Powermatic 201HH User Manual

Page 13

13

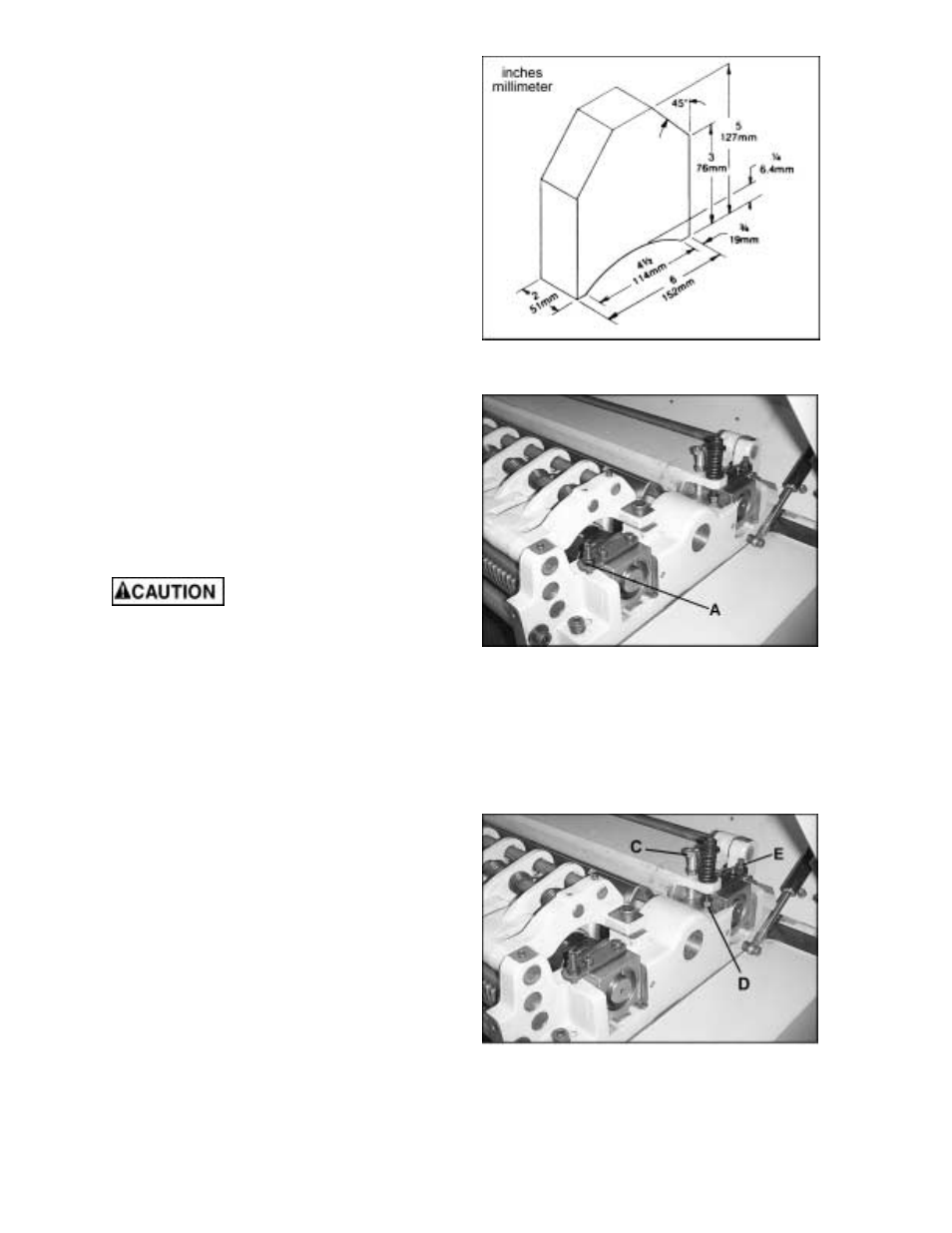

6. If it is not 1/16” below the knife, correct by

loosening the hex nut and turning the

adjustment screw (A, Figure 14) with a hex

wrench.

7. Move the gauge to the extreme right end of

the infeed roller and check. Make similar

adjustments if needed.

8. Tighten hex nuts (A, Figure 14) whe n

finished.

IMPORTANT: The setting on both ends of the

infeed roller must be the same to avoid skewing

of the material as it is fed through the machine.

Chipbreaker

The chipbreaker is a sectionalized type made of

spring-loaded sections mounted on a bar, which

complements the sectional infeed roller. The

functions of the chipbreaker are to break chips

into small pieces, help avoid splintering of the

wood, help avoid board bounce on thinner

boards, to direct the flow of chips out of the

machine, and to permit multiple board surfacing.

The chipbreaker has been factory set at 1/32”

(0.8mm) below the cutting arc of the knives, and

has been spring-tensioned properly.

A chipbreaker set too low or

with excessive tension may prevent stock

from feeding into the machine.

Pressure Bar

Most planing problems can be traced to

improper setting of the pressure bar. Its functio n

is to hold down the material after it passes under

the cutterhead and throughout the remainder of

the cut. Its basic setting is to be in line with the

arc of the cutterhead knives.

If the pressure bar is too high, a shallow "clip"

will occur at each end of the board. If it is too

low, stock will not feed through.

Use a gauge to set the full length of the

pressure bar to be .000-.001" (.02mm) below

the arc of the cutterhead.

Figure 15 shows the height adjustment screw

(C) and the spring tension adjustment screw (D)

for the pressure bar. Loosen the hex nut and

rotate the screw as needed. Make sure the

setting on both ends of the pressure bar is the

same. Tighten the hex nuts when adjustment is

complete.

This initial setup is a starting point and final

adjustment may have to be made during a test

cut.

Figure 13

User-made Gauge Block

Figure 14

Figure 15