Heater sequence of operation – Raypak WH & P L W User Manual

Page 34

34

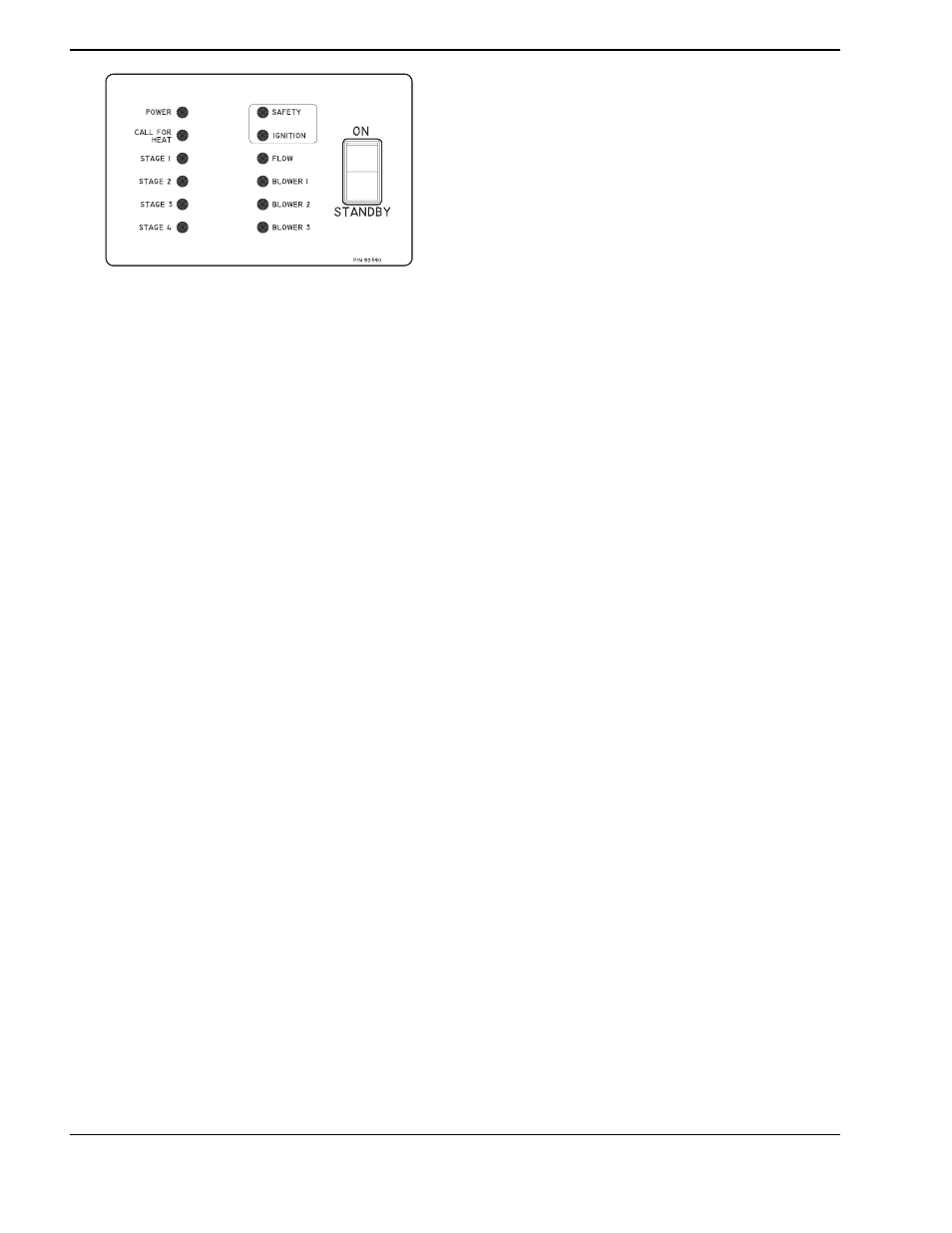

Fig. 31: External LED Indicator Decal

Heater Sequence of Operation

Models 992A-1262A

1.

The black (hot) wire lead goes directly to the main

power switch. This black toggle switch is located

at the middle front of the control compartment.

2.

When the main power switch is placed in the “ON”

position, 120 VAC is applied to the 120 VAC termi-

nal block on the circuit board and the 120/24 VAC

transformer is powered.

3.

120 VAC is waiting at the N.O. contacts of the

Economaster II pump delay.

4.

Terminals L1 and F1 of the ignition module are

powered with 120VAC.

5.

120 VAC power is also applied to the control

power connector on the circuit board.

6.

120 VAC power is waiting at relay contacts K-3 to

energize the heater blower.

7.

The 120/24 VAC transformer outputs 24 VAC.

8.

24 VAC is sent to the low water cut-off (optional)

and the red power light is energized.

9.

24 VAC is applied to the blue power light located

on the diagnostic display board.

10. 24 VAC is also applied to the red LED safety shut-

down light on the front diagnostic board.

11. 24 VAC is applied to the alarm circuit (optional). If

the E-5 sales option (Alarm) is included a 5 sec-

ond time delay relay will not allow the alarm to

sound unless the circuit stays energized for more

than 5 seconds.

12. Power is applied to terminal P1-1 of the Universal

Diagnostics Board. All safeties are verified to

ensure that it is safe to operate the heater. The

safety components wired into the diagnostic board

are: low water cut-off (optional), blocked vent

switch, manual vent temp switch (optional), manu-

al reset high limit, low gas pressure switch (option-

al), high gas pressure switch (optional), and auto-

reset high limit (optional).

13. Power is applied to terminal TP-1 of the

Economaster II pump delay to energize the circuit

board.

14. Once all safeties have been verified to be closed,

a 24 VAC signal is output from pin P3-16 of the

Universal Diagnostic Board.

15. Relay K-1 (N.C.) will now be energized, and opens

the N.C. contacts to disable the alarm (optional)

and turns off the red safety shutdown light.

16. Pin P1-4 on the diagnostic board will now output a

24 VAC signal to pin 1 of the “standby switch”.

17. The “standby switch” (rocker switch) located at the

lower left front of the control compartment is now

powered. If the switch is “ON” and there is no call

for heat (CFH), the heater is in standby mode.

18. After the standby switch is placed into the “ON”

position, a 24 VAC signal is sent to the

“enable/disable” connection (normally jumpered).

19. 24 VAC switched power is applied to the S24V ter-

minal on the ignition module.

20. When the “enable/disable” contacts are closed,

the 24 VAC signal travels to pin 1 of the stage 1

connection and waits for a CFH.

21. When a CFH occurs, a 24 VAC signal is sent to the

CFH light on the diagnostics panel located on the

lower left front of the control compartment.

22. Power is now sent to terminal TP4 of the

Economaster II to energize the relay and close the

contacts.

23. The heater pump is energized upon relay closure

of the Economaster II.

24. Upon sufficient flow from the heater pump, the

flow switch contacts will close.