Patterson-Kelley DVSCM-02 User Manual

Page 6

Thermific

®

Gas-Fired Boiler

Installation

Page 4

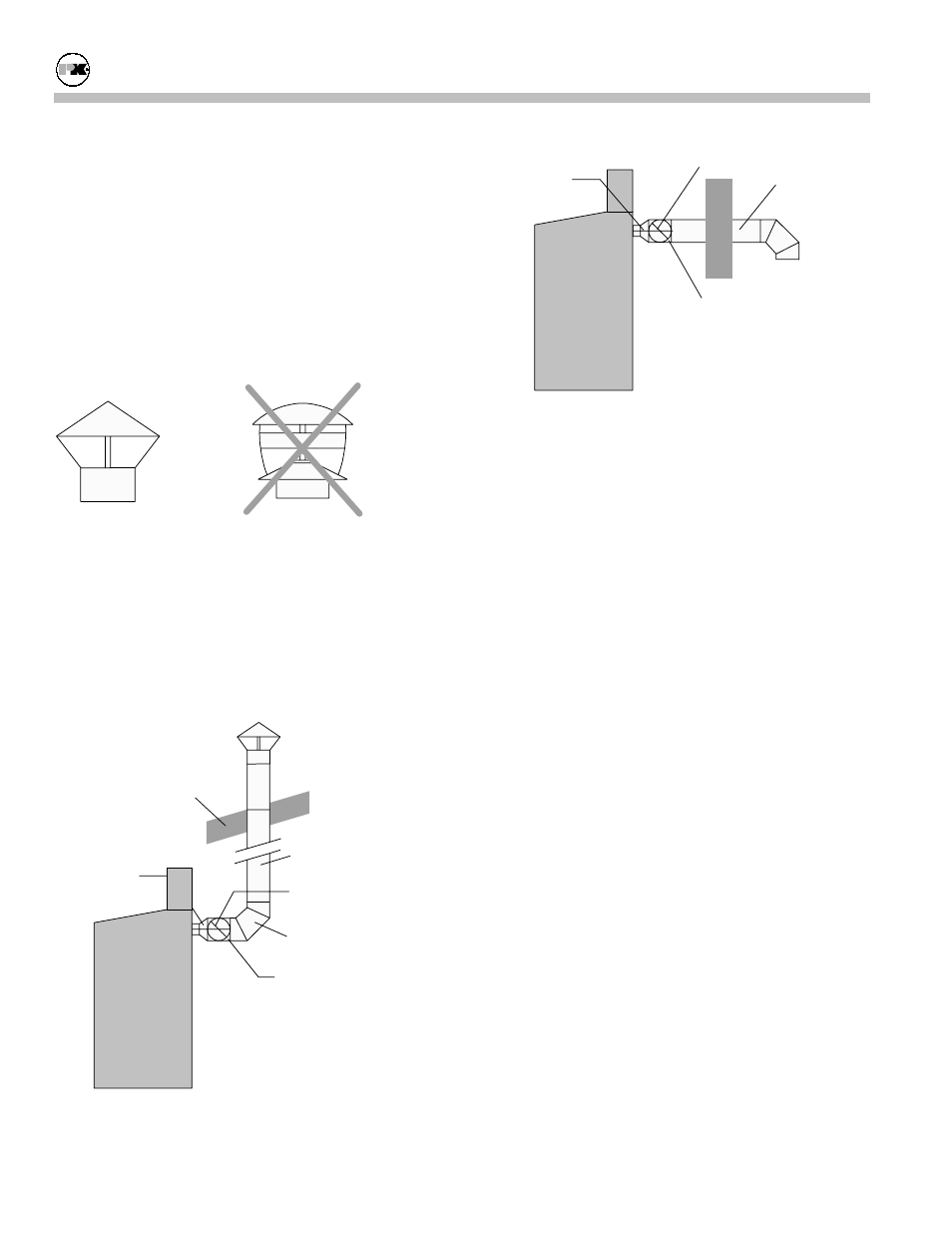

Whichever material is used, the termination must point

down and must be backed by a metal plate secured to

the wall.

Important: The chosen inlet termination must be

included in the calculation of the maximum allowable

equivalent length. See Section 3.4.5 for equivalent

lengths.

Correct rain cap,

unrestricted.

Typical incorrect

rain cap.

If the combustion air inlet duct is routed through the

roof, the termination must be either the same type as

described for a sidewall installation or a rain cap. The

rain cap must be unrestrictive type similar to the

illustration below.

3.2.4 Inlet Duct Assembly at the Boiler

Round

Damper

90 Elbow

o

Transition

Duct

Damper

Housing

Roof

(Roof installation shown.)

Round

Damper

Transition

Duct

Damper

Housing

(Sidewall installation shown.)

The boiler is equipped with a special collar attached to

the air inlet opening on the back of the unit (at the

blower housing on Series 700, 1000, and 1200; at the

back of the cabinet on Series 1500, 1700 and 2000.).

A separate box of accessories is sent with the boiler.

1. Attach the 6 inch diameter end of the custom

transition duct and the extension to the collar using

a minimum of 4 sheet metal screws spaced

approximately at 90 degree intervals. This joint

must then be wrapped with an aluminum tape

backed on the contact side with an adhesive. Do

not use "duct tape."

Important: do not insulate the transition duct or

extension.

Refer to Section 3.2 for instructions for installing and

wiring the auxiliary control panel; it is required if the

optional inlet damper is used.

3.2.4.1 Sealing PVC Duct Tubing to the Inlet Duct

Apply a 3/4" wide x 1/8" thick gasket to the outside

surface edge of the entire circumference of the

transition duct (or extension). A closed cell foam

rubber gasket with pressure sensitive adhesive works

very well. Insert 3/4" of the transition duct into the

PVC duct tubing so that the gasket lines up with the

edge of the PVC tubing. Lay an approximate 3/8"

wide bead of GE RTV-102 silicone sealant, or

equivalent, along the gap between the gasket and

inside wall of the tubing. Allow the silicone sealant to

cure for 24 hours. The cure time can be shortened