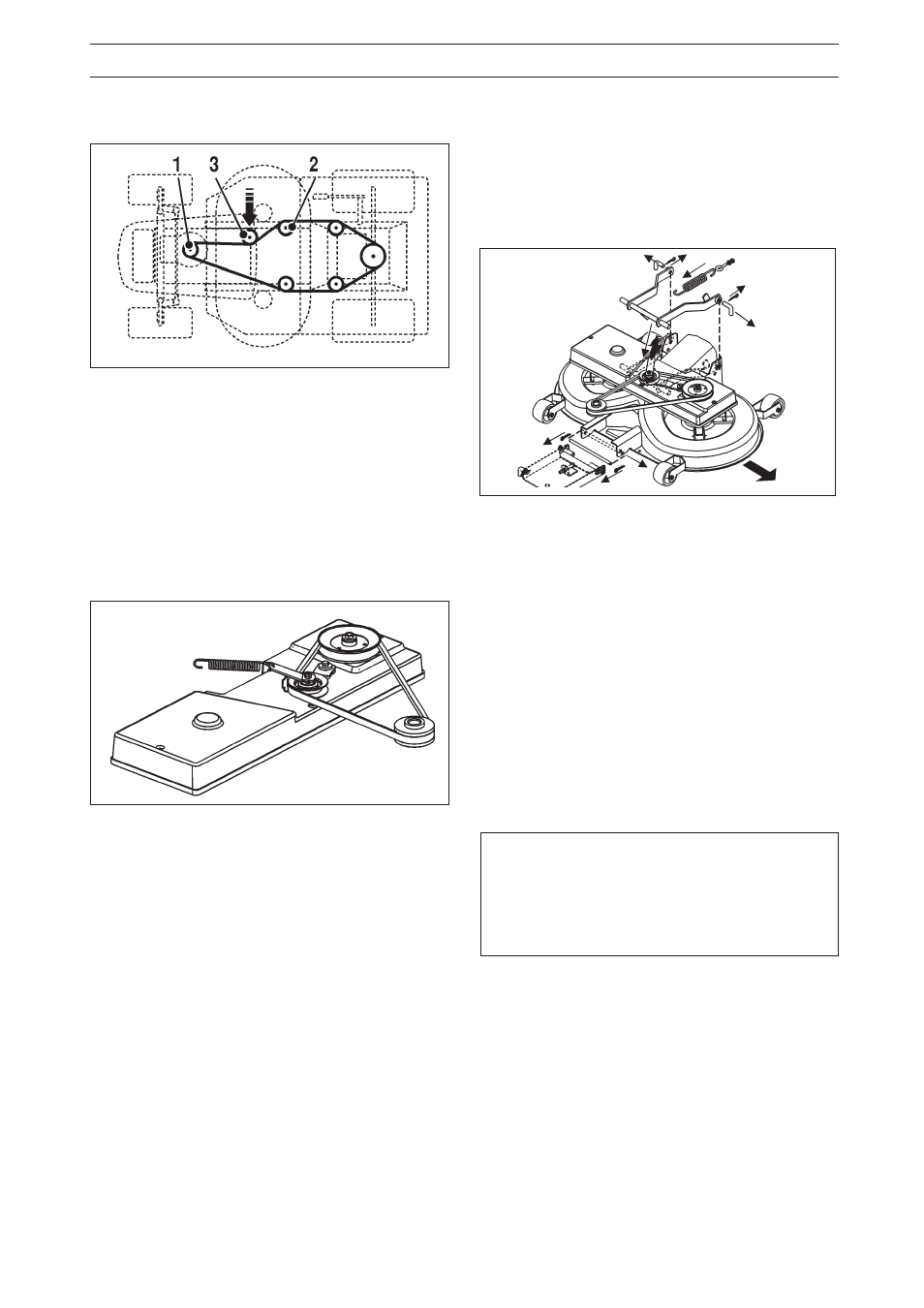

TRANSMISSION DRIVE BELT (FIG. 31)

Fig. 31

TRANSMISSION DRIVE BELT (FIG 31)

1.

engine pulley

2.

pulley

3.

idler pulley

Adjust the tension of the belt with the pulley 3.

MOWER CLUTCH BELT (FIG 32)

The tension of the belt is automatically adjusted with the

spring loaded idler pulley.

MOWER DECK BELT (FIG. 33)

ADJUST THE MOWER COG BELT

NOTE: It is recommended that the mower cog belt be

adjusted after 20 hours of operation as the new belts will

stretch slightly during the initial break in period.

1. engine pulley

2. pulley

3. idler pulley

Adjust the tension of the belt with the pulley 3.

MOWER CLUTCH BELT (FIG. 32)

The tension of the belt is automatically adjusted with the

spring loaded idler pulley.

A. CUTTING OAN REMOVAL (FIG 41)

1. Lower the cutting pan to the lowest position.

2. Pull idler arm assembly in and remove V belt

17x1400 from pulley.

3. Disconnect the spring from the engagement lever.

Fig. 41

4. Disconnect the plug connector from the air valve

switch in tunnel.

5. Lift tunnel to release the lower part from the two

welded pins that connect it to the mower deck

assembly.

6. Pull out tunnel rearwards approximately 10 cm.

Secure the tunnel to prevent it from falling back

down.

7. Remove the hair pin clips from front pin and from the

two rear pins.

NOTE: Altjough it is not necessary, it is recom-

mended to loosen the large spring for safety and to

facilitate reinstalation of cutting pan.

8. Pull out rear pin from one side and then use a pair of

pliers to pull second rear pin from other side.

CAUTION

If the large spring has not been loosened, the pivot

arm assembly will not spring up with force. Do not

place hands or fingers above the pivot arm assembly

and use pliers when pulling out second rear pin.

9. pull out fron pin

10. Remove V-belt from electro magnetic clutch

11. Slide cutting pan out from side of tractor

B. ADJUSTMENT PROCEDURES FOR

COG BELT TENSION

1. Remove cutting pan from tractor, follow procedure

described in A.

2. Remove V-belt pulley and idler arm assy.

3. Remove plastic belt cover.

4. Loosen the two hex nuts on the cog idler pulley on

Fig. 32