Basic jointer operation – Powermatic 60HH User Manual

Page 22

22

Basic Jointer Operation

NOTE: If you are inexperienced at jointing, use

scrap pieces of lumber to check settings and get

the feel of operations before attempting regular

work.

This section briefly discusses general rules as

well as some of the basic cuts using a jointer,

such as surfacing, edging, beveling, skewing,

rabbeting and taper cuts.

Always use cutterhead guard

(except during rabbeting) and keep hands

away from cutterhead.

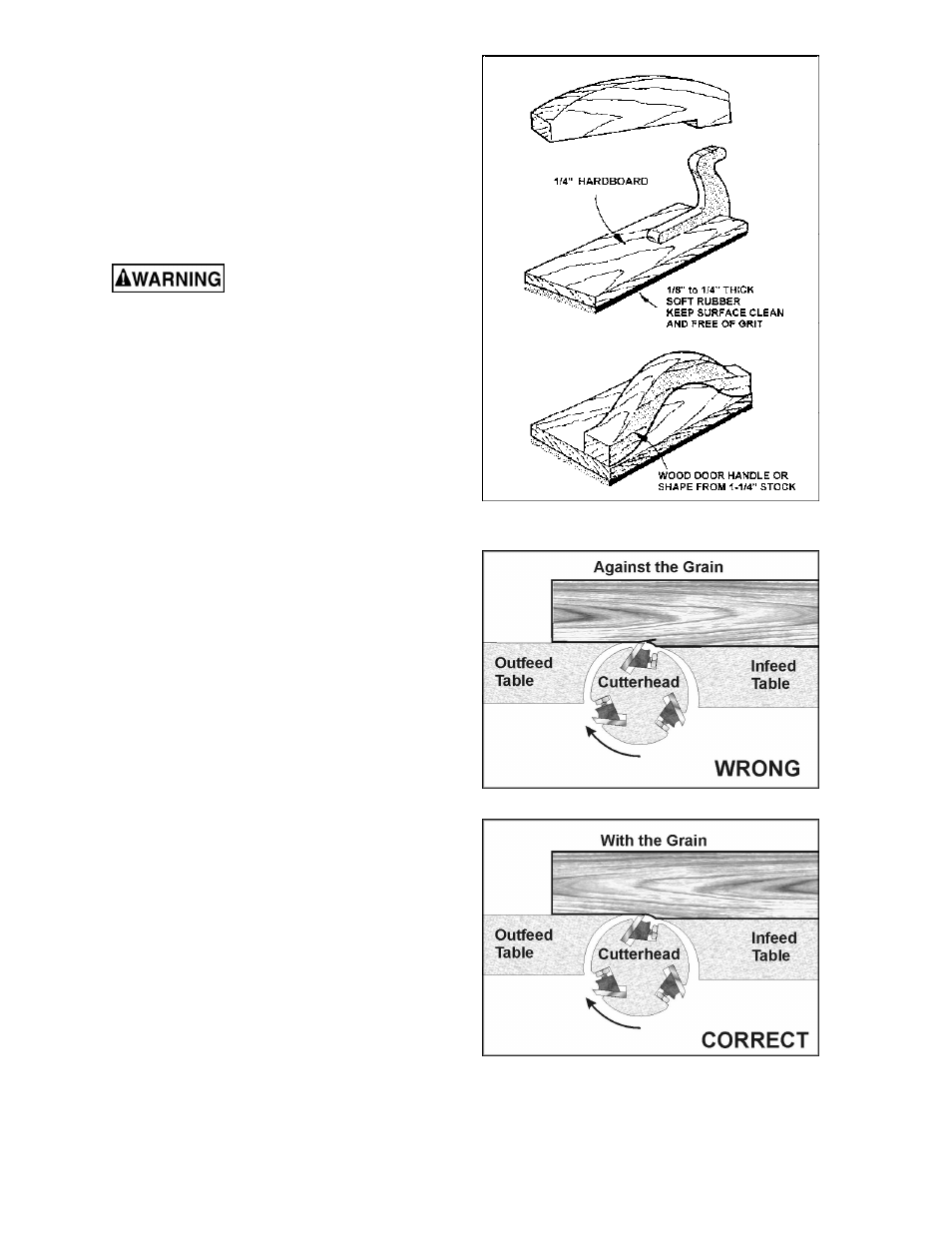

Jointing Short or Thin Work

When jointing short or thin pieces, use a push

pad or push block to eliminate all danger to the

hands. Two push blocks are included with your

jointer. Many users make their own push blocks

from scrap material to suit the particular job at

hand. Three examples are shown in Figure 31.

Direction of Grain

Avoid feeding work into the jointer against the

grain. This will result in chipped and splintered

edges (Figure 32). Feed with the grain to obtain

a smooth surface (Figure 33).

Hand Placement

At the start of the cut, the left hand holds the

work firmly against the infeed table and fence

while the right hand pushes the work toward the

knives. After the cut is under way, the new

surface rests firmly on the outfeed table. The left

hand should press down on this part, at the

same time maintaining flat contact with the

fence. The right hand presses the work forward

and before the right hand reaches the

cutterhead it is moved to the work on the

outfeed table. Follow the 3 inch rule. Never

pass hands directly over the cutterhead.

Surfacing

Jointing the face of stock, or surfacing, is shown

in Figure 34. The use of push blocks or pads will

help ensure against the operator's hands

coming into contact with the cutterhead in the

event of a kickback, or as the trailing end of the

board passes over the cutterhead.

Adjust the infeed table for depth of cut. Cuts of

approximately 1/16" at a time are

recommended, as this allows better control over

the material being surfaced. More passes can

then be made to reach the desired depth.

Figure 31

User-made pushblocks

Figure 32

Figure 33