Vent piping – Raypak P-R185BL to P-R405BL User Manual

Page 17

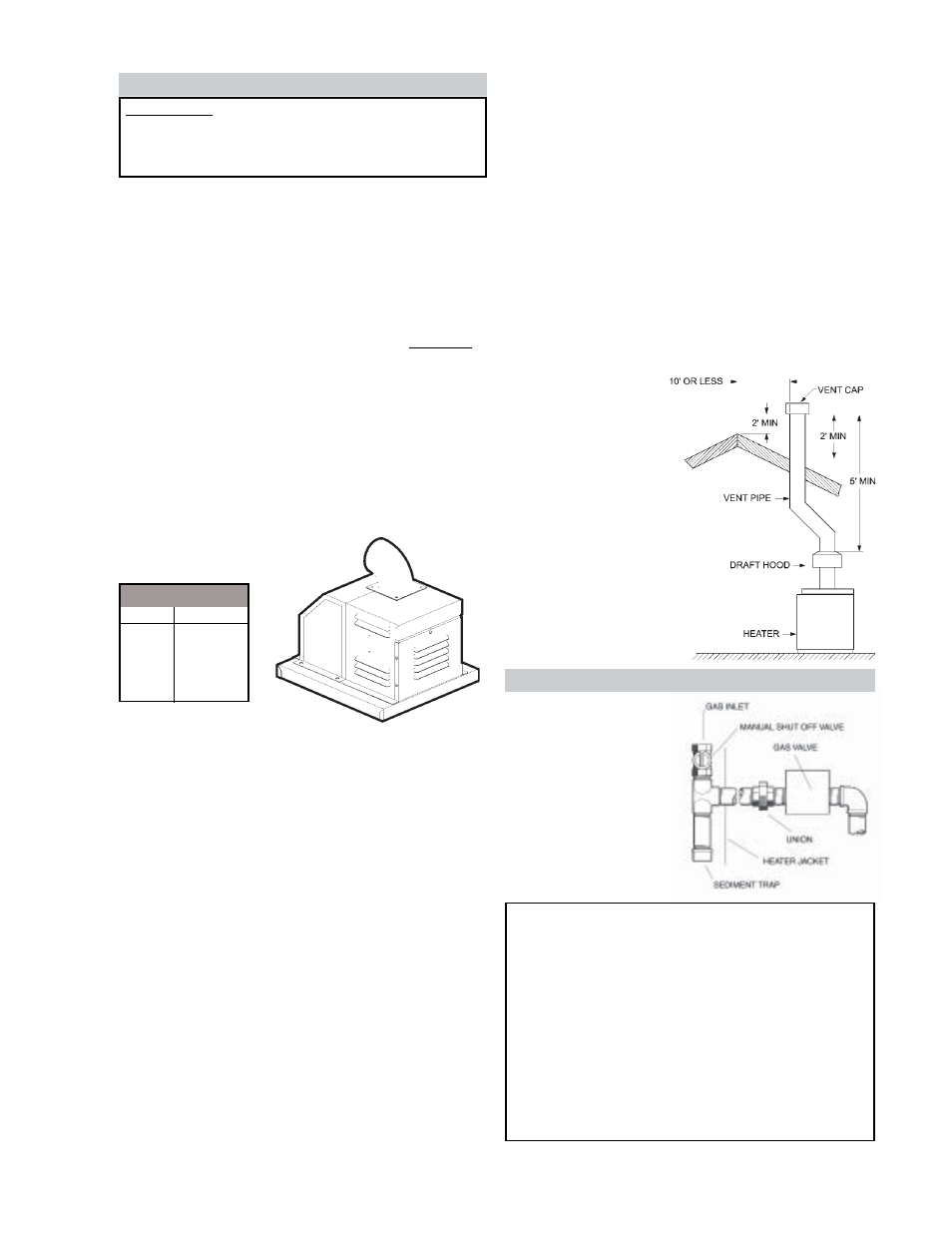

VENT PIPING

Vent piping the same size as the draft hood outlet is

recommended, however, when the total vent height is at

least ten (10) feet (draft hood relief opening to vent

terminal), the vent pipe size may be reduced as speci-

fied in Chapter 10 of the National Fuel Gas Code, ANSI

Z 223.1 (Canada-CAN/CGA-B149.1 and B149.2). As

much as possible avoid long horizontal runs of vent pipe

and too many elbows. If installation requires horizontal

non-vertical runs, the vent pipe must have a minimum of

1/4 inch per foot rise and should be supported at not more

than five foot intervals. Plumbers tape, criss-crossed, will

serve to space both horizontal and vertical piping. Gas

vents supported only by the flashing and extending above

the roof more than five feet should be securely guyed or

braced to withstand snow and wind loads. We recom-

mend use of insulated vent pipe spacer through the roofs

and walls. Another option for installation that requires

horizontal runs is using the D-2 power vent kit option.

For more detailed D-2 installation information consult the

D-2 Power Vent manual 6000.57.

The power vent assembly is a fan-assisted combustion

system designed for application to Raypak Pool Heater

Models 185-405. The unit, when installed as directed, is

capable of operating in applications such as through-the-

wall venting and reduced horizontal and vertical vent pipe

sizes in new and current installations. It is certified for

Category III venting up to 40 feet equivalent 4" diameter

venting. The unit is factory wired for 240V, with capability

of rewiring for 120V.

For protection against rain or blockage by snow, the vent

pipe must terminate with a vent cap which complies with

the local codes or, in the absence of such codes, to

the latest edition of the National Fuel Gas Code, ANSI

Z223.1 (Canada-CAN/CGA-B149.1 and B149.2).

Fig. #RP 8119.2

17

GAS SUPPLY CONNECTIONS

The discharge opening must be a minimum of two feet

vertically from the roof surface and at least 2 feet higher

than any part of the building within 10 feet. Vent stack

shall be at least five feet in vertical height above the

drafthood outlet. The vent cap location shall have a

minimum clearance of 4 feet horizontally from, and in no

case below, unless a 4-foot horizontal distance is main-

tained, from electric meters, gas meters regulators and

relief equipment.

The weight of the vent stack or chimney must not rest on

heater draft hood. Support must be provided in compli-

ance with applicable codes. The heater top and draft

hood must be readily removable for maintenance and

inspection. Vent pipe should be adequately supported to

maintain proper clearances from combustible construc-

tion.

Type "B" double wall

or equivalent vent pipe

is recommended.

However single wall

metal vent pipe may

be used as specified

in the latest edition of

the National Flue Gas

Code ANSI Z 223.1

(Canada-CAN/CGA-

B149.1 and B149.2).

Gas piping must have a

sediment trap ahead of

the heater gas controls,

and a manual shut-off

valve located outside the

heater jacket. All gas

piping should be tested

after installation in ac-

cordance with local

codes.

Fig. #RP 8090.0

Fig. # 9469

WARNING: Indoor boilers require a drafthood that

must be connected to a vent pipe and properly vented

to the outside. Failure to follow this procedure can

cause fire or fatal carbon monoxide poisoning.

Optional Raypak D-2

Power Vent

Power Vent Kit

Model Part No.

185

008086

265

008086

335

008087

405

008087

CAUTION:

The heater and its manual shut off valve

must be disconnected from the gas supply during any

pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 KPA). Dissipate test pressure

in the gas supply line before reconnecting the heater

and its manual shut off valve to gas supply line.

FAILURE TO FOLLOW THIS PROCEDURE MAY

DAMAGE THE GAS VALVE. OVER PRESSURED

GAS VALVES ARE NOT COVERED BY

WARRANTY. The heater and its gas connections shall

be leak tested before placing the appliance in

operation. Use soapy water for leak test. DO NOT use

open flame.