Porter-Cable N030679 User Manual

Page 25

25 - ENG

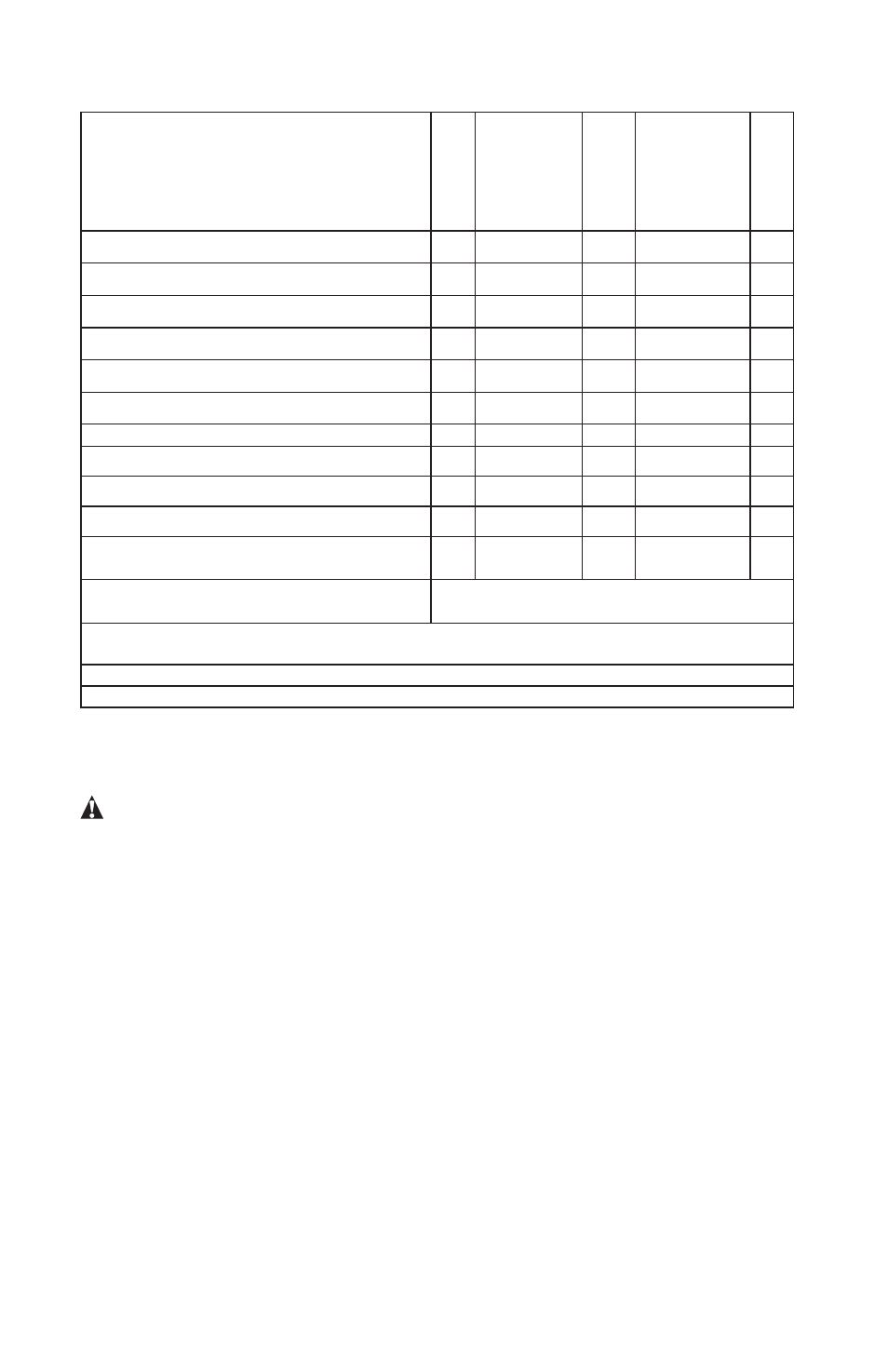

mAINTENANCE ChART

procedure

Daily

50

hours

or

weekly

(w

hic

he

ve

r

comes

first)

100

hours

15

0 h

o

ur

s

or

monthly

(w

hic

he

ve

r

comes

first)

500

h

ours

Clean generator’s exterior

X

Check oil level

X

Change oil

X*(1)

Clean air filter

X(1)

Clean spark plugs

X

Check fuel line, hose clamps and fuel tank

X

Oil leak inspection

X

Sediment cup

X

Clean fuel tank and filter

X(2)

Check for unusual noise/vibration

X

Check and adjust valve clearance

(.15 mm intake, .2 mm exhaust)

X (2)

Prepare unit for Storage

Prepare unit for storage if it is to remain

idle for more then 30 days

* The engine oil must be changed after the first 20 hours or operation. Thereafter change

oil every 150 hours of operation or monthly, whichever comes first.

(1) Perform more frequently in dusty or humid conditions

(2)

Contact a Customer Care Center.

GENERATOR

Cleaning

WARNING: When cleaning, use

only mild soap and a damp cloth on

plastic parts. Many household cleaners

contain chemicals which could

seriously damage plastic. Also, do not

use gasoline, turpentine, lacquer, paint

thinner, dry cleaning fluids or similar

products which may seriously damage

plastic parts. Never let any liquid get

inside the tool; never immerse any part

of the tool into a liquid.

The generator should be kept clean and

dry at all times. The generator should not

be stored or operated in environments

that include excessive moisture, dust

or any corrosive vapors. If these

substances are on the generator, clean

with a cloth or soft bristle brush. Do

not use a garden hose or anything with

water pressure to clean the generator.

Water may enter the cooling air slots

and could possibly damage the rotor,

stator and the internal windings of the

alternator.

FUEL SEDImENT CUp

CLEANING (FIG. 1, 10)

The sediment cup prevents dirt or water,

which may be in the fuel tank from

entering the carburetor. If the engine

has not been run for a long time, the

sediment cup should be cleaned.

1. Turn the fuel shut-off valve (G) to

the OFF position (horizontal to the

ground). Remove the sediment cup

(TT), O-ring (UU) and screen (SS)

as shown.

2. Clean the sediment cup, O-ring

and screen in nonflammable or

high flash point solvent.

3. Reinstall O-ring , screen and

sediment cup.