Nordyne Outdoor Heat Pump Two Stage Split System R-410A User Manual

Page 12

12

verify system operation and compatibility with the

heat pump. Refer to the installation instructions

for this equipment and perform a functional

checkout in accordance with the manufacturer’s

instructions.

Indoor Blower

1. Turn the fan mode to ON. Verify that the

indoor blower is operating and that airfl ow is

not restricted.

2. Set the fan mode back to AUTO. Blower will

operate at a decreased speed on continuous

fan.

Short Cycle Protection

1. With the system operating in COOLING mode,

record the setpoint temperature setting of the

thermostat.

2. Gradually raise the setpoint temperature

until the outdoor unit and indoor blower de-

energize.

3. Immediately lower the setpoint temperature of

the thermostat to its original setting and verify

that the indoor blower is energized and that

the outdoor unit remains de-energized.

4. After approximately 3 minutes, verify that the

outdoor unit energizes and the temperature

of the air supplied to the facility is cooler than

ambient temperature.

Defrost Cycle Control

The defrost cycle is controlled by an Adaptive

Demand Defrost algorithm that monitors coil

temperature and ambient temperature. Other

features of the of the demand defrost board

include:

• 4 Field selectable defrost termination

temperatures (50° F - 80° F coil temperature).

• Field selectable compressor delay feature.

• High pressure and low pressure switches.

• Sensing of second stage compressor demand.

• Test/speed up capability.

• Anti short cycle timer (3 minutes) for

compressor protection.

• On board diagnostics with fl ashing LED for

quicker troubleshooting. See Table 2.

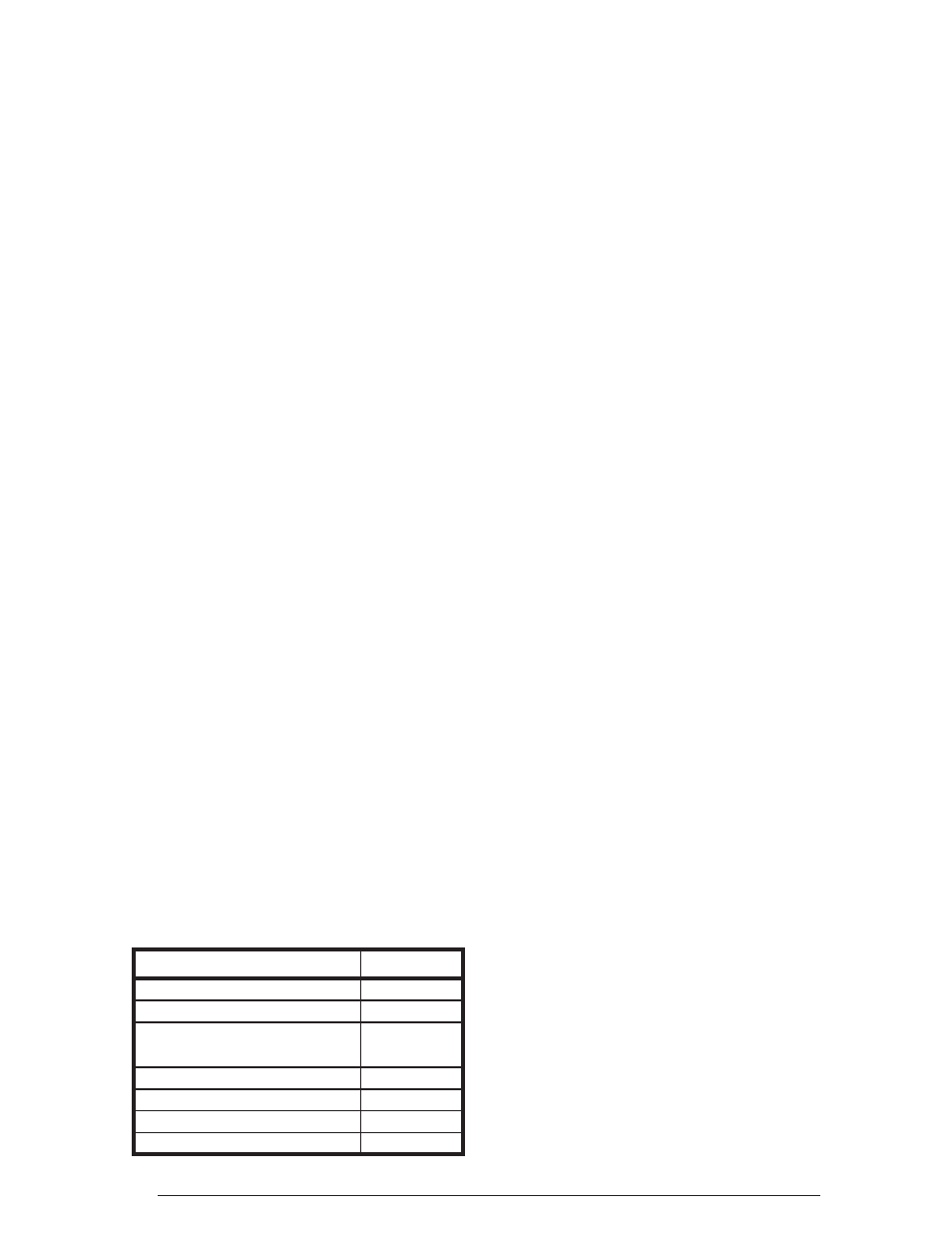

Diagnostic Description

LED Status

Control Fault (No Power)

Off

Normal Operation

On

ASCD Delay Active

(with compressor demand)

1 Flash

Low Pressure Switch Lockout

2 Flashes

High Pressure Switch Lockout

3 Flashes

Ambient Sensor Fault

4 Flashes

Coil Sensor Fault

5 Flashes

Table 2. Control Diagnostic

Control is uncalibrated when power is applied.

Calibration occurs after a defrost cycle. The

control initiates this sacrifi cial defrost after 34

minutes of accumulated compressor run time in

heating with coil temperature below 35° F. The

defrost cycle terminates if coil sensor reaches

selected termination temperature or after 14

minutes defrost.

Defrost function is disabled if coil temperature

is above 35° F. If Ambient sensor is detected as

open or shorted, demand defrost will not operate

and control will revert to time/temperature defrost

operation. If the outdoor coil sensor is detected

as open or shorted, the control will not perform

demand or time/temperature defrost operation.

NOTE: When the defrost cycle initiates, there

will be a 30 second compressor delay going into

and out of the defrost cycle. This delay may be

removed by removing P6 connector on the board.

This 2-stage unit will defrost in second stage

regardless of the stage called for by the

thermostat.

NOTE: All units are shipped from the factory with

the default termination temperature set at 70° F.

Defrost Test Procedure

1. Terminals R - C must have 18-30VAC present

between them in order for defrost sequences

to be initiated.

2 With heat mode thermostat demand (Y

connected to R), short and hold the TEST

pins together. This will energize reversing

valve to initiate a forced defrost. NOTE: This

will bypass the ASCD and allow the high stage

compressor to come on immediately (if the

REMOVE FOR NO DELAY jumper at P6 is

removed). If the REMOVE FOR NO DELAY

jumper at P6 is installed, the compressor will

energize immediately following a 30-second

delay.

3. Remove the short on the TEST pins.

• If the Coil temperature is above the Terminate

Temperature selection setting, the defrost

cycle will be terminated (reversing valve will

de-energized).

• If the coil temperature is below the Terminate

Temperature election setting, the defrost

cycle will continue for 14 minutes or until the

coil temperature rises above the Terminate

Temperature selection setting. NOTE: Short

the TEST pins for 1 second or more to force

the control out of defrost and back to heating

mode (reversing valve de-energized).

Compressor will turn on immediately (if

the REMOVE FOR NO DELAY jumper is

removed).