Patterson-Kelley TBIG-03 User Manual

Page 8

Gemini™ Twin-Fuel Gas-Fired Boiler

Gas Pressure Adjustment

Test of Motorized Gas Valves

4.2 G

AS

P

IPING

Before making the gas hook-up, make sure the boiler

is being supplied only with the fuels shown on the

boiler nameplate. The boiler is designed to operate on

vaporized natural gas and propane only. Do not use

any type of liquid fuel. Do not attempt to fuel the

boiler with MAPP gas, sewage gas, coal gas, or other

fuels.

Gas train connection sizes are shown in the Gas Train

Connection table on the previous page for the different

models available.

The boiler shall be installed such that the gas ignition

system components are protected from water (drip-

ping, spraying, rain, etc.) during appliance operation

and service (circulator replacement, control replace-

ment, etc.).

The two gas pressure regulators supplied with the

boiler are set during a factory fire-test to provide the

proper pressure to the main burner: 6 inches W.C. in-

let pressure to the regulators for both natural gas and

propane.

The gas train components are designed to handle a

maximum inlet pressure of 14 inches W.C.(1/2 psig).

If the available gas pressure exceeds 14 inches W.C.

on either the natural gas or propane supply a suitable

intermediate gas pressure regulator of the "lock up"

type must be provided to reduce the pressure to less

than 14 inches W.C. All boilers are designed to oper-

ate at rated input with a minimum inlet pressure of 6

inches W.C. with natural gas, 6 inches W.C. with LP

gas.

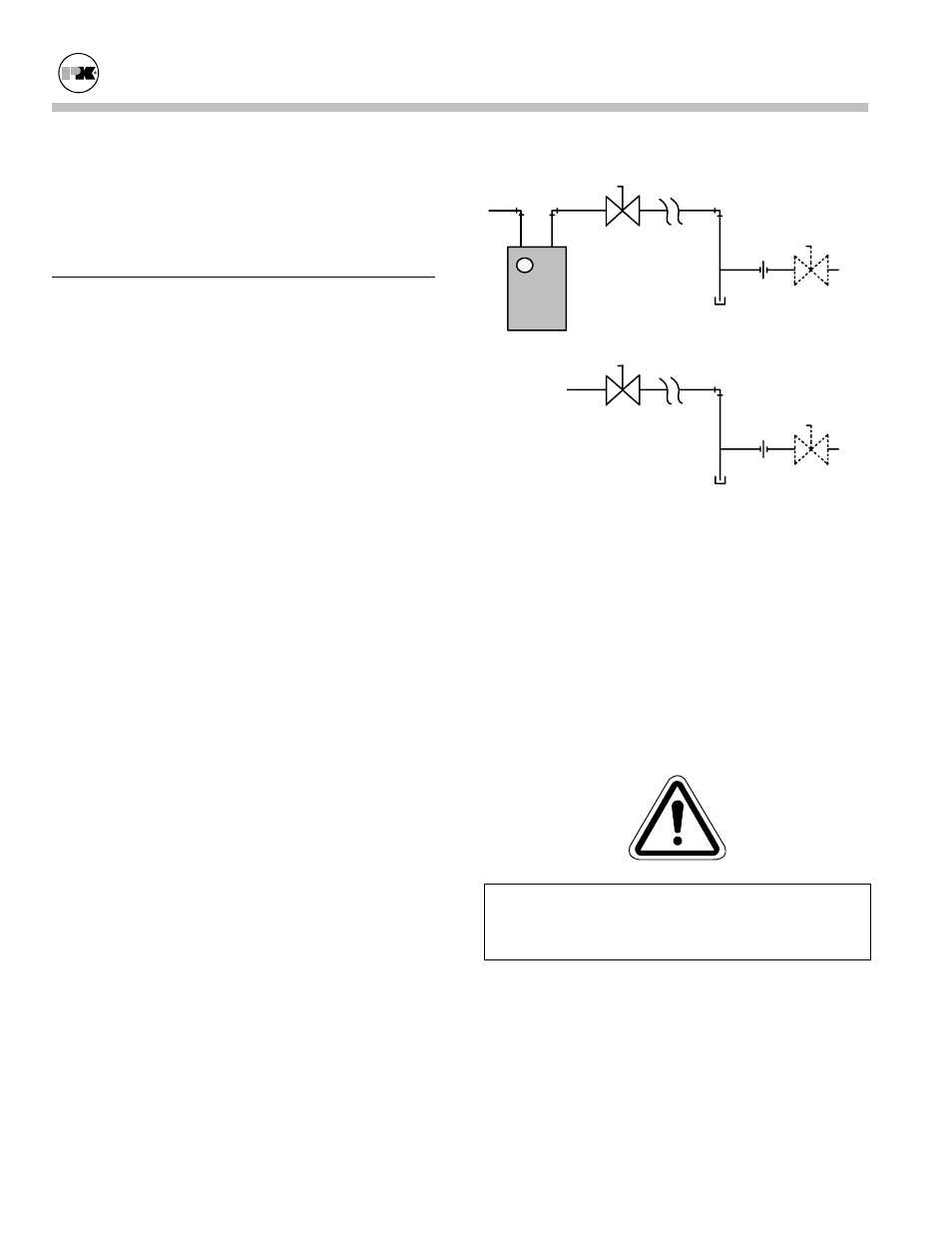

shutoff

(on boiler)

union

drip leg

remote gas shutoff

(not supplied)

meter

natural gas

supply

propane

supply

shutoff

(on boiler)

union

drip leg

remote gas shutoff

(not supplied)

Figure 4-2 Gas Supply Piping

(Refer to table above for connection sizes.)

Install a sediment trap (drip leg) and a union connec-

tion ahead of the primary manual shutoff valves on the

boiler as shown in the figure above.

All gas piping must be installed in accordance with

National Fuel Gas Code, ANSI Z223.1, latest edition,

and any other local codes which may apply; in Canada

gas piping must be installed in accordance with CAN-

B 149.

General Warning

Warning! All threaded connections must be made us-

ing a pipe compound that is resistant to the action of

liquefied petroleum gases. Do not use Teflon

ä tape

on gas line threads.

The boiler and all gas piping connections must be

pressure tested and must be checked for leaks before

being placed into service. Test with compressed air or

gas if possible.

The boiler must be disconnected at both boiler manual

- 6 -