Nordyne Forced Air Gas and Oil Furnace M1M User Manual

Page 4

4

necessary to correct problems due to improper

setup, improper installation, furnace adjust-

ments, improper operating procedure on the

part of the user, etc.

Some specific examples of service calls which

cannot be included in warranty payments are:

1. Converting the furnace to use another type

of gas.

2. Repairing duct work in the home found to be

faulty.

3. Correcting wiring problems in the electrical

circuit supplying the furnace.

4. Resetting circuit breakers, blown fuses or

other switches.

5. Correcting problems due to improper gas

supply pressure to the furnace.

6. Providing instructional training on how to

light and operate the furnace.

7. Furnace problems caused by installation of

an air conditioner, heat pump or other air

comfort devices.

8. Adding a Roof Jack extension because of

unusual wind and/or snow conditions.

9. Revising installation of the furnace flue as-

sembly (Roof Jack).

10. Adjusting or calibrating of thermostat.

11. Any construction debris which falls into flue

system.

Electrical Supply - 120 volts, 60HZ, 1 Ph.

Fuse or Breaker - 15 amps

Temperature Rise - 45° to 75°F

High Altitude - See Table 11. For Canadian

High Altitude (2,000’ to 4,500’), reduce the

gas manifold pressure to 3.0” W.C. for

natural gas and to 8” W.C. for LP gas.

Thermostat Circuit - 24 volts, 60HZ, 30 vac

Normal Anticipator Setting - 0.4

Manifold Pressure - Natural Gas: 3.5” w.c.

LP Gas: 10” w.c.

*Blower capacity only - needs relay box for AC

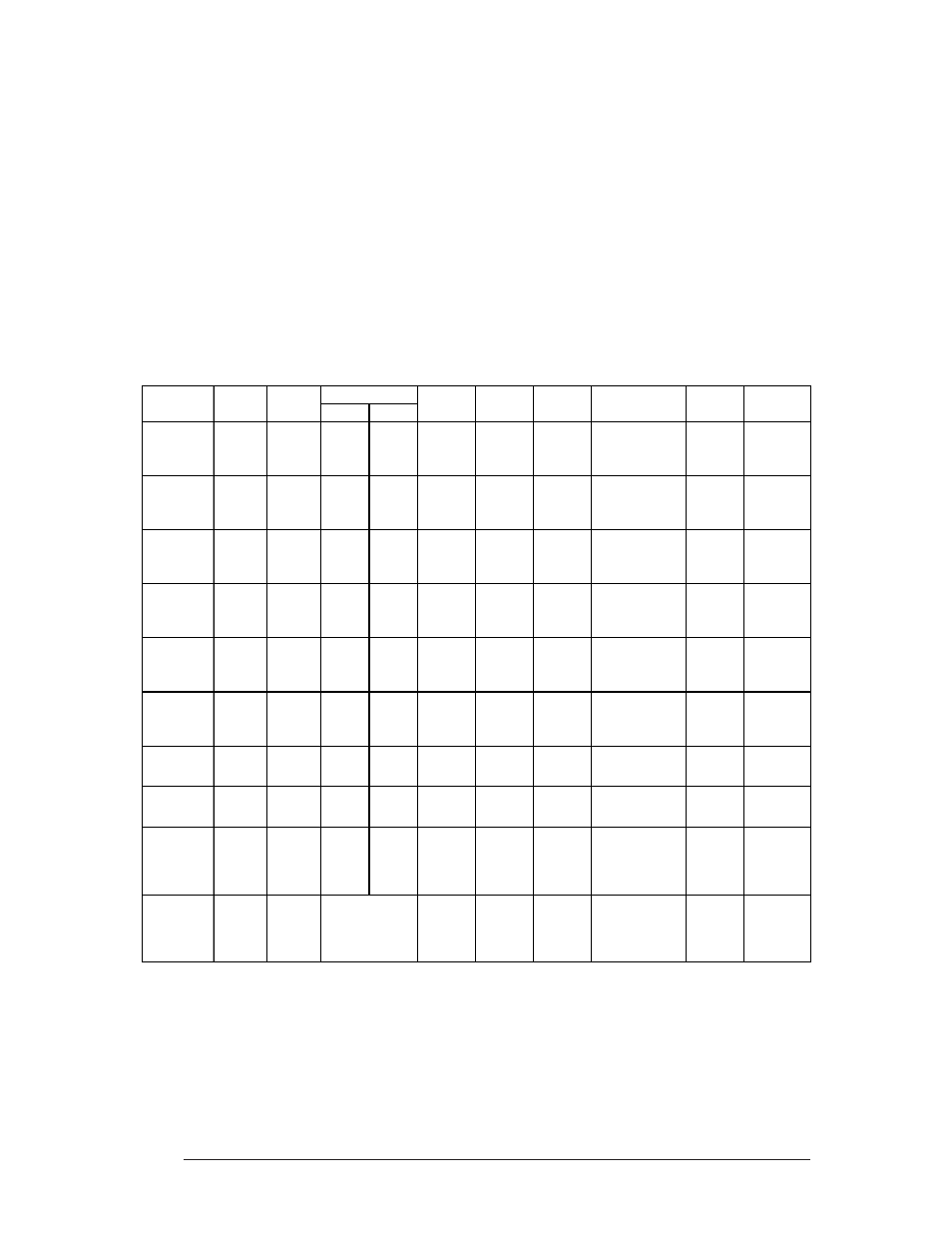

Table 2. M1 Furnace Specifications

Furnace

Input

Output

Orifice No

E.S.P.

Pilot

Ignitor

Comb.

Motor

A/C Ready

Model No

MBtu/h

MBtu/h

Nat.

LP

In WC

Burner

Direct

Blower

Hp

Tons

M1GH 056

56

45

29

45

0.3

x

1/8

2*

M1GB 056

56

45

29

45

0.3

x

1/4

3

M1GC 056

56

45

29

45

0.3

x

1/2

4

M1GD 056

56

45

29

45

0.3

x

3/4

5

M1GH 070

70

57

24

42

0.3

x

1/5

2½*

M1GB 070

70

57

24

42

0.3

x

1/4

3

M1GC 070

70

57

24

42

0.3

x

1/2

4

M1GD 070

70

57

24

42

0.3

x

3/4

5

M1GH 077

77

62

21

40

0.3

x

x

1/4

3*

M1GB 077

77

62

21

40

0.3

x

x

1/4

3

M1GC 077

77

62

21

40

0.3

x

x

1/2

4

M1GD 077

77

62

21

40

0.3

x

x

3/4

5

M1GH 090

90

72

17

36

0.3

x

x

1/4

3*

M1GB 090

90

72

17

36

0.3

x

x

1/4

3

M1GC 090

90

72

17

36

0.3

x

x

1/2

4

M1GD 090

90

72

17

36

0.3

x

x

3/4

5

M1MA 056

56

46

29

45

0.3

x

x

1/8

2

M1MB 056

56

46

29

45

0.3

x

x

1/4

3

M1MC 056

56

46

29

45

0.3

x

x

1/2

4

M1MD 056

56

46

29

45

0.3

x

x

3/4

5

M1MA 070

70

57

24

42

0.3

x

x

1/5

2½

M1MB 070

70

57

24

42

0.3

x

x

1/4

3

M1MC 070

70

57

24

42

0.3

x

x

1/2

4

M1MD 070

70

57

24

42

0.3

x

x

3/4

5

M1MB 077

77

62

21

40

0.3

x

x

1/4

3

M1MC 077

77

62

21

40

0.3

x

x

1/2

4

M1MD 077

77

62

21

40

0.3

x

x

3/4

5

M1MB 090

90

72

17

36

0.3

x

x

1/4

3

M1MC 090

90

72

17

36

0.3

x

x

1/2

4

M1MD 090

90

72

17

36

0.3

x

x

3/4

5

M1BA 066

66

53

26

43

0.3

x

x

1/5

2½

M1BB 066

66

53

26

43

0.3

x

x

1/4

3

M1BC 066

66

53

26

43

0.3

x

x

1/2

4

M1BB 086

86

68

18

37

0.3

x

x

1/4

3

M1BC 086

86

68

18

37

0.3

x

x

1/2

4

M1SA 066

66

54

.50 Gph

0.3

x

1/5

2½

M1SB 066

66

54

.50 Gph

0.3

x

1/4

3

M1SC 066

66

54

.50 Gph

0.3

x

1/2

4

M1SB 086

86

71

.65 Gph

0.3

x

1/4

3

M1SC 086

86

71

.65 Gph

0.3

x

1/2

4

Burner Model

AF-10 Nozzle

Spray Angle

80° A