0 operation – Patterson-Kelley DVSCM-02 User Manual

Page 11

Thermific

®

Gas-Fired Boiler

Installation/Operation

Page 9

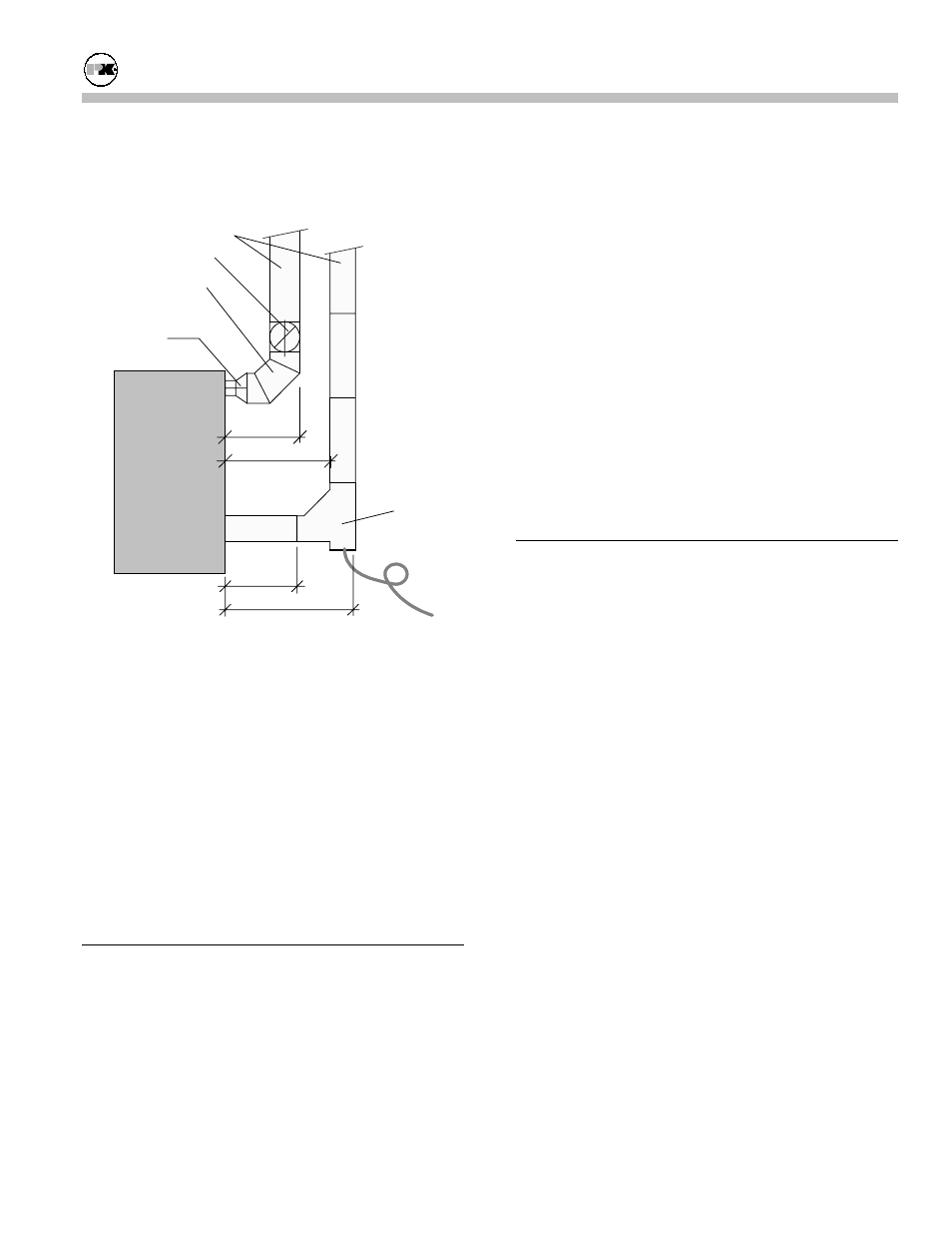

3.4.3.2 Series 1500, 1700, 2000

Air Inlet

Exhaust

Vent

Round

Damper

90 Elbow

o

Transition

Duct

27" Min.

*

31"

*

24"

44" Min.

*

To Drain

Boot Tee/

135 Tee

o

* Dimension shown above is based on 12" round

ductwork.

A minimum of 44 inches is required behind the boiler

to fit the inlet and exhaust connections.

The figure above suggests a duct arrangement using

standard duct pieces that will maintain this minimum

clearance of 44 inches.

4.0 OPERATION

4.1 S

EQUENCE OF

O

PERATION

This sequence applies if the optional inlet damper

assembly and auxiliary control panel are used. If not

the standard Thermific® control sequence applies.

(Replaces step #6 of the Sequence of Operation in the

Installation and Owner's Manual. "TBIG.")

6. The programmer first energizes Terminal 4 which

supplies power to the airflow switch and initiates

the adjustable 120 sec. timer on the time delay

relay. Terminal 4 also supplies power through the

normally closed contacts on the time delay relay

and energizes the coil on the relay in the Auxiliary

Control Panel. The relay will in turn energize the

damper actuator to open the damper. When the

damper is in the full open position, the limit switch

will close and supply power to the contactor for

the blower motor.

During this time (about 20 seconds), the air switch

will indicate low air flow with the "LowAir"

indicator. This indicator will remain on until

sufficient air flow is sensed. If the air flow switch

is not closed in 120 seconds, the time delay relay

will open its normally closed contacts. This will

turn off the blower motor and close the inlet

damper. The "Low Air" indicator will remain

illuminated and the boiler will not operate.

4.2 C

OMBUSTION

O

PERATING

C

ONDITIONS

The combustion air characteristic of the burner in this

boiler is factory set at a condition of utilizing

approximately 50% excess air at room temperature

(70ºF). Therefore, when taking combustion air from

the outdoors in a direct vent system, adjustment of the

combustion air damper linkage should not be made

until the carbon dioxide or oxygen reading is referred

to this condition.

The density of cold outdoor air will be greater than

warm air taken from inside the building. Thus, the

combustion air blower with outdoor air will deliver a

higher air density flow to the burner.

A boiler can be subjected to varying combustion air

temperatures. You must put some thought into the

air/fuel adjustments to prevent hard start and/or light

off rumbling problems. Due to a wide range of

operating conditions, Patterson-Kelley developed a

guide for different conditions.

P-K recommends that the service technician observe

the combustion air temperature range. Identify the

temperature operating conditions of your boiler.

The operational range setting for O

2

is 6.0% to 8.0%.

Insert your 100º F operating temperature range in the

chart below. Start with the Minimum Temperature at

the top of the chart; insert temperatures using 5º F

increments.