Installing the storage tank, Temperature and pressure relief valve, Vacuum relief valve – Rheem Marathon Thermal MTS105200 User Manual

Page 6: Drain pan

6

A new combination temperature and pressure relief valve, complying with the Standard for Relief

Valves and Automatic Gas Shut-Off Devices for Hot Water Supply Systems, ANSI Z21.22, is supplied

and must be installed in the opening provided and marked for the purpose on the storage tank. No

valve of any type should be installed between the relief valve and the tank. Local codes shall govern the

installation of relief valves.

!

WARNING: The

pressure rating of the

relief valve must not

exceed 150 PSI, the

maximum working

pressure of the storage

tank as marked on

the rating plate.

Temperature and Pressure Relief Valve

Connect the outlet of the relief valve

to a suitable open drain so that the

discharge water cannot contact live

electrical parts or persons and to

eliminate potential water damage.

Piping used should be of a type

approved for hot water distribution.

The discharge line must be no smaller

than the outlet of the valve and must

pitch downward from the valve to

allow complete drainage (by gravity)

of the relief valve and discharge line.

The end of the discharge line should

not be threaded or concealed and

should be protected from freezing.

No valve of any type, restriction or

reducer coupling should be installed in

the discharge line.

Vacuum Relief Valve

NOTICE: Do NOT

remove or tamper with

the vacuum relief valve for

any reason. Doing so will

void the manufacturer’s

warranty.

The vacuum relief valve, which must

be used when installing the storage

tank, is factory installed.

The cold water inlet has a vacuum

relief valve installed. Certain

conditions in the field may produce a

vacuum or negative pressure condition

inside the storage tank. This negative

pressure can cause the tank to fail.

The vacuum relief valve provides

a means to eliminate the negative

pressure or vacuum by admitting air

into the tank to equalize the pressure.

It is not recommended to pull a

vacuum on the unit.

If a vacuum is pulled on the unit,

refer to the "To Fill the Storage tank"

section to ensure the unit is full of

water before operating.

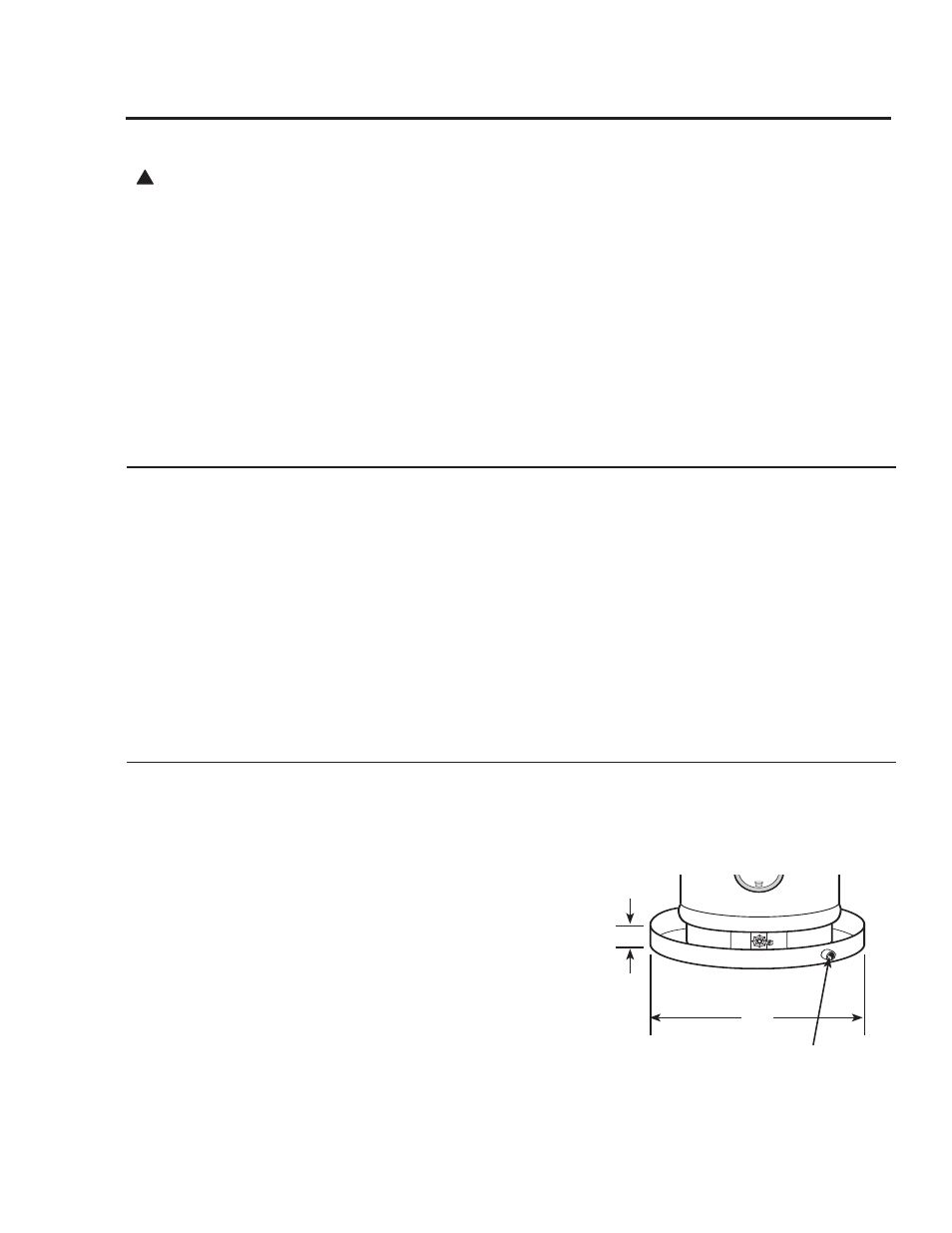

Installing the storage tank.

NOTICE: Auxiliary

catch pan MUST

conform to local

codes.

The storage tank should not be

located in an area where leakage of

the tank or connections will result in

damage to the area adjacent to it or

to lower floors of the structure. It is

recommended that a suitable catch

pan, adequately drained, be installed

under the storage tank.

Catch pan kits are available from

the store where the storage tank

was purchased, or any water heater

distributor.

Under no circumstance will the

manufacturer be held liable for any

water damage in connection with this

storage tank.

■■■✦■■■

B

A

To open drain, this line should be at least 3/4

s ID and

pitched for proper drainage.

B = Max 2

s

A = Diameter of

storage tank

plus 2

s min.

Drain Pan