Using flexible vent components – Napoleon Fireplaces DIRECT VENT MILLIVOLT SYSTEM BGD42N User Manual

Page 14

14

W415-0533 / E / 02.09.06

AIR

TERMINAL

CONNECTOR

INNER FLEX

LINER

OUTER FLEX

LINER

INNER

SLEEVE

HIGH

TEMPERATURE

SEALANT

ROOF SUPPORT

FIGURE 18

A VENT SHIELD MUST BE USED IF THE WALL TERMINAL IS

INSTALLED ON COMBUSTIBLE, EXTERIOR SURFACES.

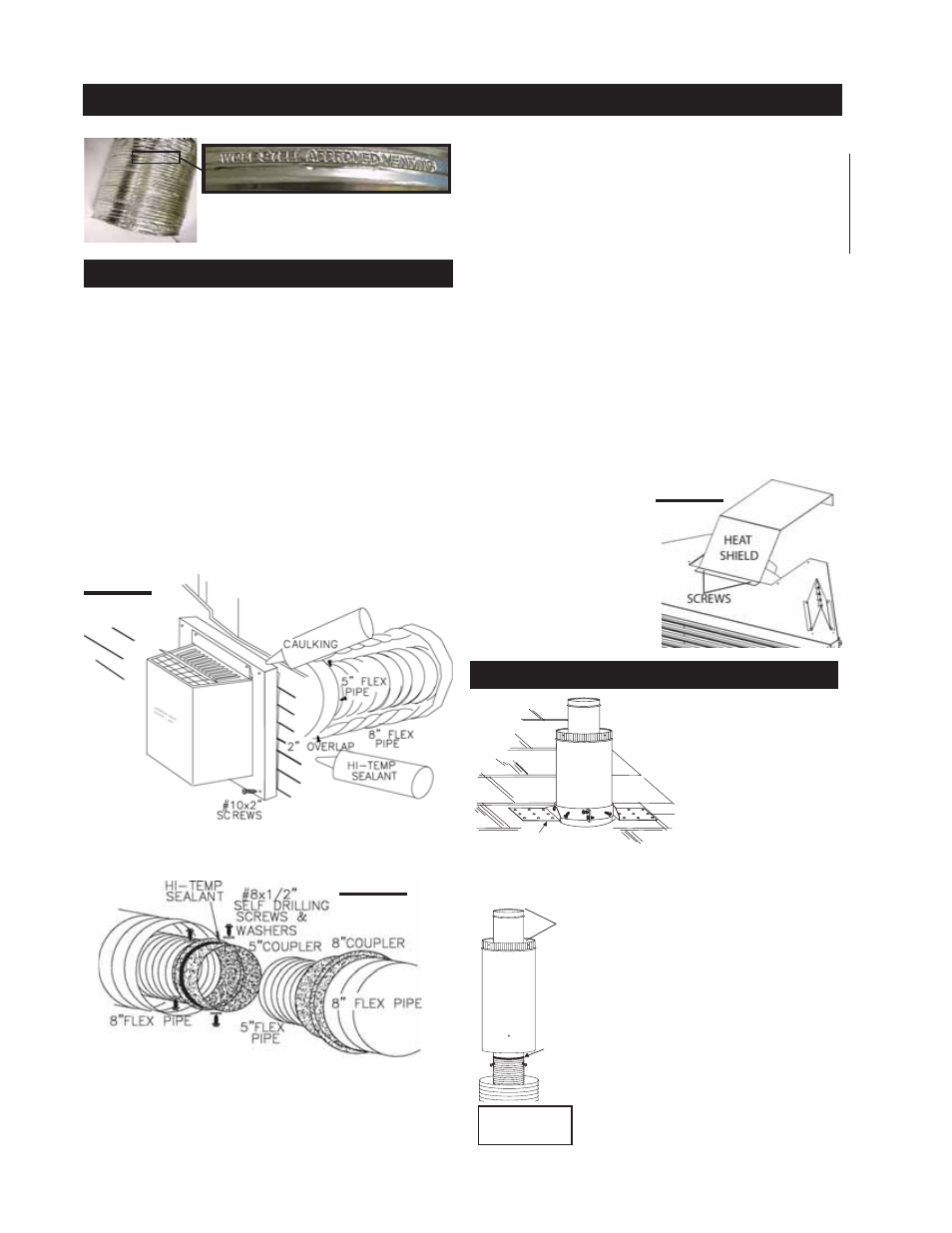

1. Cut or frame a hole in an exterior wall with a minimum

round or square opening of 10½ inches. Secure the firestop

spacer over the opening to the interior wall.

2. Stretch the 5" diameter aluminum flexible liner to the

required length taking into account the additional length

needed for the finished wall surface. Slip the liner a mini-

mum of 2" over the inner sleeve of the air terminal and

secure with 3 #8 screws. Apply a heavy bead of the high

temperature sealant.

3. Using the 8" diameter flexible aluminum liner, slide

over the outer combustion air sleeve of the air terminal and

secure with 3 #8 screws. Seal as before.

The air terminal mounting plate may be recessed into

the exterior wall or siding by 1½", the depth of the return

flange.

5. Apply a heavy bead of the high temperature sealant,

Mill Pac, to the inside of the 5" liner approximately 1" from

the end. Slip the liner a minimum of 2" over the fireplace

vent collar and secure with 3 #8 screws.

6. Using the 8" diameter flexible aluminium liner, apply

sealant, slide a minimum of 2" over the fireplace combus-

tion air collar and secure with 3 #8 screws.

7. If more liner needs to be used to reach the fireplace,

couple them together as illustrated. The vent system must

be supported approximately every 3 feet for both vertical

and horizontal runs. Use noncombustible strapping to

maintain the minimum 1" clearance to combustibles.

8. The heat shield must

be installed only when ter-

minating horizontally with

no vertical rise. Remove

the two screws nearest

the vent collars on the top

of the fireplace. Align the

vent shield (supplied) and

secure.

FIGURE 19

1. Fasten the roof support to the

roof using the screws provided.

The roof support is optional. In

this case the venting is to be

adequately supported

using either an alternate

method suitable to the

authority having

jurisdiction or the optional

r o o f

support.

2. Stretch the inner aluminum flex liner to the required

length. Slip the liner a minimum of 2” over the inner

sleeve of the air terminal connector

and secure with 3 #8 screws. Seal

using a heavy bead of the high

temperature sealant.

3. Repeat using the outer aluminum flex

liner.

4. Thread the air terminal connector /

liner assembly down through the roof.

The air terminal must be located

vertically and plumb. Attach the air

terminal connector to the roof support,

ensuring that the top of the air terminal

is 16” above the highest point that it

penetrates the roof.

HORIZONTAL AIR TERMINAL INSTALLATION

VERTICAL AIR TERMINAL INSTALLATION

4. Insert the liners through the firestop maintaining the

required clearance to combustibles. Holding the air termi-

nal (lettering in an upright, readable position), secure to

the exterior wall and make weather tight by sealing with

caulking (not supplied).

FIGURE 20

Use only approved aluminum flexible liner kits marked:

"Wolf Steel Approved Venting" as

identified by the stamp only on the 7”

outer liner.

USING FLEXIBLE VENT COMPONENTS

For safe and proper operation of the fireplace, follow the

venting instructions exactly.

All inner exhaust and outer intake vent pipe joints may

be sealed using either Red RTV high temp silicone seal-

ant or Black high temp Mill Pac with the exception of the

fireplace exhaust flue collar which must be sealed us-

ing Mill Pac (not supplied).

DO NOT CLAMP

THE FLEXIBLE

ALUMINUM LINER