Python LIQUID COOLED MILLERMATIC COMPATIBLE 248-8XX User Manual

Page 19

Liquid Cooled Millermatic Compatible™ Python

®

Owner's Manual - Page 8

Disconnect Power

Before Troubleshooting.

Section E

Troubleshooting Guide

To aid in troubleshooting problems with your welding equipment, it is best

to understand the basic theory of operation for this Push-Pull System. The

slave motor in the feeder runs at a fast, constant speed, but has very low

torque. It is always trying to feed more wire than the gun motor wants,

and when the motor gets all it wants, it slows the slave motor, preventing

a bird’s nest. Because of the low torque produced by the slave motor, a

brake system is used to prevent wire overrun rather than tension. The drag

adjustment in the feeder is used simply to keep the wire slightly taut, so it will

not pull off the spool while feeding wire.

The high torque 24VDC gun motor is controlled by an electric speed

control located in the feeder, and a pot located in the gun. The gun motor,

potentiometer, and micro switch are connected to the cabinet/control box via

a control cable and connector. If this cable becomes damaged, a variety of

symptoms can occur, depending on which wire(s) break. To test, check each

wire for continuity and shorts.

Remember, the micro switch in the gun activates both the slave motor and

gun motor circuits in the cabinet. Therefore, if the slave motor and brake

solenoid operate, but the gun does not, look more toward the gun motor’s

24VDC circuits, speed control, control cable, or the gun motor. If nothing

operates, look more toward the slave motor’s input, micro switch leads, or

micro switch.

Testing The Gun

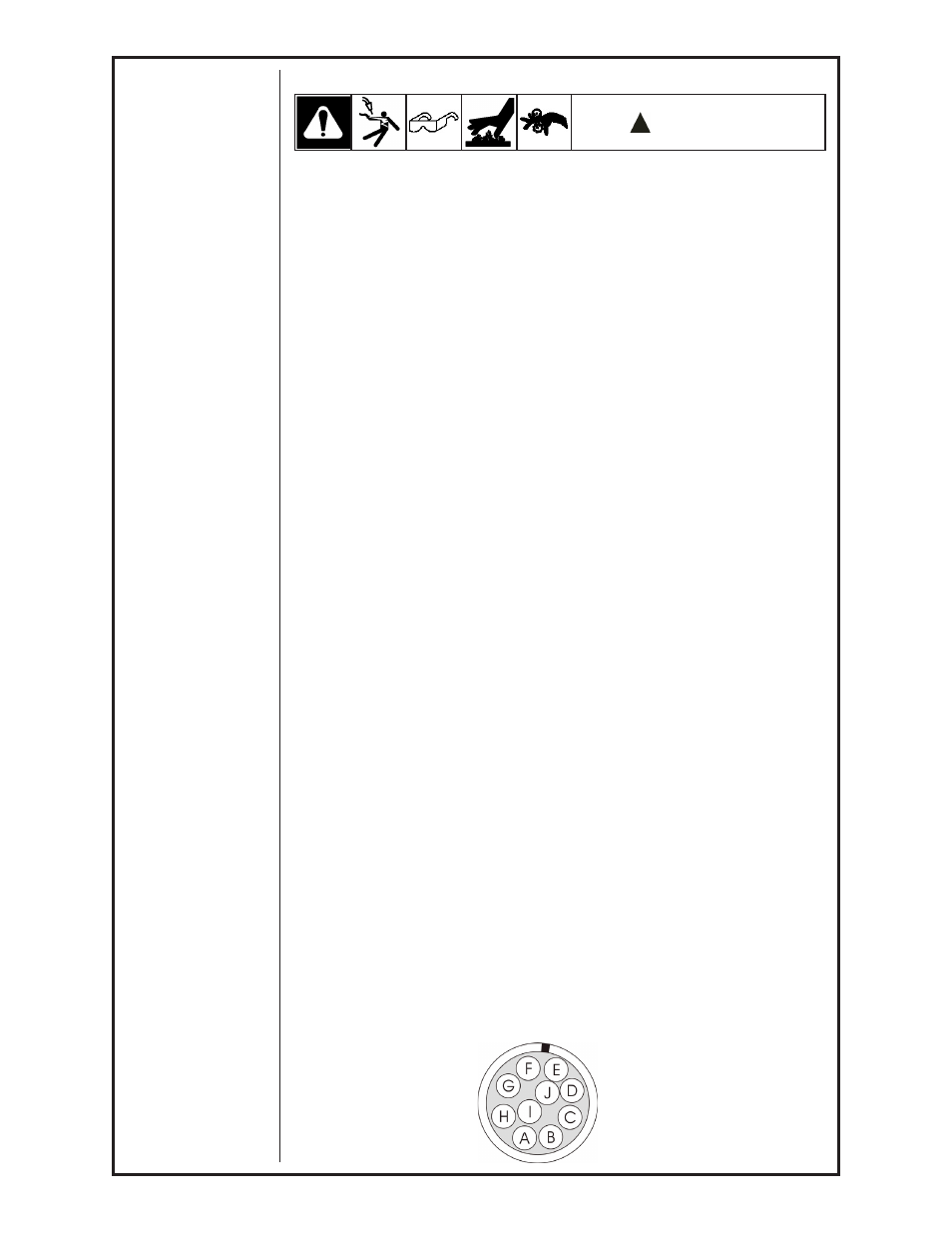

Reference the "X" clocked diagram

on the liquid cooled Millermatic Compatible™ Python

®

electrical diagram

for information about pin-outs and locations.

Motor Check

Remove the connector from the cabinet.

Using the connector, check the resistance across pins

“C” and “B” (motor

leads). The resistance across the motor should be between

5 - 10 ohms as

the potentiometer is turned.

If an open circuit or short exist, check the motor leads and motor

independently.

Testing the Gun Potentiometer

Using the connector, check the resistance across pin

“f” (wiper) and pin

“E”. The resistance should vary from 0 - 5K ohms as the potentiometer is

turned.

Check the resistance across pin

“f” (wiper) and pin “H”. The resistance

should vary from

5K - 0 ohms as the potentiometer is turned.

Testing the Micro Switch

Using the connector, check for continuity across pins

“D” and “G” when the

trigger is pressed.