Leveling tables – Powermatic 60HH User Manual

Page 17

17

Leveling Tables

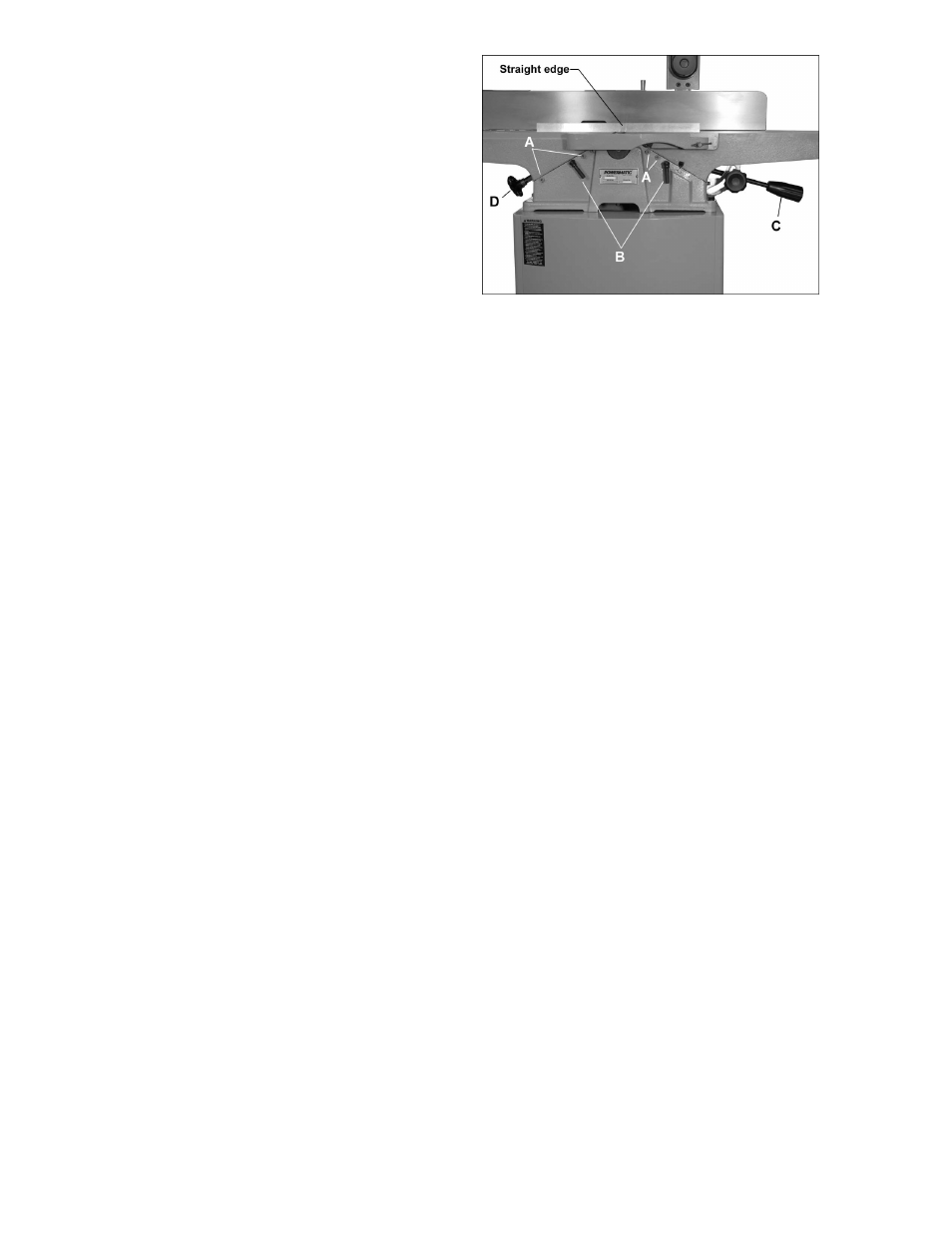

Refer to Figure 20.

The tables have been leveled with each other

from the factory, but this should be confirmed by

the user, and checked periodically, by placing a

steel straight edge across both tables. If tables

are not level, this may be the result of loose

gibs. Correct as follows:

1. Loosen hex nuts on the gib screws (A) with

a 12mm wrench, then loosen the gib screws

with a 4mm hex wrench. Loosen the table

lock handle (B).

2. Remove the lower hex nut and gib screw (A)

and check screw hole to make sure that

punch mark in the gib is aligned with the

screw hole. If punch mark is not visible, or it

does not line up with screw hole, use a

screwdriver to lightly tap the gib back into

alignment.

3. Re-install the lower gib screw (A) but do not

tighten.

4. Carefully tighten the table lock screw (B).

The table will begin to move toward the

straight edge.

5. When aligned, re-set the gib screws (A) until

tight. If table does not align with straight

edge, use the adjusting arm (C) for the

infeed table, or handwheel (D) for the

outfeed table, until the table is flush with the

straight edge.

6. Tighten the gib screws (A) then back them

off approximately 1/4 turn or until the table

moves freely, and re-set the lock nuts on the

gib screws.

If table will still not line up:

Remove gib screws (A, Figure 20) and table

locking handle (B) and remove gib. Check gib to

see that set screws do not go all the way

through the gib or dimple the opposite side. If

either of these conditions exist, replace with a

new gib.

Also, check to be sure the ways are clean and

free of pitch and sawdust. Lubricate gib and way

with a good grade of non-hardening grease.

Re-install the gib, making certain that the punch

mark lines up with the locking screw holes. Re-

install gib screws. Repeat steps 3 through 6

above.

Figure 20