Operation – RIDGID AUTOSHIFT R86014 User Manual

Page 10

0

OPERATION

CAUTION:

To prevent gear damage, always allow the chuck

to come to a complete stop before changing the

direction of rotation.

To stop the drill, release the switch trigger and allow the

chuck to come to a complete stop.

NOTE: The drill will not run unless the direction of rotation

selector is pushed fully to the left or right.

Avoid running the drill at low speeds for extended periods

of time. Running at low speeds under constant usage may

cause the drill to become overheated. If this occurs, cool the

drill by running it without a load and at full speed.

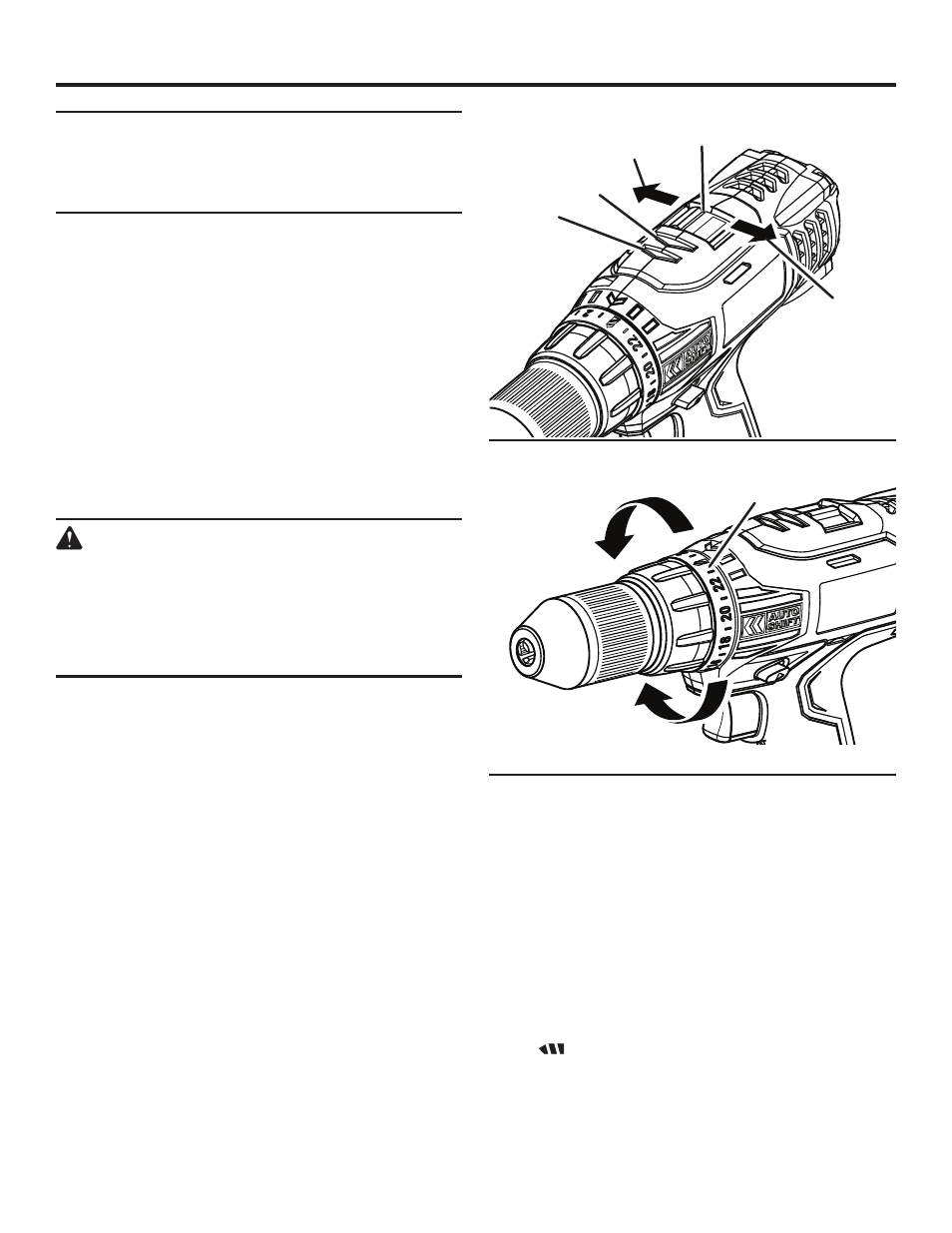

KEYLESS CHUCK

See Figure 4.

The drill has a keyless chuck to tighten or release drill bits

in the chuck jaws. The arrows on the chuck indicate which

direction to rotate the chuck body in order to

GRIP (tighten)

or

OPEN (release) the drill bit.

WARNING:

Do not hold the chuck body with one hand and use

the power of the drill to tighten the chuck jaws on

the drill bit. The chuck body could slip in your hand,

or your hand could slip and come in contact with

the rotating drill bit. This could cause an accident

resulting in serious personal injury.

AutoShift

™

SELECTOR

See Figure 5.

The mode selector switch on top of the drill has two settings:

HIGH and AutoShift

™

.

When

AutoShift

™

is selected, the drill starts in high speed

when the trigger is pulled. The blue LED arrow indicates that

the drill is in

HIGH speed.

During drilling, if the load increases so that more torque is

required, the drill automatically shifts from high speed to

low speed.

The amber LED arrow indicates that more torque is required

and the drill has AutoShifted into low speed.

When

HIGH is selected, the drill will stay in high speed and

will not automatically shift to a lower speed. The variable

speed switch trigger should be used to control speed.

ADJUSTABLE TORQUE CLUTCH

This product is equipped with an adjustable torque clutch

for driving different types of screws into different materials.

The proper setting depends on the type of material and the

size of screw you are using.

HIGH

Fig. 5

HIGH

AutoShift

™

SELECTOR

TO DECREASE

TORQUE

TO INCREASE

TORQUE

ADJUSTING

RING

AutoShift

™

Fig. 6

AMBER

LED

BLUE

LED

ADJUSTING TORQUE

See Figure 6.

There are twenty-four torque indicator settings located on

the front of the drill.

Rotate the adjusting ring to the desired setting.

• - 4

For driving small screws

• 5 - 8

For driving screws into soft material

• 9 -

For driving screws into soft and hard

materials

• 3 - 6 For driving screws into hard wood

• 7 - 4 For driving large screws

•

For heavy drilling