Powermatic 31A User Manual

Page 10

10

3. Make final adjustments to the tracking by

momentarily starting and stopping the motor while at the

same time adjusting the tracking screw (F), Figure 5, at

the side of the belt arm. To lock the screw in place,

rotate the tracking screw locking nut (G) against the belt

arm.

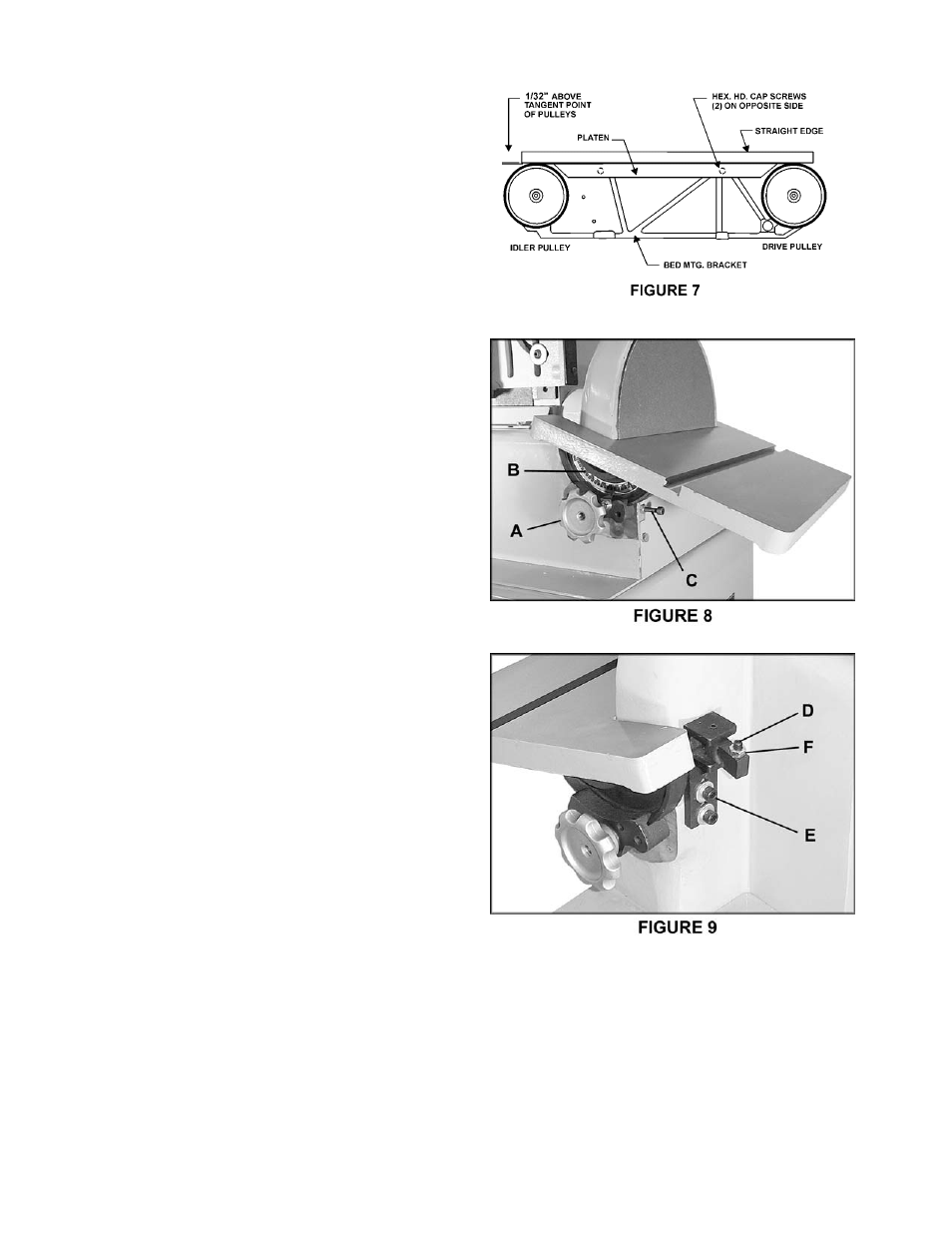

PLATEN ADJUSTMENT

Due to wear, occasionally the platen may have to be

readjusted. To do this, proceed as follows:

Swing the end guard out of position and remove the side

guard. Loosen the two hex screws (A) on the opposite

side of the belt arm and adjust the platen. See Figure 7.

The platen should be 1/32” to 1/16” above the tangent

points of the pulleys and in contact with the belt at both

ends. A straight edge can be used with the belt to align

the platen.

SANDING TABLE ADJUSTMENT

The sanding table may be adjusted from any angle from

15 degrees up to 45 degrees down. To adjust, loosen the

lock wheels (A) on both sides and pivot table to the

desired angle as shown on the trunnion scale (B). Re-

tighten the lock wheel (A). See Figure 8.

A 45-degree stop (C) is located under the table. Check

the angle of the table against the stop to make sure it is

45 degrees. If it is not, adjust by loosening the hex nut

and screwing the stop in or out as needed. Re-tighten

hex nut.

A zero-degree stop (D) is located behind the disc. See

Figure 9. The block should be set for quick placement of

the table to the 0 position (90 degree table). The block

must be swung out of position for the table to be tilted

downward. If major adjustment of the zero-degree stop is

necessary, loosen the socket head cap screws (E) to

raise or lower the bracket. For fine adjustment, loosen

the hex nut (F) and turn the screw in or out as needed.

Re-tighten hex nut (F).

Periodically check zero position on the table by using a

combination square. The angle between the table and

disk should be 90 degrees when the trunnion pointer is at

zero

WORK STOP

Your sander is equipped with a work stop for use with the

belt arm in the horizontal position (see Figure 17). When

installed, the work stop will prevent a work piece from

being thrown from the belt. If removed for through-

sanding, the work stop should be immediately reinstalled

after the through-sanding operation (unless the fence

attachment is used in its place for 45-degree or vertical