Raypak 055B User Manual

Page 12

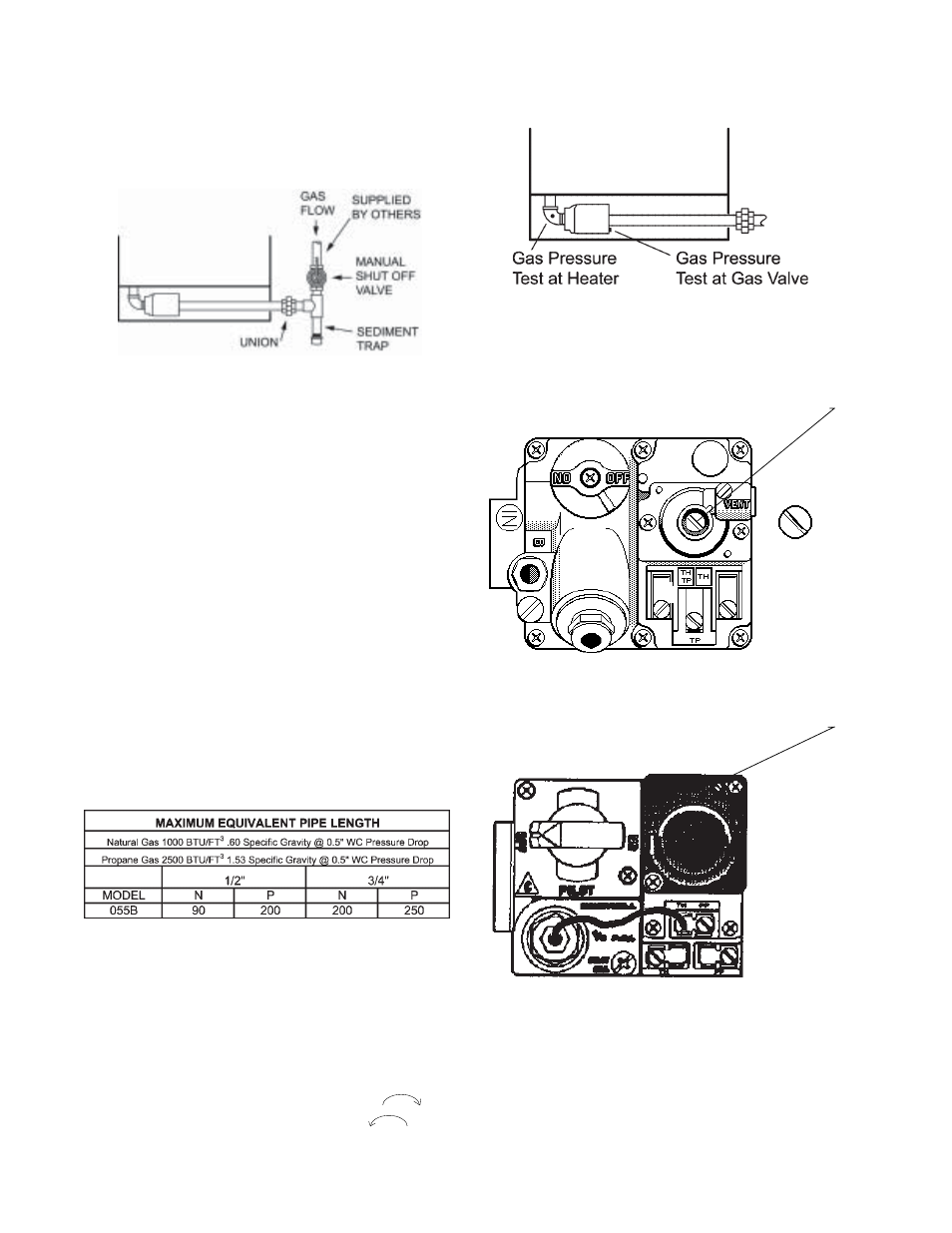

GAS SUPPLY CONNECTIONS

Gas piping must have a sediment trap ahead

of the heater gas controls, and a manual shut-off valve

located outside the heater jacket. All gas piping should

be tested after installation in accordance with local

codes.

CAUTION: The heater and its manual shut off valve

must be disconnected from the gas supply during any

pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 KPA). Dissipate test pressure

in the gas supply line before reconnecting the heater

and its manual shut off valve to gas supply line.

FAILURE TO FOLLOW THIS PROCEDURE MAY

DAMAGE THE GAS

VALVE. OVER PRES-

SURED GAS VALVES ARE NOT COVERED BY

WARRANTY. The heater and

its gas connections

shall be leak tested before placing the appliance in

operation. Use soapy water for leak test. Do NOT

use open flame.

NOTE: Do not use teflon tape on gas line pipe thread.

A flexible sealant is recommended.

A minimum of 7" W.C. and a maximum of 14" W.C.

upstream pressure under load, and no load conditions

must be provided for natural gas or a minimum of 12"

W. C. and a maximum of 14" for propane gas.

12

Fig. # 9421

ROBERTSHAW MV

HONEYWELL VALVE MV & IID

W.C Adjustment

W.C Adjustment

Fig. # 8199

Fig. # 8081.0

GAS PRESSURE REGULATOR

The gas pressure regulator is preset and sealed at

4" W.C. for natural gas, and ll" W. C. for propane gas.

Between the gas valve and the burners is a l/8" pipe

plug. The pressure at this point, taken with a manome-

ter, should be about 3.7" W. C. natural gas and l0.5"

W.C. propane gas. If an adjustment is needed, remove

seal and turn adjustment screw clockwise to

increase pressure or counter-clockwise to

decrease pressure.

PIPE SIZING FOR GAS CONNECTIONS

Fig. # 9420