Verify output voltage of d-to-a board – Milnor BICWUT01 User Manual

Page 8

Troubleshooting Basket Speed Errors on Single-motor Washer-extractors

PELLERIN MILNOR CORPORATION

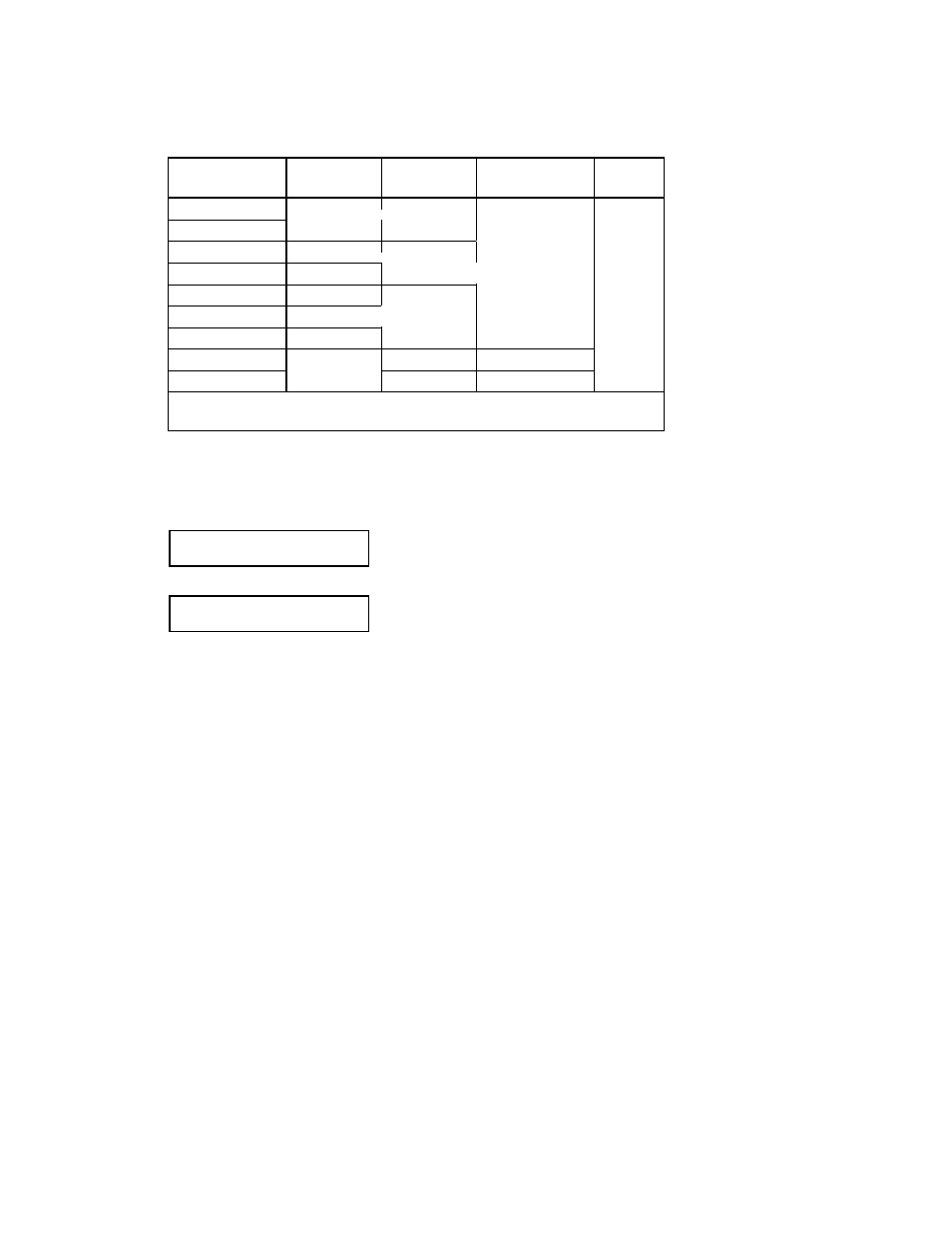

Table 1: Model-Specific Data

Machine Model

Maximum

Frequency

Maximum

Wash RPM

Counts per RPM

(C/RPM)

Offset (D)

30022F_W

30022X_W

155

40

36030F_S

186

36030F_W

205

43

42026V_W

155

42032F_S

178

42032F_W

195

40

5

48040F_W

38

6

68036F_N

170

32

7

15

Important: Values shown are subject to change without notice. Contact Milnor

Customer Service for verification.

Note 1: The counts and offset values are configurable in controller software WUWESME, used in single-

motor E-style and divided cylinder washer-extractors. Contact your dealer or the Milnor service department

for assistance with these machines.

Display or Action

Explanation

10:38 F0005S03 02:37

0195 RPM=A029/D030

The rightmost number of the bottom line indicates the desired

(programmed) basket speed for this step. This value matches the

value programmed in the wash formula.

10:38 F0005S03 02:37

0195 RPM=A029/D030

The middle number of the bottom line indicates the current

calculated basket speed. Input/output board #1 determines the

time between each main pulley spoke passing the photoeye and

reports this data to the processor board at each communication

cycle, which is usually more often than once per second. The

processor board filters the raw data from the input/output board

and displays the most recent valid value.

Tip:

Large variations in the achieved RPM value are possible early in extract steps because the valid

range includes values from 0 RPMs to the maximum extract RPM of the machine. These

variations have no effect on how the machine operates because of the frequency with which new

data is reported.

4.

Verify Output Voltage of D-to-A Board

If the microprocessor is displaying the correct calculated digital value, the next step is to verify

that the digital-to-analog board is putting out the appropriate signal voltage.

1. Calculate the voltage of the signal that the D-to-A board should deliver to the inverter:

V

d

= C

d

/ 409.5

Where:

V

d

= Desired voltage

C

d

= Desired counts per RPM

For example, assume the machine is configured as a 48040F_W and the desired wash speed

is 24 RPMs.

a. From Table 1, we see that this machine model makes six counts per revolution and has an

offset of 15.