0 installation – Patterson-Kelley DVSCM-02 User Manual

Page 5

Thermific

®

Gas-Fired Boiler

Installation

Page 3

Do not manifold two (2) or more units into a common

sidewall vent system without provisions for additional

forced draft.

3.0 INSTALLATION

3.1 C

OMPONENTS

P

ROVIDED

The direct vent/sealed combustion option is shipped

with the following items shipped loose for field

installation:

Custom 6 inch diameter to 12 inch diameter

transition duct with extension, for attachment to

the combustion air inlet on the boiler.

A 12" inlet damper assembly with actuator and

limit switch mounted to the damper shaft.

Auxiliary Control Panel to operate the inlet

damper assembly.

The inlet damper assembly and control panel will

prevent the flow of cold air through the boiler during

the off cycle and prevent freeze up and "off cycle"

losses. The use of these two items is optional.

3.2 C

OMBUSTION

A

IR

I

NLET

S

YSTEM

Note:

3.2.1 System Design - Pressure Drop

The air inlet duct system shall be designed for a

maximum pressure drop of 0.05" W.C. taking into

account the equivalent length of all fittings. Refer to

Section 3.4.5 for equivalent length of fittings.

3.2.2 Inlet Duct

Materials shall be single wall galvanized duct

(minimum thickness 26 gauge) or PVC duct tubing

(0.187 inch wall thickness) only. No substitutions.

3.2.2.1 Single Wall Galvanized Duct

Proper sealing of the tubing is necessary to prevent

flow of combustion air from conditioned space. If

single wall galvanized tubing is used, GE RTV 102

silicone sealant, or equivalent, must be used on each

circumferential and horizontal joint before joining

together. At least 24 hours must be allowed for cure

of this sealant and proper bond. Cure time can be

reduced through the application of heat (See

instructions provided with the sealant). After the cure

period, each joint must be wrapped with an aluminum

tape which is faced on the contact side with an

adhesive.

3.2.2.2 PVC Duct

Proper sealing of the tubing is necessary to prevent

flow of combustion air from conditioned space.

The installation must follow the vent manufacturer's

instructions in all respects including proper joining and

sealing of the tubing and fittings. Clearances to

combustible materials and installation of firestops

must conform to applicable codes.

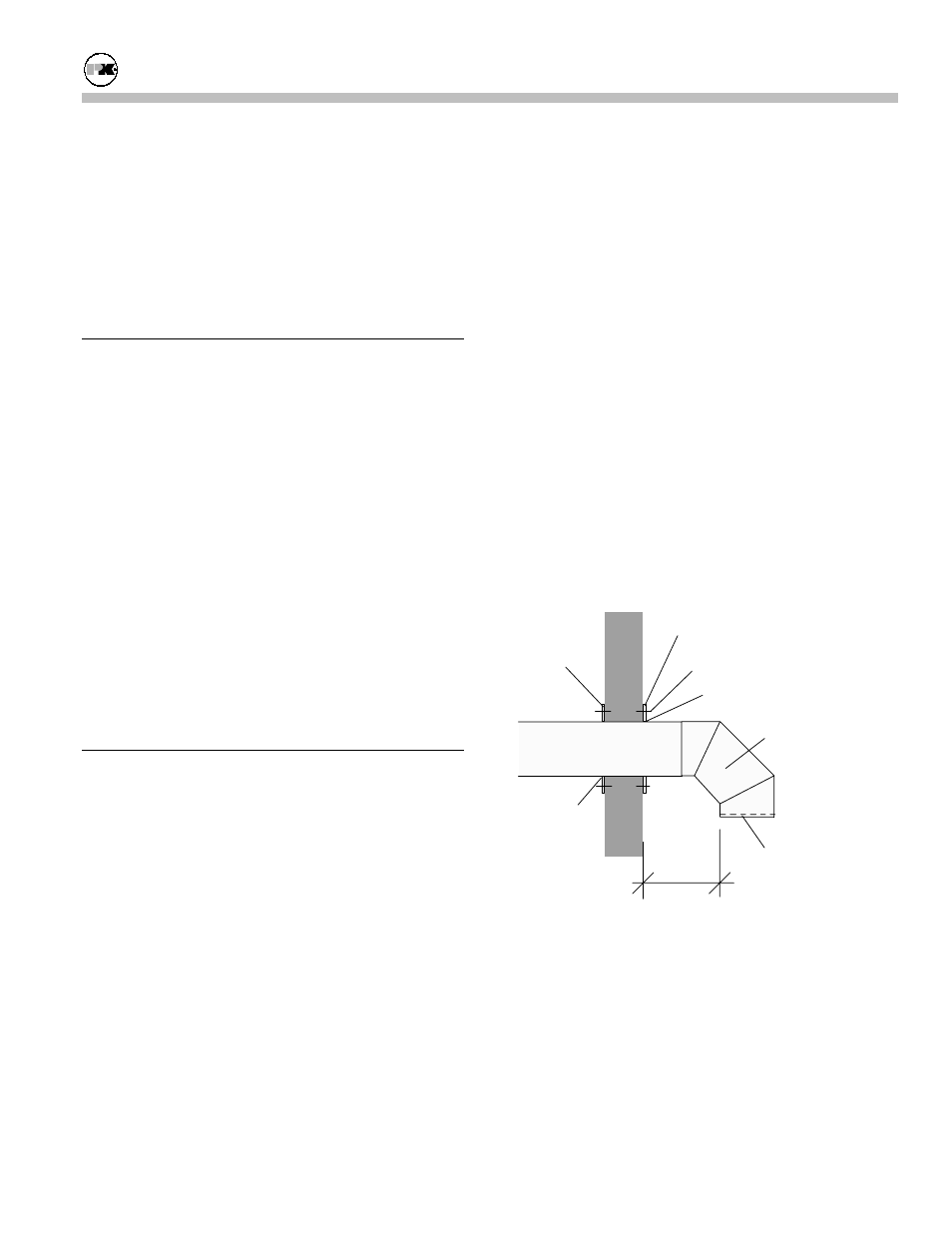

3.2.3 Air Inlet Termination

12" Min.

Recommended

Termination

(refer to text).

Sealant

Centering

Support

Plate

Outside Plate

Cover Plate

Fastener

Sealant

Field Provided

Inlet Screen

The boiler combustion air inlet duct must be fitted

with a termination device meeting the requirements of

ANSI Z21.13. There are four recommended sidewall

terminations:

• Double wall B vent 90 degree elbow, or

• Two double wall B vent 45 degree elbows, or

• Schedule 40 PVC 90 degree elbow, or

• Properly engineered intake louver screen.