Table adjustments – Powermatic 201HH User Manual

Page 15

15

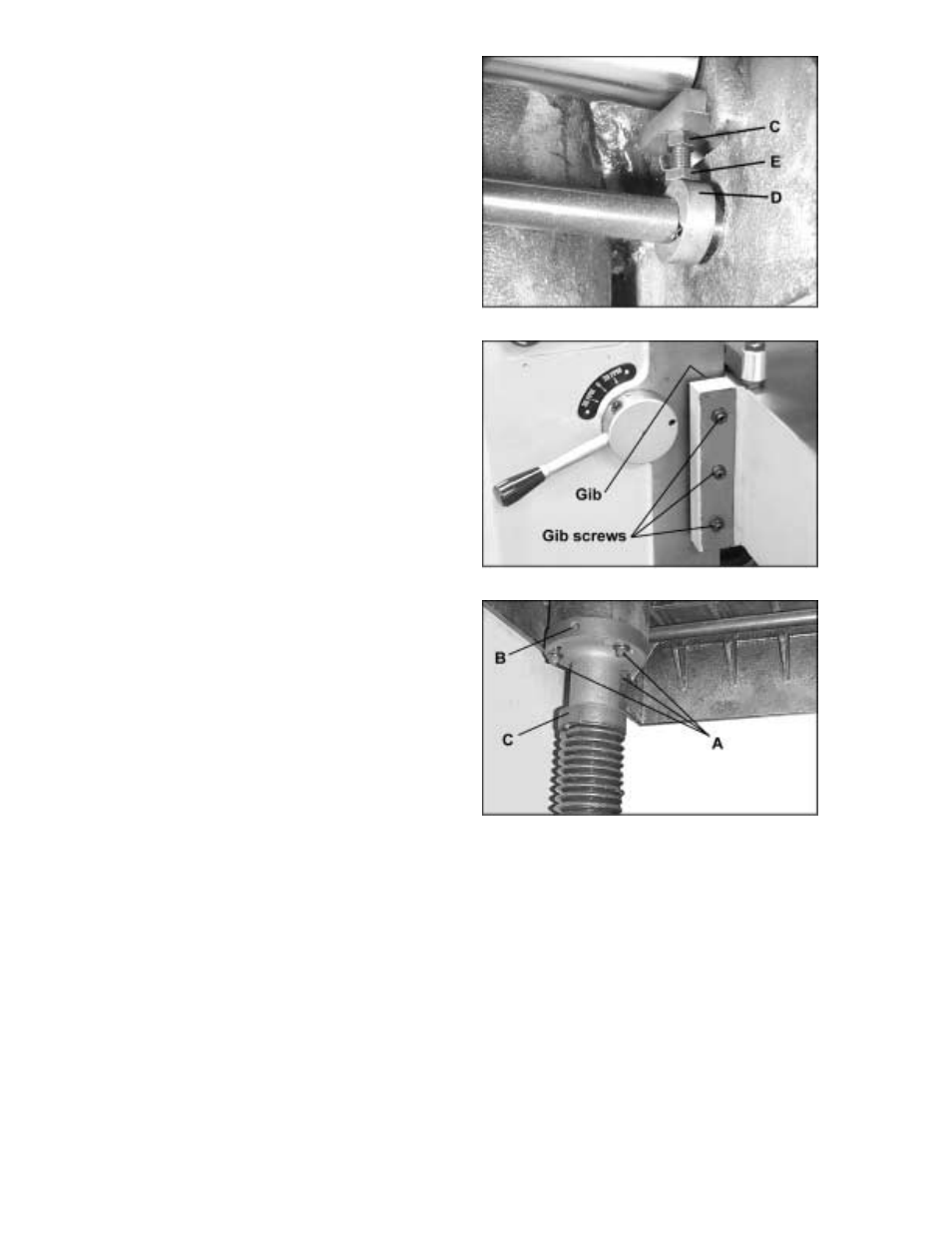

5. If

the

gauge reading is greater or less tha n

zero, reach beneath the table with a wrenc h

and loosen the hex nut (C, Figure 17) whic h

is above the cam (D, Figure 17) near the

end of the roller that needs adjusting. Rotate

the hex cap screw (E, Figure 17) until the

gauge reads zero.

6. Repeat the process for the left side of the

table roller, and then re-check the right side.

It is important that both ends of the table

roller be the same height to help prevent

skewing of the board as it feeds through the

machine.

7. Re-tighten the hex nuts (C, Figure 17) on

both ends of the table roller.

8. Repeat the procedure for the second table

roller.

Table Adjustments

The planer table is raised and lowered by twin

screws supported on bearings, and is guided by

machined surfaces on the side panels. The fit-

up to prevent the table from rocking is controlled

by two gibs in front. See Figure 18. These gibs

are pre-set at the factory and require no

attention. If, after extensive use of the planer,

some looseness in the table develops, these

gibs can be adjusted individually using the gib

screws provided so that the ways are lightly

contacting on all four surfaces. The gibs should

be tight enough to prevent rocking or movement

of the table when the planer is in operation.

To perform accurate planing, the table must be

parallel with the cutterhead. Lack of parallelism

results in a taper over the width of the board. To

check parallelism do the following:

1. Place a gauge on the table and contacting a

knife at the apex of its arc. Do this at each

end of the cutterhead and compare the

measurements.

2. If the table is not parallel to the cutterhead,

place the gauge at the end that needs to be

raised.

3. Loosen the three socket head cap screws

(A, Figure 19) beneath the table.

4. Place a rod-like object (such as a hex

wrench) into one of the open holes (B,

Figure 19) and turn the shaft (C, Figure 19)

to raise the table until the gauge reads the

proper measurement. Or, the same effect

can be achieved by lowering the other side

of the table.

5. Re-tighten the screws (A, Figure 19).

NOTE: This adjustment may generate the need

to recalibrate the table height pointer.

Figure 17

Figure 18

Figure 19