Maintenance – RBH Sound RBH 180 User Manual

Page 14

12

– English

After each cut, remove dirt and debris from the machine

surface, the discharge tunnel and the grass collector.

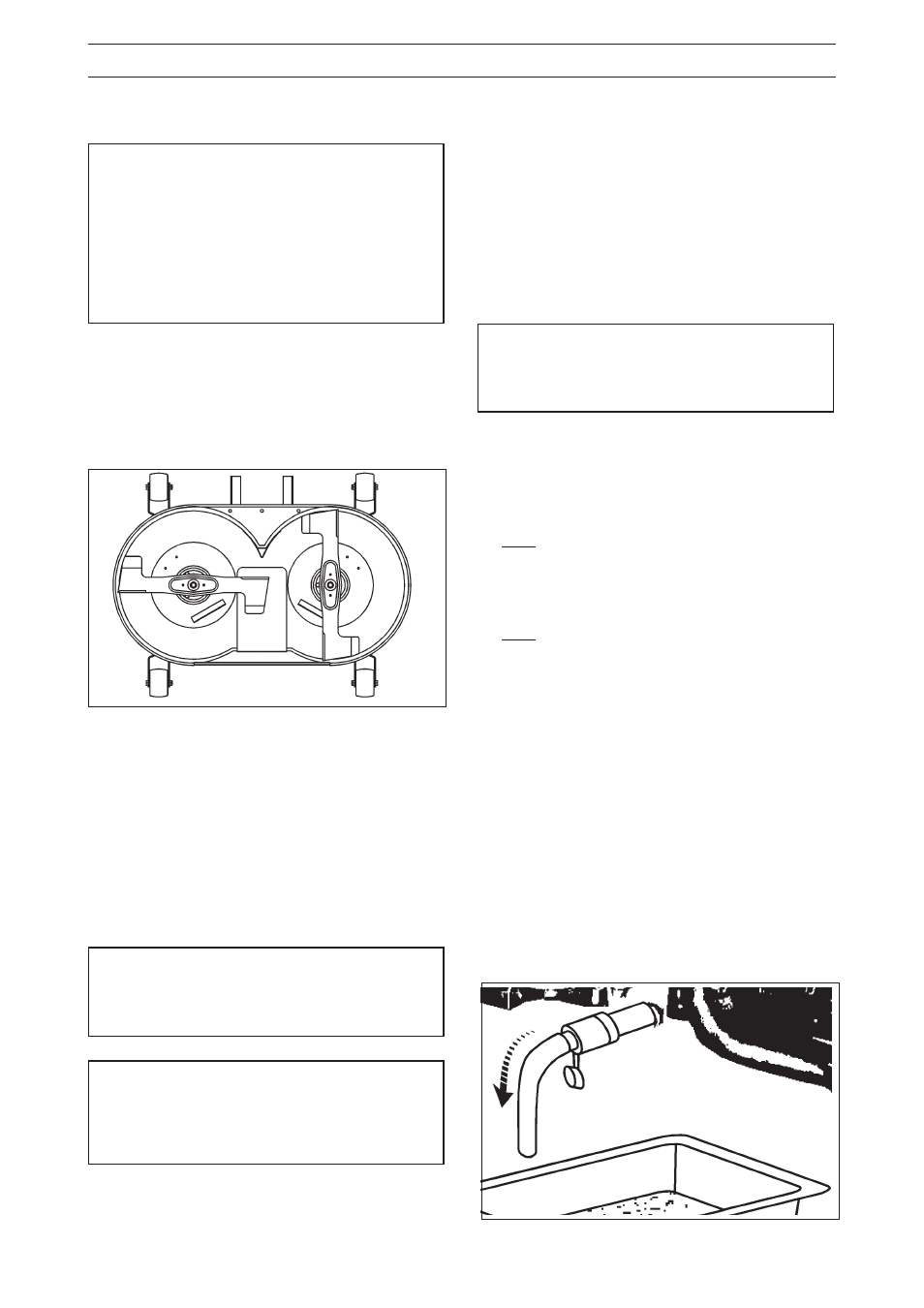

WASHING (FIG. 22)

MAINTENANCE

CLEANING

Before cleaning, washing, servicing or repairing,

remove the ignition key!

Always wear substantial steel toe foot wear, gloves

and work clothes.

Be aware of any spilled fuel, oil or other contaminat-

ing substances.

!

!

WARNING

Fig. 22

Proceed with the following:

1. Wash the tractor on a levelled surface, with

the grass collector mounted on.

2. Wash the inside of the mower deck, and the

discharge tunnel (engine off).

3. Dismount the grass collector, wash it, and

leave it off to let it dry.

4. Clean the plastic parts of the tractor with a

sponge and soap water.

Avoid water directly near the switches, the dash or

any electrical part.

!

!

BE CAREFUL

To clean the tractor never use high pressure washing

machines, or aggressive detergents.

ENGINE OPERATION

Follow the instruction described in the engine operator's

manual, for operation, service (air filter, fuel filter, oil

change, spark plugs, etc.)

CRANKCASE OIL CHANGE

Crankcase oil should be changed after the first 5 hours of

operation.

IMPORTANT

The warranty on this lawn tractor does not cover items

that have been subjected to operator abuse or negligence.

To receive full value from the warranty, operator must

maintain lawn tractor as instructed in this manual. The

following maintenance check list is supplied to assist

operator to properly maintain lawn tractor. This is a

check list only. Adjustments referred to will be found in

the Adjustment section of this manual.

Your tractor is equipped with an oil drain plug.

1. Place a flat bottom 2 litres container beneath the

oil valve.

Note: It may be necessary to raise the left side

of the tractor (with blocks under left wheels) to

get proper drainage.

2. Turn the oil valve counterclockwise, and pull

to drain oil.

Note: The oil fill cap should be loosened to

serve as an air vent.

3. To close oil drain valve, push and turn

clockwise.

4. Fill with grade SAE 30 or SAE 10W/30W oil.

5. Reinstall the oil cap.

6. Check that the crankcase oil is at the correct level on

the oil dip stick.

IMPORTANT

See engine operating and maintenance manual for

proper procedure.