Insert vent connection chimney connection – Napoleon Fireplaces GDIZC-N User Manual

Page 6

6

W415-0223 / E / 03.05.09

2" OVERLAP

EXHAUST

SEALANT

HI-TEMP

INTAKE

VENT

CONNECTION

ASSEMBLY

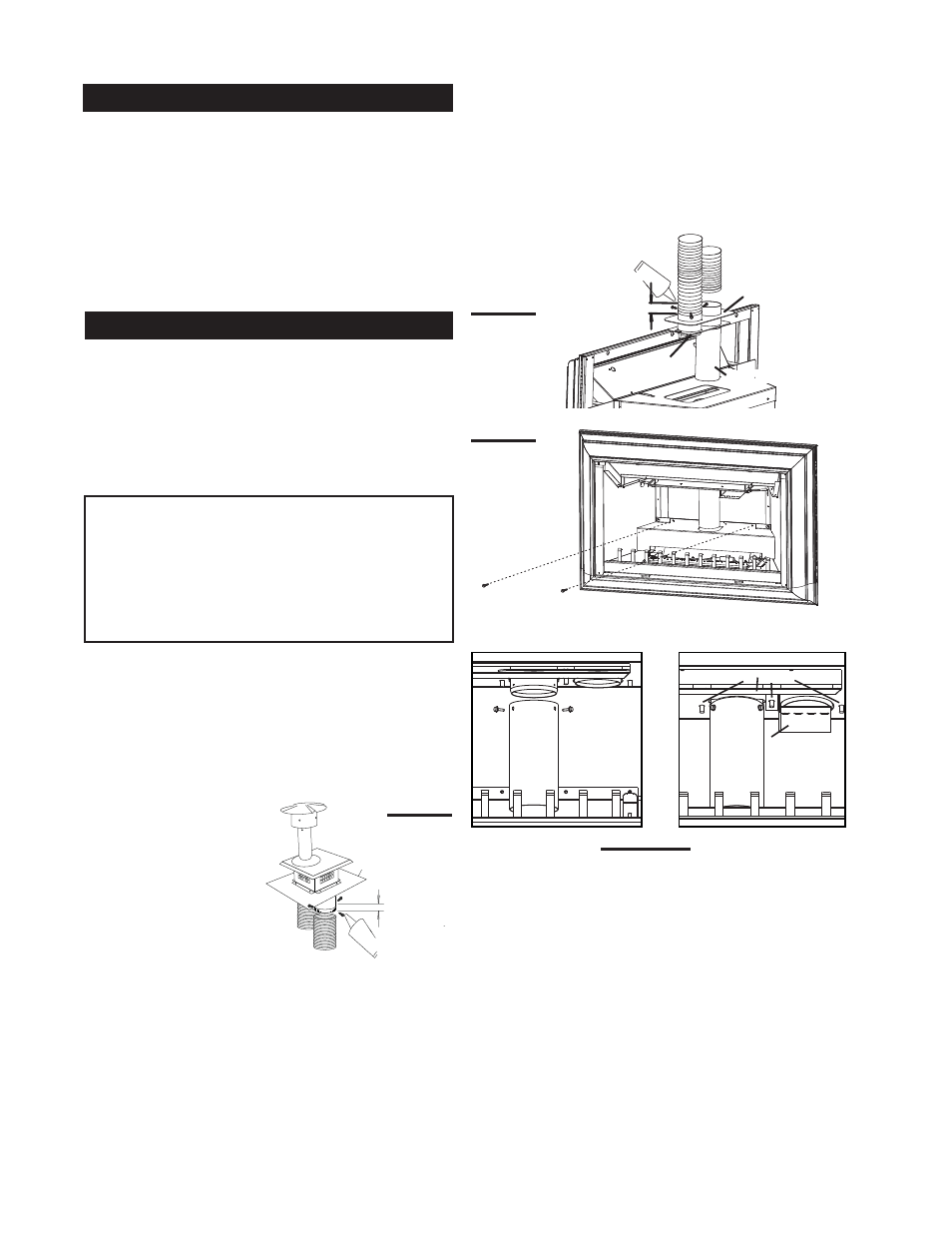

Move the insert close to its fi nal position inside the wood-

burning fi replace. This unit is equipped with 6 levelling screws

located as follows: two are on either side of the circulation

blower on the rear panel; four are located front and back on

either side beneath the log support. Level using four of the lev-

elling screws. See Figure 1a. Levelling the unit will eliminate

rocking or excessive noise when the fan is in operation. Once

the unit is level, move it partially into place within the fi replace

to allow for all connections to be made. It is not practical to

level the insert once the it has been installed. Determine the

required depth prior to installing the unit and adjust the four

levelling screws accordingly.

Chimney installation must conform to both national and local

code requirements. The chimney must be lined with one 2"

or 3" diameter liner for intake and one 3" diameter liner for

exhaust. The minimum and maximum vent lengths are 10 and

35 feet respectively. Recommended Napoleon kits come in 3

lengths: While the liners must be continuous from the fi replace

to the terminal, to achieve the needed length, they may be

coupled, using an aluminium coupler, provided installation is

sealed & secured.

We recommend that exhaust vents that pass through un-

heated spaces, such as a garage or attic, be wrapped in a

protective sleeve to minimize condensation and reverse fl ow

symptoms. See Trouble Shooting for details.

This unit is approved for use with a 2" liner for air intake and

a 3" liner for exhaust. For best performance, however, it is

recommended to use two 3" liners.

If a 2" liner is used for the intake, it is necessary to adjust the

primary air shutter. See "Air Shutter Settings" on page 11.

1. OUTSIDE: Slip one

end of a liner a minimum of

2" over one of the collars of

the terminal. Secure using

3 screws. Then seal the

joint and screw heads with

high temperature seal-

ant. Repeat with the other

liner.

NOTE: We recommend that the other end of the exhaust liner

be marked to eliminate the exhaust liner being connected to

the intake collar at the unit.

FIGURE 3

4. Detach the two screws from the back of the fi rebox and

remove the panel, as illustrated.

5. Reaching in through the insert, manoeuvre the vent con-

nection assembly through the openings in the fi rebox top,

taking care not to damage the gasket. In case of a low ceiling

fi replace, the extension should be removed and reinstalled

after the vent connection is secured to the fi rebox. Attach the

restrictor plate to the centre stud and secure the assembly

using the three studs and ¼-20 hex nuts.

INSERT VENT CONNECTION

CHIMNEY CONNECTION

FIGURE 4

FIGURE5a-b

1-2" & 1-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST

&

2-3" TO 2" REDUCER:

GDI-2320KT

VENT KIT 20FT

GDI-2325KT

VENT KIT 25FT

GDI-2335KT

VENT KIT 35FT

2-3" DOUBLE PLY ALUMINUM LINER-INLET AND EXHAUST:

GDI-320KT

VENT KIT 20FT

GDI-325KT

VENT KIT 25 FT

GDI-335KT

VENT KIT 35 FT

2. Gently stretch the liners to the required lengths and in-

sert into the chimney. Place the terminal onto the top of the

chimney cap and fi t the fl ashing plate to suit. Make weather

tight by sealing with caulking (not supplied) and fasten to the

chimney with screws and plugs (not supplied)

3. INSIDE: Attach and secure the fl ex liners to the vent

connection assembly using the same procedure as before,

ensuring that the marked exhaust liner is attached to the

exhaust collar.

EXHAUST

COLLAR LABELED

INTAKE

OVERLAP

SEALANT

HI-TEMP

FLASHING

PLATE

2"

TERMINAL

GDI-223

FIGURE 2

RESTRICTOR

PLATE

STUDS

VENT

CONNECTOR

EXTENSION