Patterson-Kelley MACH-05 User Manual

Page 17

MACH® Series

Gas-Fired Boiler

Installation

Page 13

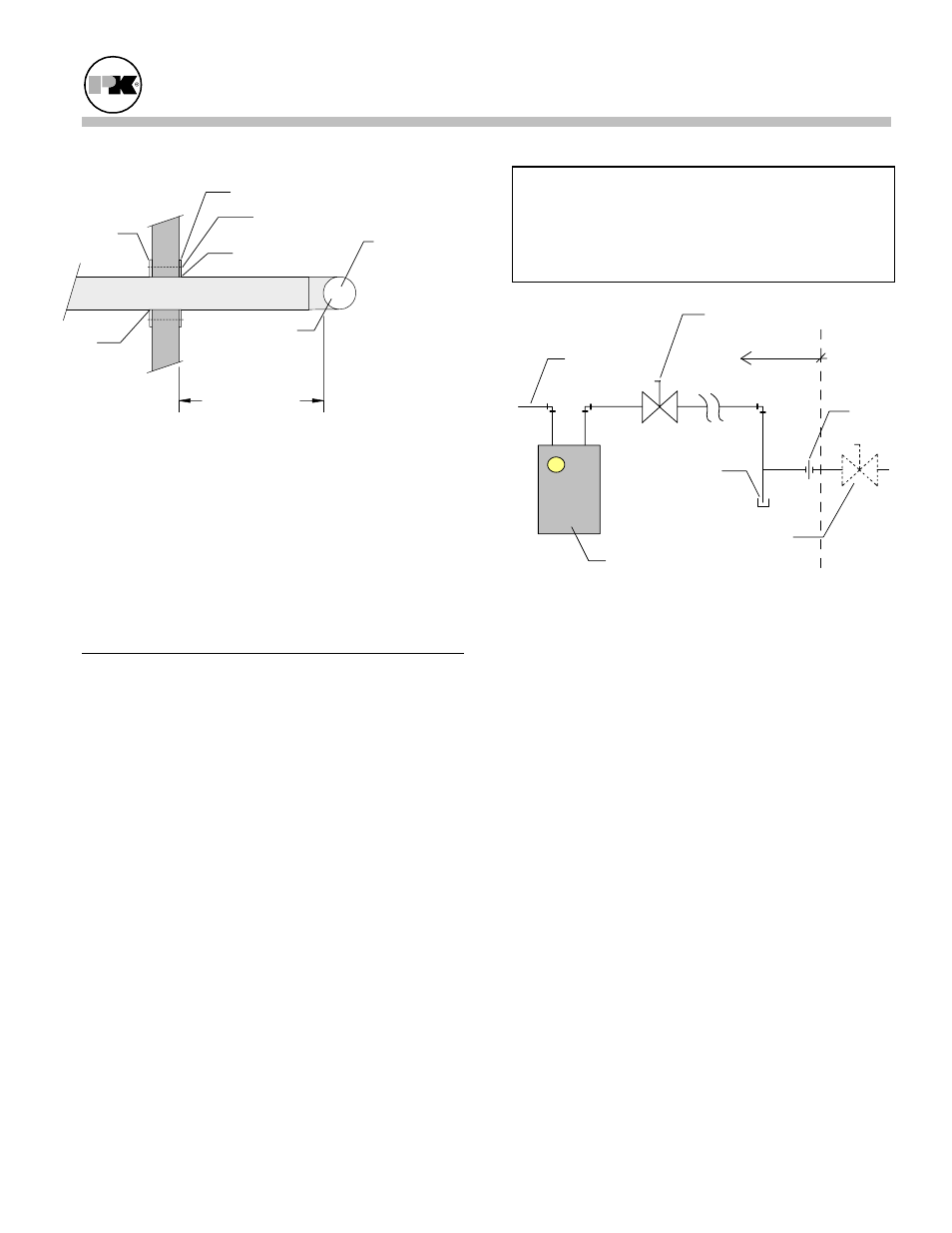

Intake Termination Details

3.6.13 Vent Elbows

The turn from horizontal to vertical should be made

with two 45º ells or with one long radius 90º ell for

best operation. Do not use "short radius" ells.

3.7

G

AS

P

IPING

Before making the gas hook-up, make sure the boiler

is being supplied with the type of fuel shown on the

boiler nameplate.

The boiler shall be installed such that the gas ignition

system components are protected from water

(dripping, spraying, rain, etc.) during appliance

operation and service (circulator replacement, control

replacement, etc.)

The boiler is factory fire-tested and adjusted for proper

combustion with natural gas supply pressure of 7”

W.C. Typical gas pressure supply for natural gas is

7" W.C. (11" W.C. for propane). The gas train

components are certified to handle a maximum inlet

pressure of 14" W.C. (1/2 psig.). If the available gas

pressure exceeds 14" W.C., a suitable additional

intermediate gas pressure regulator of the "lock up"

type must be provided to reduce the pressure to less

than 14" W.C.

WARNING!

All threaded connections must be made using a

pipe compound that is resistant to the action of

liquefied petroleum gases. Do not use Teflon

tape on gas line threads.

Gas Piping

In the Commonwealth of Massachusetts, the gas cock

must be a “T-handle type.”

Note: Install a sediment trap (drip leg) and a union

connection ahead of the primary manual shutoff valve

on the boiler. Gas piping should be installed in

accordance with National Fuel Gas Code, ANSI

Z223.1, latest edition, and any other local codes

which may apply; in Canada see CAN/CGA-B.149.

Note: See Pipe Capacity for Natural Gas chart on the

following page for required pipe size, based on

overall length of pipe from meter plus equivalent

length of all fittings. Approximate sizing may be

based on 1 cubic foot of natural gas per 1,000 Btu per

hour input, i.e., 500,000 Btu per hour requires about

500 cubic feet per hour. (See "Typical Boiler

Operating Conditions," Section 4.3, for more

information.)

Meter

(not supplied)

Shutoff

(on boiler)

Natural Gas

Supply

By Installer

Remote Gas Shutoff

(not supplied)

Union

Drip Leg

Field Provided

Inlet Screens

Recommended

Termination

Centering

Support Plate

Sealant

Outside Plate

Cover Plate

Fastener

Sealant

12" min.