Safety rules – Powermatic 2700 User Manual

Page 6

6

Warning

Short stock – Never shape stock less than 12

inches in length without special fixtures. Where

practical, shape longer stock and cut to size.

12 inch rule – When shaping, never allow your

hands to come closer than 12 inches to the

cutters.

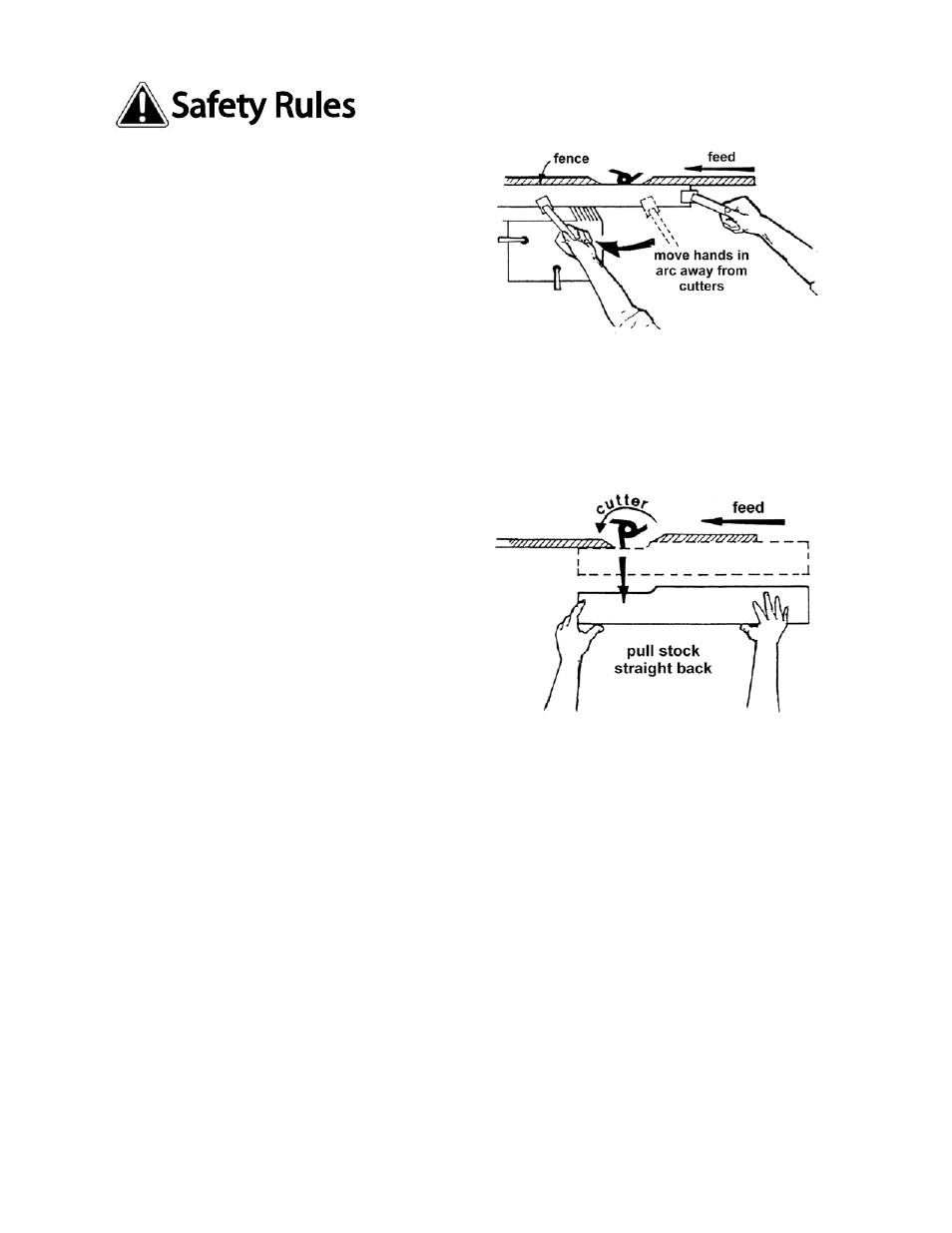

Hand safety – Never pass the hands directly

over, or in front of, the cutters (Figure A). As one

hand approaches the 12 inch radius point, remove

it (or the push stick) in an arc motion and

reposition hands 12 inches beyond the cutters.

Blind cut – When blind cutting, the workpiece is

positioned on top of the template. This keeps the

cutter(s) cutting only the underside of the

workpiece and provides a "distance" guard for the

operator.

Cutter Clearance – With the power disconnected,

always rotate the spindle by hand with any new

set-up to ensure proper clearance with the cutters.

At the same time, check to be sure the cutterhead

is turning in the correct direction.

Stock feed – Feed stock opposite to the direction

of the cutter rotation (Figure B). Never back stock

out of the cutter once the cut has been started.

Instead, pull the stock straight out away from

cutter and begin the cut again.

Guide pin – Whenever possible, use a guide pin

when performing pattern shaping and collar

shaping operations.

Tool maintenance – Clean and sharp tools give

safer and better performance. Dull tools can

cause kickbacks and excessive chatter. Before

making a cut, always check the condition and

adjustment of the tools. Never use a tool that is

not balanced and rated for the selected RPM.

Spindle speed – Do not operate tools at speeds

higher than rated by the manufacturer.

Cutter selection – Use only those cutters

designed to be used on the machine, and mount

only safety type cutters on the spindle.

Stock condition – The danger of kicked-back

stock can occur when the stock has knots, holes,

or foreign objects such as nails. Warped or in-wind

stock should first be jointed on one surface before

attempting to use it on the shaper.

Figure A

Figure B