Maintenance and repair instructions specifications, Troubleshooting – Ryobi 105r User Manual

Page 14

14

MAINTENANCE AND

REPAIR INSTRUCTIONS

SPECIFICATIONS

MOTOR

Motor type . . . . . . . . . . . . . . . . . . . . . . . . . Electric

Operating RPM . . . . . . . . . . . . . . 7,000-7,800 rpm

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . Trigger

Amperage . . . . . . . . . . . . . . 4.7 amps - Model 105r

5.2 amps - Model 132r

5.5 amps - Model 137r

DRIVE SHAFT AND CUTTING HEAD

Drive Shaft . . . . . . . . . . . . . . . . . . . 1/4 in (6.5 mm)

Shoulder Strap . . . . . . . . . . . . . . . . . . . . . Optional

Cutting Head . . . . . . . . . . . . . Bump Line Releaser

Cutting Path Diameter . . . . . . . . . . 15 in (381 mm)

Drive Shaft Housing . . . . . Steel Tube - Model 105r

Steel Tube, Click-Link,

Models 132r and 137r

Trimming Line Diameter . . . . . . 0.060 in (1.52 mm),

Model 105r

0.080 in (2.03 mm),

Models 132r and 137r

CLEANING THE TRIMMER

WARNING: To avoid serious personal

injury, always unplug your unit before

you clean or perform any maintenance

on it.

1. Use a small brush or the air discharge of a

vacuum cleaner brush to clean the fan

blades.

2. Keep the air vents free of obstructions.

3. Do not use any strong detergents on the

plastic housing or handle. They can be

damaged by certain household cleaners that

contain aromatic oils such as pine and

lemon, and by solvents such as kerosene.

Moisture can also cause a shock hazard.

Wipe off any moisture with a soft cloth.

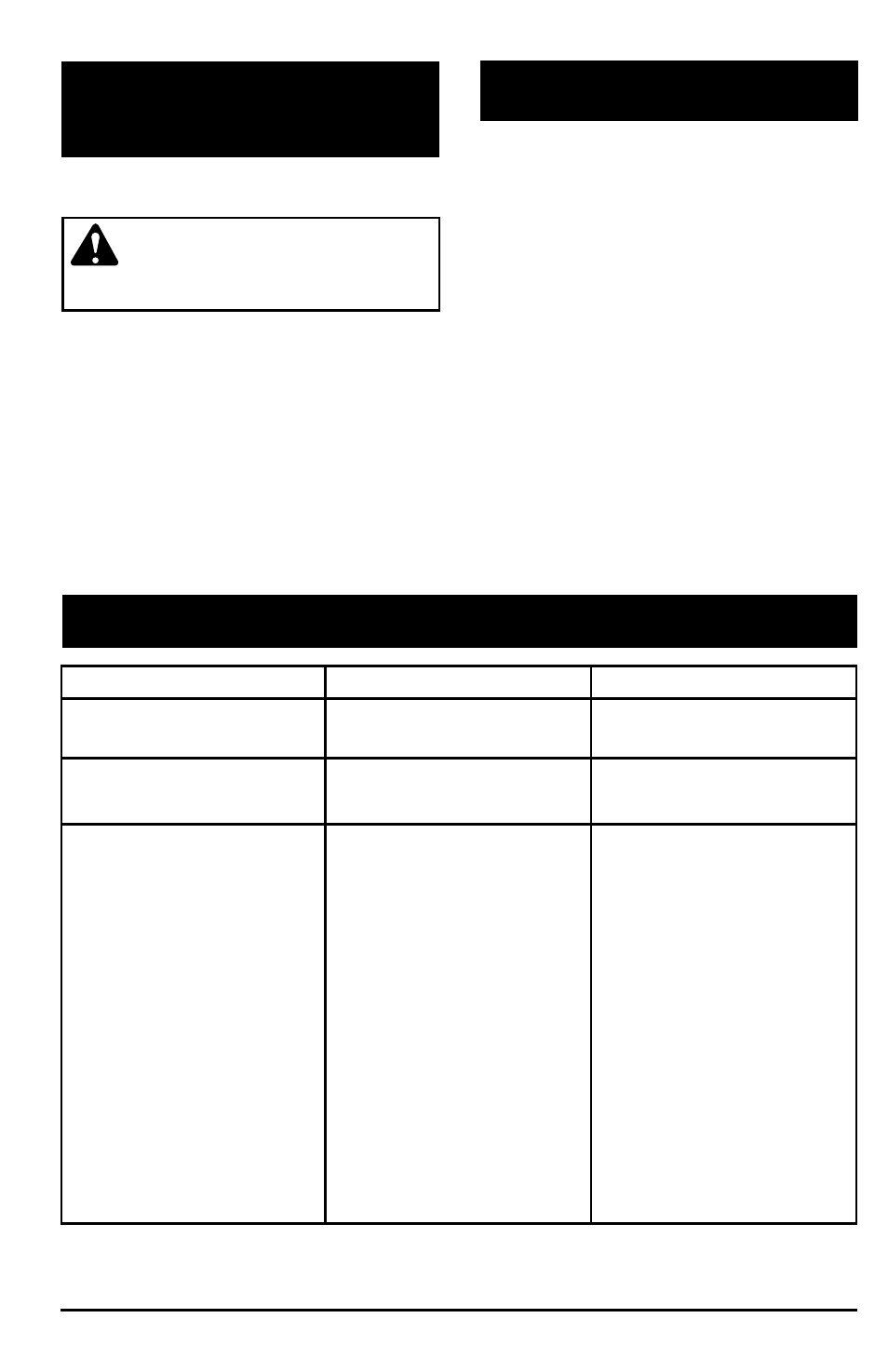

TROUBLESHOOTING

PROBLEM

Motor Will Not Start

Cutting Head Will Not Turn

When Trigger is Squeezed

Cutting Head Will Not

Advance Line

CAUSE

Motor stops, unit unplugged

Cutting head bound with grass

or debris

Cutting head out of line

Inner reel bound up

Cutting head dirty

Indexing teeth worn or burred

Line welded

Line twisted when refilled

Not enough line exposed

REMEDY

Check cord to see if it is plugged

into an electrical outlet

Stop motor and clean cutting

head

Refill with genuine replacement

cutting line

Replace inner reel

Clean cutting head reel/spool

Replace reel and spool

Disassemble, remove the welded

section, and rewind the line

Disassemble cutting head and

rewind the inner reel

Push the Bump Knob and pull

out the line until a minimum of

4 in (102 mm) is outside of

cutting head