Operation – RIDGID R3203-1 User Manual

Page 16

16

OPERATION

ADJUSTING BLADE DEPTH

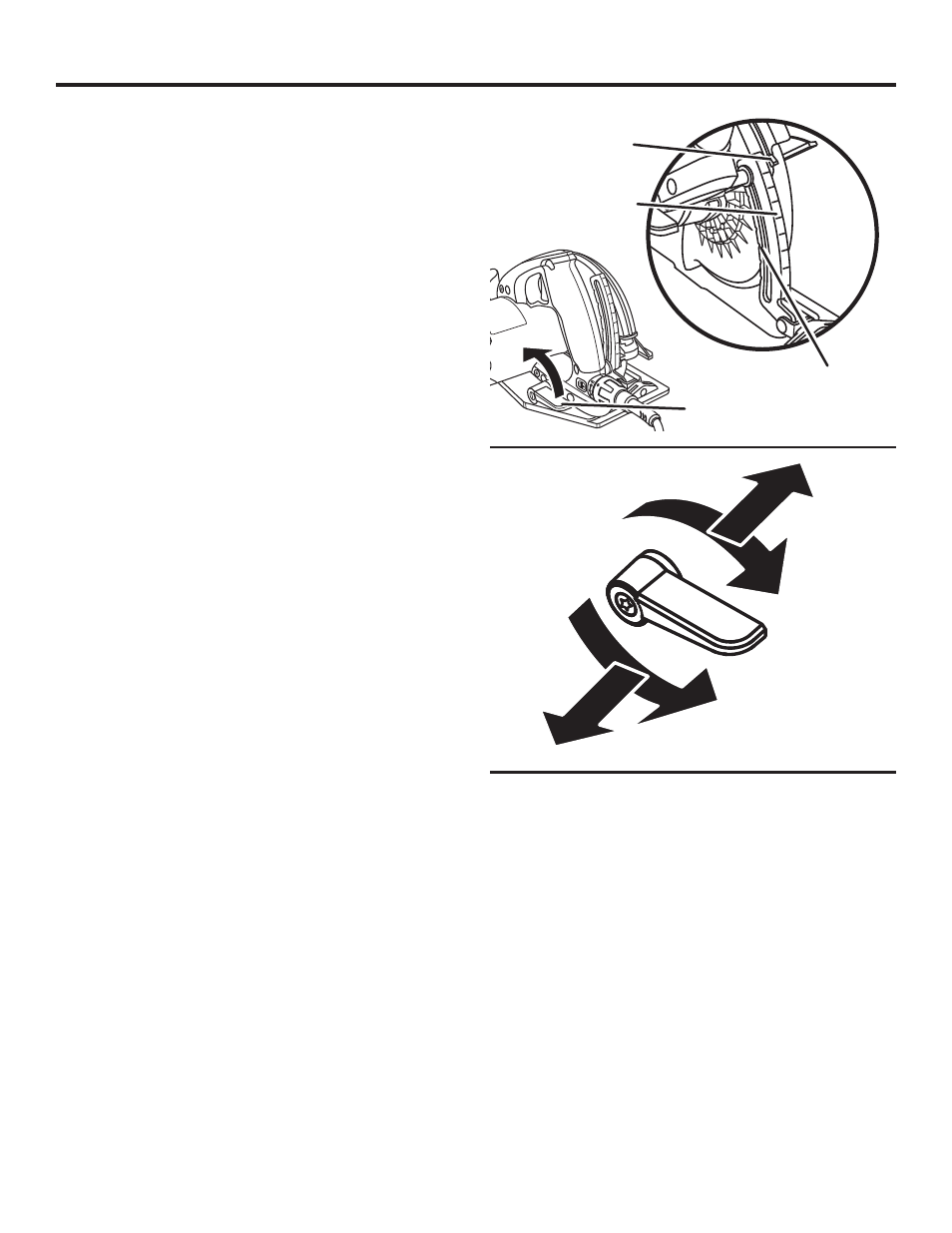

See Figures 12 - 13.

Always keep correct blade depth setting. The correct blade

depth setting for all cuts should not exceed 1/4 in. below

the material being cut. More blade depth will increase the

chance of kickback and cause the cut to be rough.

Unplug the saw.

Pull depth adjustment lever upward to release.

Determine the desired depth of cut.

Hold base flat against the workpiece and raise or lower

saw until the indicator mark on the saw aligns with the

desired depth on the scale.

Push down on depth adjustment lever to lock into

position.

INDEXING LEVERS

See Figure 13.

The levers on the saw can be repositioned for the best

tightening position.

Pull the lever out from the saw and move to desired

position.

Push lever back in and down to lock into place.

Check to be sure the base is clamped securely.

PLYWOOD ID SYSTEM

See Figure 12.

Indicators along the elevation bracket help to quickly identify

the following common plywood thicknesses: 1/4, 3/8, 1/2,

5/8, 3/4, and 1 in. A “click” can be heard as the saw is moved

from one thickness setting to the next.

Unplug the saw.

Pull depth adjustment lever upward to release.

Determine the thickness of the workpiece.

Hold base flat against the workpiece and raise or lower saw

until the saw clicks into the correct thickness setting.

Push down on depth adjustment lever to lock into

position.

NOTE: Saw teeth will extend slightly further than the selected

thickness setting to allow the blade to pass completely

through the workpiece.

Fig. 12

DEPTH OF CUT SCALE

DEPTH ADJUSTMENT

LEVER

DEPTH INDICATOR

Fig. 13

PUSH IN AND

DOWN TO LOCK

PULL OUT AND UP

TO RATCHET

PLYWOOD ID SYSTEM