Receiving, Installation & assembly – Powermatic 31A User Manual

Page 8

8

RECEIVING

Remove the sander and base and any loose parts from

their containers. Check for damage and ensure all parts

are intact. Any damage should be reported to your

distributor and shipping agent immediately upon

discovery. Before proceeding with assembly, read the

manual thoroughly; familiarize yourself with correct

assembly and maintenance procedures and proper

safety precautions.

Contents of crate:

1 base assembly with motor

1 sander body

1 abrasive belt

1 abrasive disc

1 fence assembly

1 hardware bag

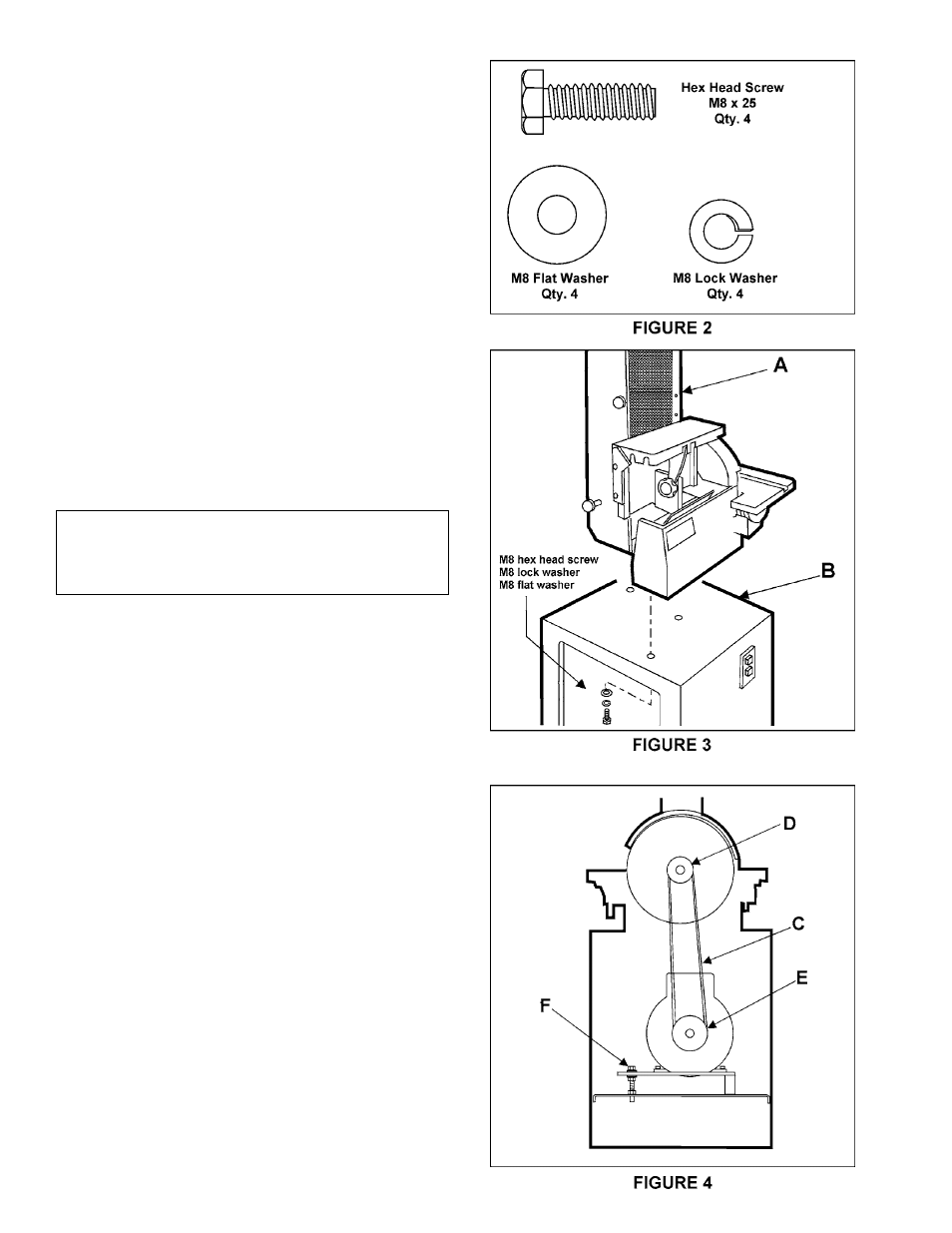

The contents of the hardware bag are drawn in Figure 2.

INSTALLATION & ASSEMBLY

Tools required

adjustable wrench (or socket wrench set)

hex wrenches

1. If the machine is to be secured to the floor, use

high quality lag screws through the four holes inside the

bottom of the base. If using a mobile base, be sure to

lock the wheels before assembling, operating or making

adjustments to the sander. (A mobile base for your

sander is available from Powermatic – stock # 708221.)

2. Mount the sander body (A) to the stand (B) with

four M8 x 25 hex head screws, four M8 lock washers

and four M8 flat washers as shown in Figure 3.

3. The drive belt (C) is already mounted on the drive

sheave (D) behind the disc, as shown in Figure 4.

However, it should be checked to ensure that it is in the

sheave groove.

4. Position the belt (C) around the motor sheave (E)

and tension the belt by adjusting the nuts (F) on the

tensioning screw.

NOTE: Proper tension is achieved when there is

moderate deflection in the belt midway between the two

sheaves.

ELECTRICAL CONNECTIONS

Wire the sander in accordance with the requirements of

the National Electrical Code (ANSI/NFPA70). See wiring

diagram on pages 20-21. Make sure your power source

matches the rating on the machine’s motor nameplate.