Troubleshooting – Powermatic PM3000 User Manual

Page 25

25

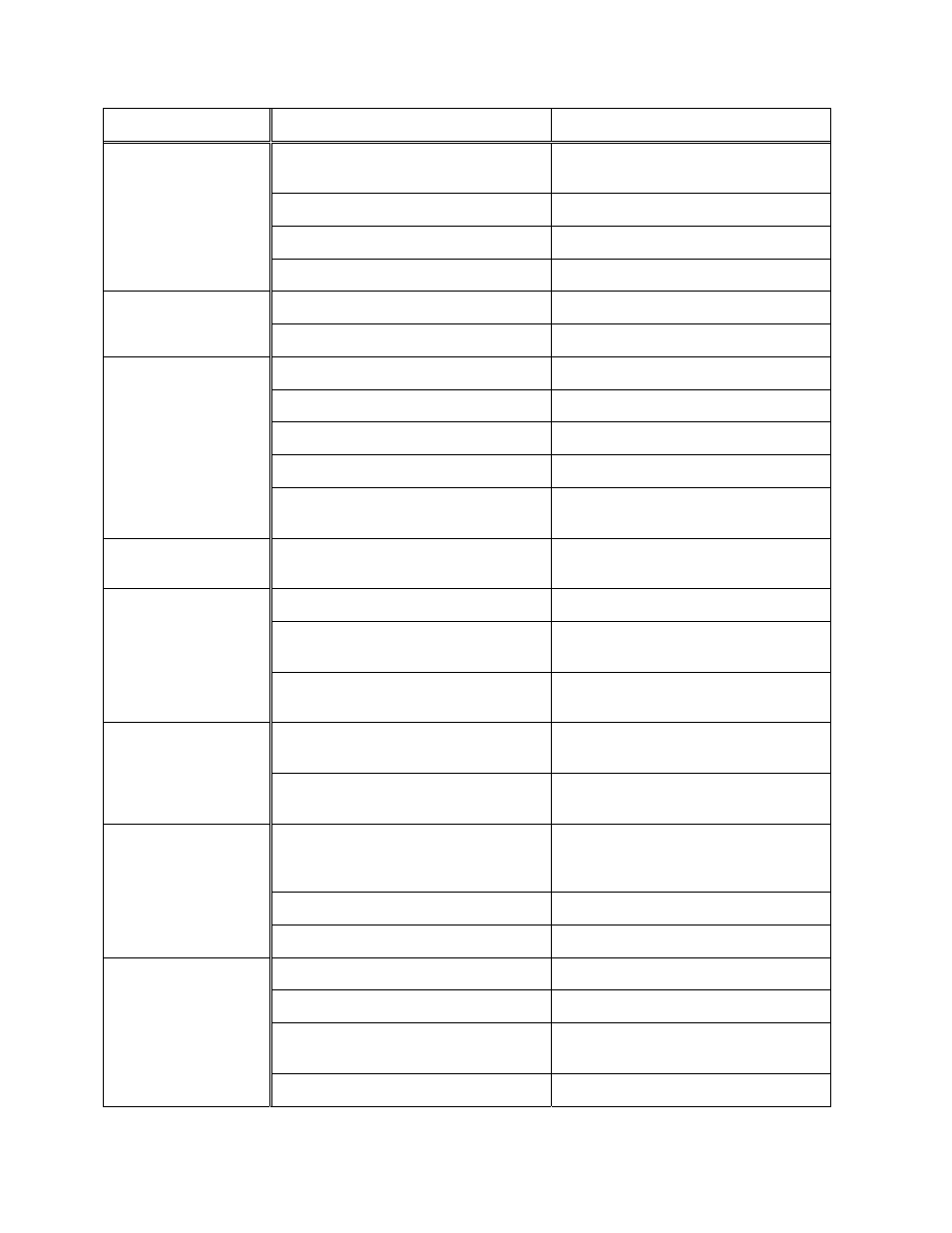

Troubleshooting

Trouble Probable

Cause

Remedy

Excessive vibration.

Tilt or raising clamp knobs not

tightened.

Tighten knobs.

Blade out of balance.

Change blade. [page 10]

Bad motor.

Replace motor.

Loose arbor or motor sheave.

Tighten set screws.

Cuts out-of-square

when crosscutting.

Miter gauge out of adjustment.

Reset pointer. [page 15-16]

Miter slot misaligned.

Realign table. [page 14]

Motor stalls or

workpiece binds or

burns.

Excessive feed.

Reduce feed.

Bad motor.

Replace motor.

Dull or incorrect blade.

Replace blade. [page 10]

Miter slot misaligned.

Realign miter slot. [page 14]

Fence misalignment.

Realign fence. [see Fence Manual

No. M-2195079Z]

Cuts not true at 90 or

45 degrees.

Stop screws not set properly.

Readjust stop screws. [page 15]

Tilt or saw raising

handwheels difficult

to turn.

Lock knob not released.

Loosen lock knob.

Worm and worm gear segment caked

with sawdust and pitch.

Clean and re-grease.

Worm and worm gear segment out of

alignment.

Realign worm and worm gear

segment.

Motor overheats.

Motor overloaded.

Correct overload condition such as

reducing the feed rate.

Improper cooling of motor.

Clean sawdust from fan and duct

areas of motor.

Motor starts slowly or

fails to come up to

speed.

Low voltage.

Request voltage check from power

company and correct low voltage

condition.

Centrifugal switch not operating.

Replace switch.

Bad motor.

Replace motor.

Motor fails to develop

full power.

Power line overloaded.

Correct overload condition.

Undersize wires in supply system.

Increase supply wire size.

Low voltage.

Request voltage check from power

company and correct condition.

Bad motor.

Replace motor.