Operating controls, Start/stop, Safety key – Powermatic 2700 User Manual

Page 19: Digital readout

19

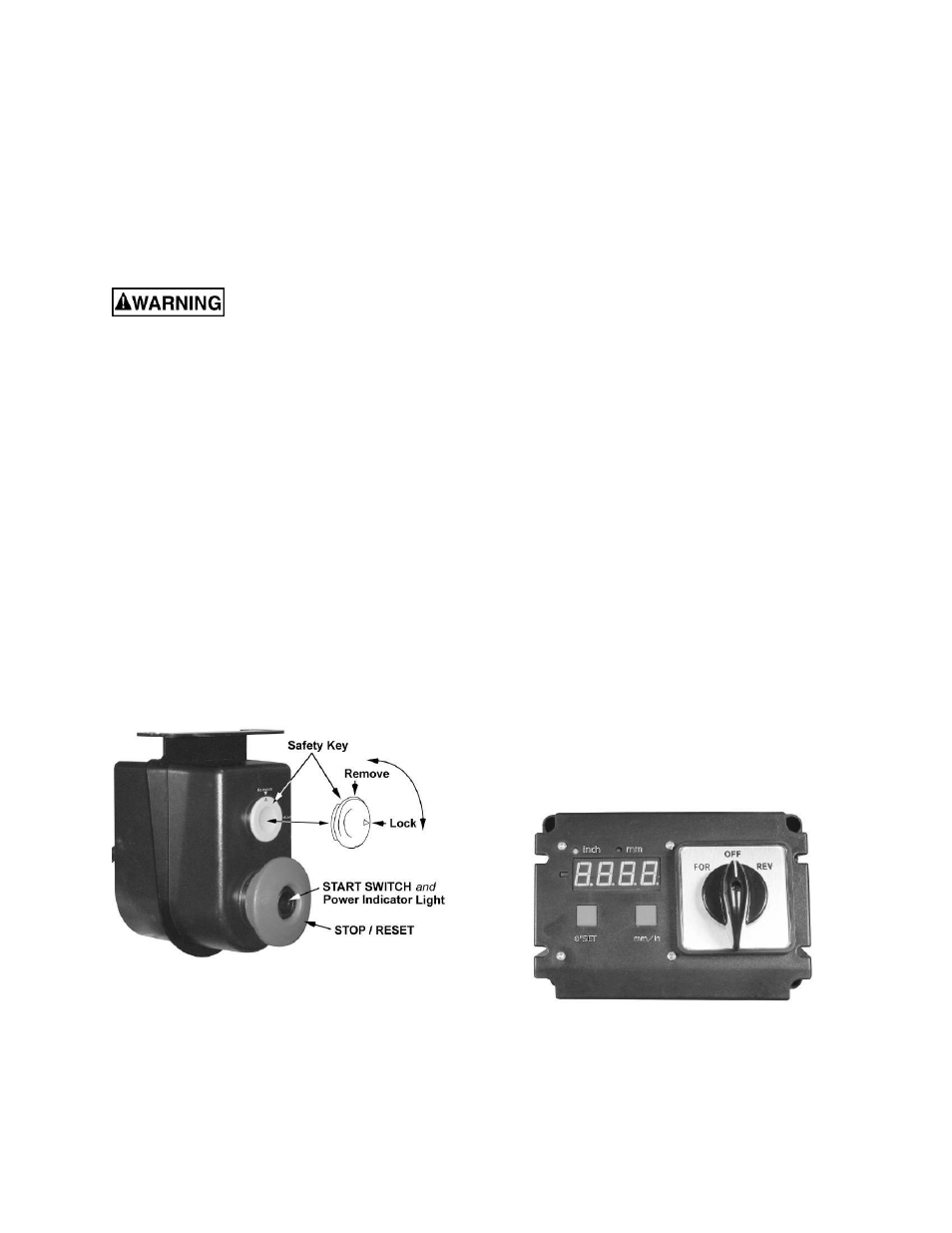

Operating Controls

Start/Stop

Power Indicator Light – The start switch has a

power indicator lamp which is on whenever

there is power connected to the shaper, not

just when the shaper is running. Do not assume

that no light means there is no power to the

machine. If the bulb is bad, there will be no

indication. Always check before use.

Do not rely that no light

means no power to the machine. Always

check for power first. Failure to comply may

cause serious injury!

Referring to Figure 20:

Start – Press the green start switch (see Note).

When power is connected to the machine, the

green light is always on regardless of whether

the shaper is running or not.

Note: In addition, the switch on the digital

readout must be set to forward (or reverse) and

the cabinet door must be closed.

Stop – Press the red switch to stop.

Reset – In the event that the shaper stops

without pressing the stop button, as the result of

a tripped fuse or circuit breaker, etc.:

1. Press red button to reset

2. Press the green button to restart the

machine.

Figure 20

Safety Key

The start/stop switch on the Model PM2700

comes equipped with a magnetic safety key.

When in place on the switch as shown in Figure

20 the magnetic safety key trips a relay which

will allow the machine to start and stop when the

respective switches are pressed. Being

magnetic, the lock can be removed to make the

machine inoperable and can be hidden for safe

storage by attaching it underneath the rail or

another magnetic surface.

When using the shaper, place the key on the

switch cover lining up the arrow on the key with

the REMOVE arrow on the cover. Then rotate

the key so the arrow lines up with the LOCK

arrow. This will prevent the safety key from

coming loose from vibration when the machine

is in use.

Digital Readout

The digital readout (Figure 21) is used for

making incremental spindle height adjustments

where applicable, if multiple shaping/cutting

passes are to be performed on a given work-

piece.

Set the digital readout as follows:

1. Set the desired spindle height for the

workpiece to be cut.

2. Supply power to the machine so the digital

display is lit.

3. Select inch or mm by momentarily

depressing the button on the right.

4. Press

the

0" SET button for approximately

two seconds.

The digital display resets to zero, which is your

reference point. When the spindle is raised or

lowered (front handwheel), the change is relative

to this reference.

If this feature is used, the display should be

reset to zero for each new cutting operation.

Figure 21