Table parallelism, Table parallelism inspection, Adjusting table parallelism – Pioneer PNR 14-150 User Manual

Page 22

22

© 2006 Pioneer Supply International

22

© 2006 Pioneer Supply International

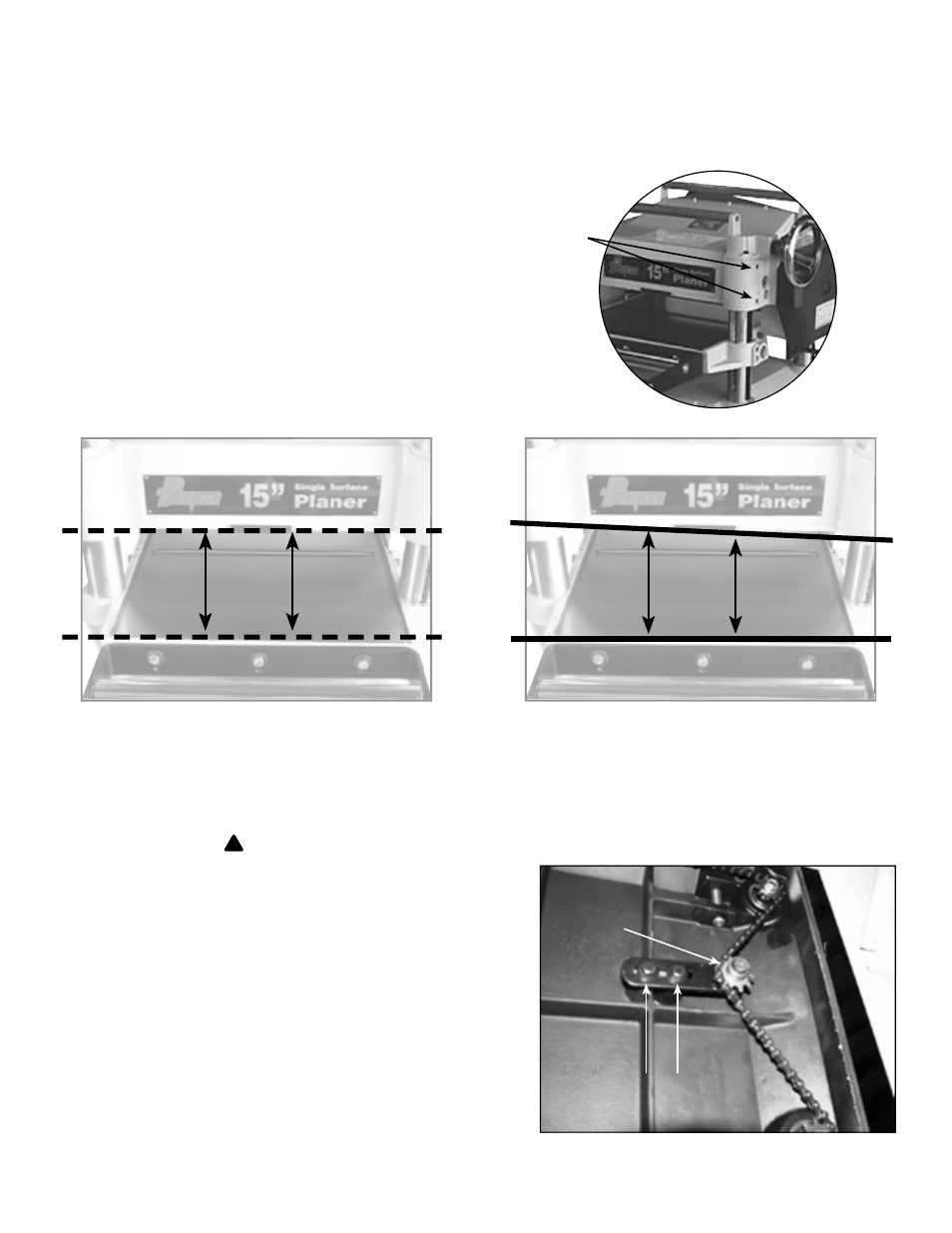

Table Parallelism

Your Pioneer planer is pre-set parallel at the factory and should rarely need adjustment. However, in the

instance that lumber is not parallel in width follow the adjustment procedures.

Table Parallelism Inspection

1 Disconnect from power source before performing

any adjustments.

2 Table parallelism adjustments less than .016”

(the difference in thickness from one side of the

board to the other)

3 Loosen the caps screws that hold the head cast-

ing in position. (Figure 32) Move the casting up

or down to the proper position and tighten. See

figure 33 and 34. Plane another test piece.

Adjusting Table Parallelism

If the variance is greater than .016” you will need to turn the column sprockets to adjust parallelism.

1 You first need to gain access to the sprockets by tilting the

planer on its side.

!

WARNING: The planer is very heavy

and should not be tilted by one person or by hand. Use

proper lifting methods.

2 Loosen the 2 bolts that hold the idler sprocket which

places tension on the chain. (Figure 35)

3 Remove the chain from the sprocket that needs to be

adjusted.

4 Turn this sprocket by hand either left or right depending on

which way the adjustment is needed. Adjust this sprocket

to be the same as the other 3. One tooth will usually be

enough to make the adjustment.

5 Turning the sprocket clockwise will reduce the distance

between the head casting and the table and turning the

sprocket counter-clockwise will increase this distance.

Idler

Sprocket

Lock Bolts

Figure 34

Not Correct Parallel

Correct Parallel

Figure 33

Cap Screws on

each Column

Figure 35

Figure 32